A heat exchanger, a charger cabinet and a charger using the heat exchanger

A technology for heat exchangers and cabinets, which is applied in the fields of heat exchangers, charger cabinets and chargers. It can solve the problems of affecting the heat exchange effect, poor heat dissipation effect, and large heat transmission distance, so as to achieve high heat transfer efficiency and improve heat dissipation. Good effect and heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

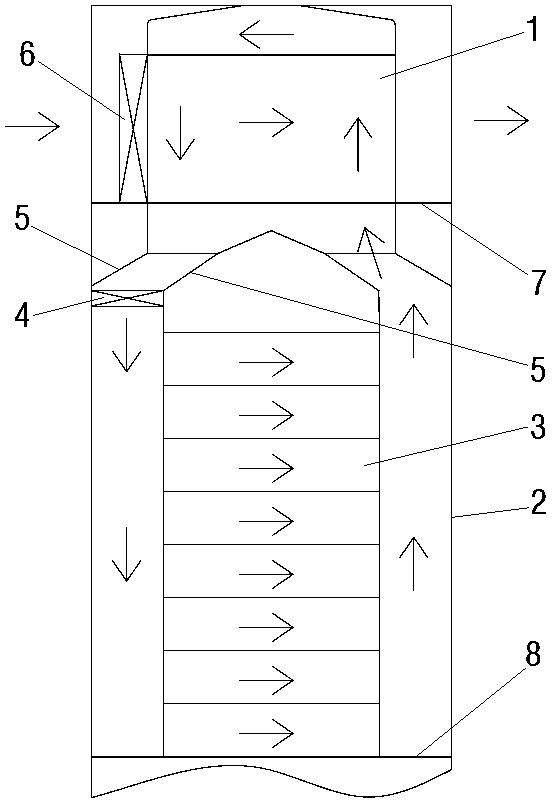

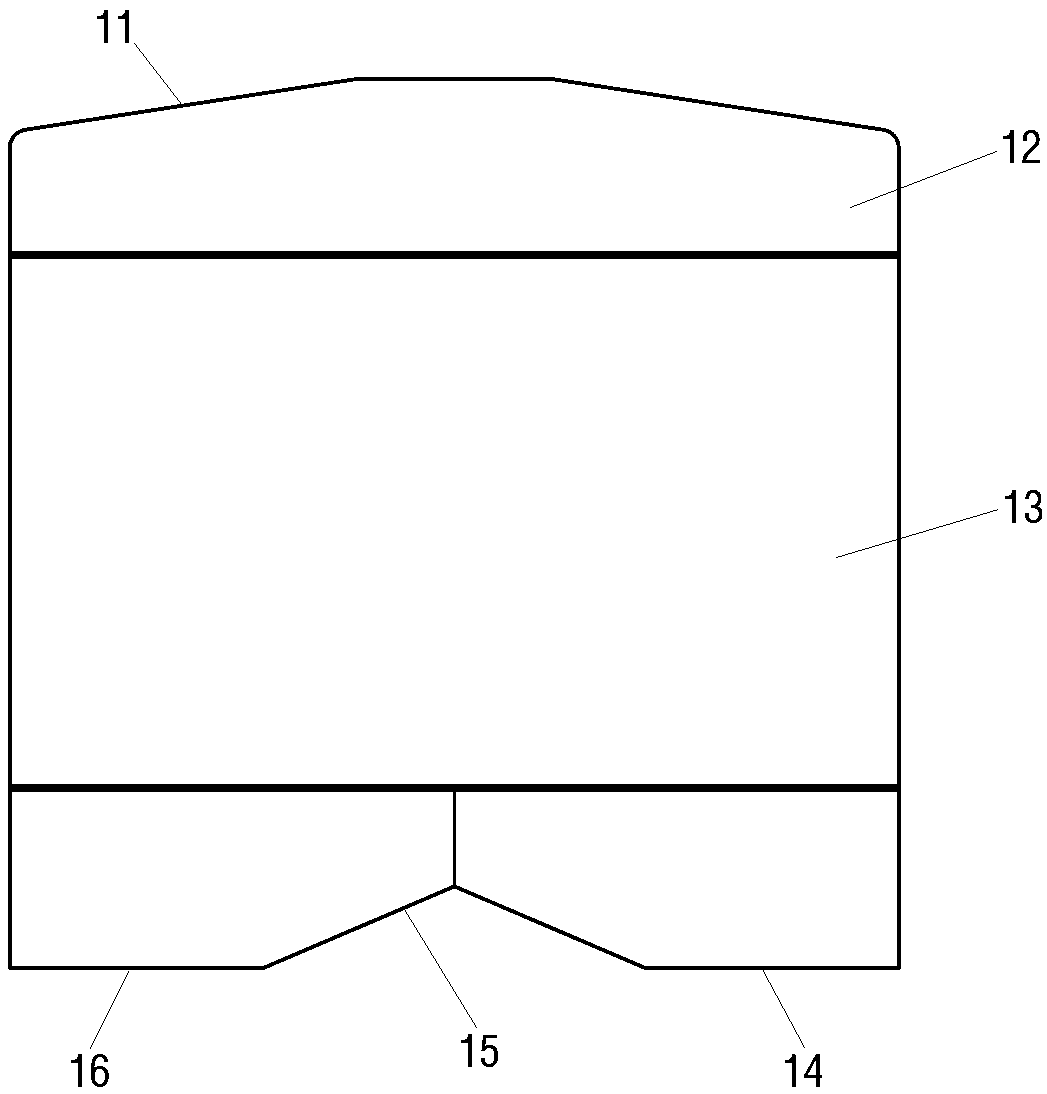

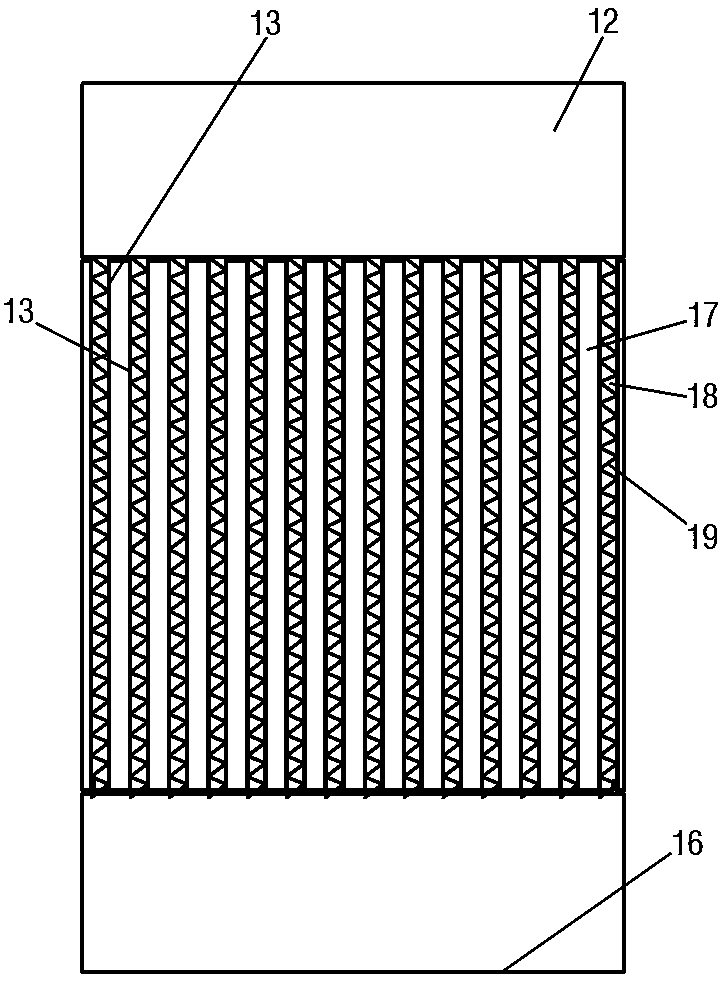

[0037] An example of a charger is Figure 1~Figure 4 As shown, it includes a cabinet 2, a charging module 3 is arranged in the cabinet 2, a heat exchanger 1 is arranged on the top of the cabinet 2, and the heat exchanger 1 includes a casing 11, and 28 cells are arranged in the casing 11 and arranged side by side at intervals along the thickness direction. The heat conduction wall 13 of the cloth, any two adjacent heat conduction walls 13 are combined to form a heat conduction channel, and the heat conduction channel is divided into a hot channel 17 and a cold channel 18, and the hot channel 17 and the cold channel 18 are arranged alternately along the arrangement direction of the heat conduction wall 13 , and there are 13 hot aisles 17 and 14 cold aisles 18.

[0038] The extension direction of the hot aisle 17 is the up-down direction, and the extension direction of the cold aisle 18 is the left-right direction. Both the hot aisle 17 and the cold aisle 18 are provided with alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com