Poly(vinyl acetate) dispersion, and paint formulation comprising thereof

一种分散体、单体的技术,应用在涂层等方向,能够解决不善于提供竞争性可洗性和早期抗粉化性、油漆稳定性问题等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation of paint formulations involves the process of selecting and mixing the appropriate paint ingredients in the correct proportions to provide a paint with specific processing and handling characteristics and a final dried paint film with the desired properties.

[0040] The paint formulations can be applied by conventional application methods such as brushing, rolling and spraying methods such as air atomized spray, air assisted spray, airless spray, high volume low pressure spray and air assisted airless spray .

[0041] Suitable substrates for paint application include concrete, cement board, medium density fiberboard (MDF) and particle board, gypsum board, wood, stone, metal, plastic, wallpaper, and textiles, among others. Preferably, all substrates are pre-coated with a water-based or solvent-based primer.

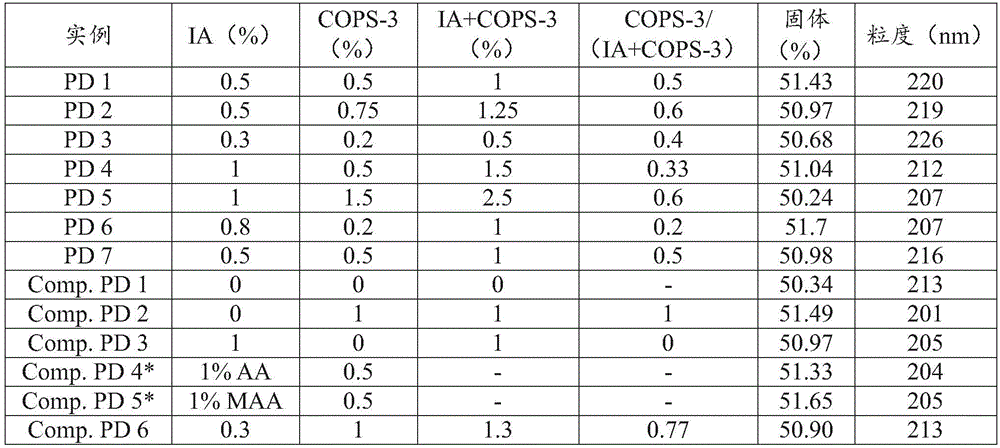

example

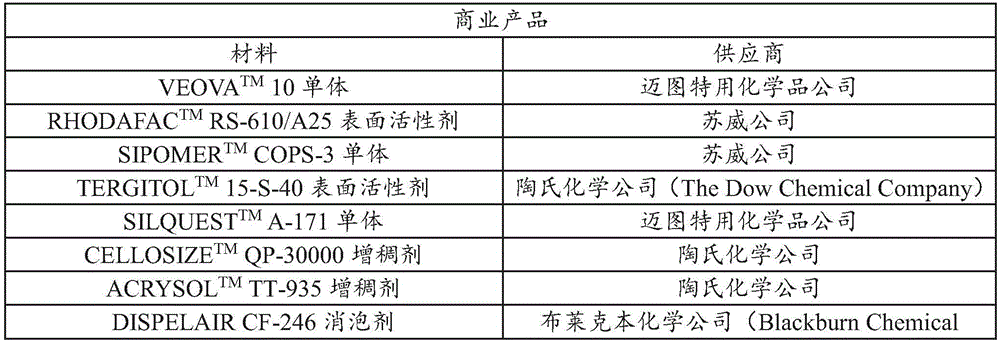

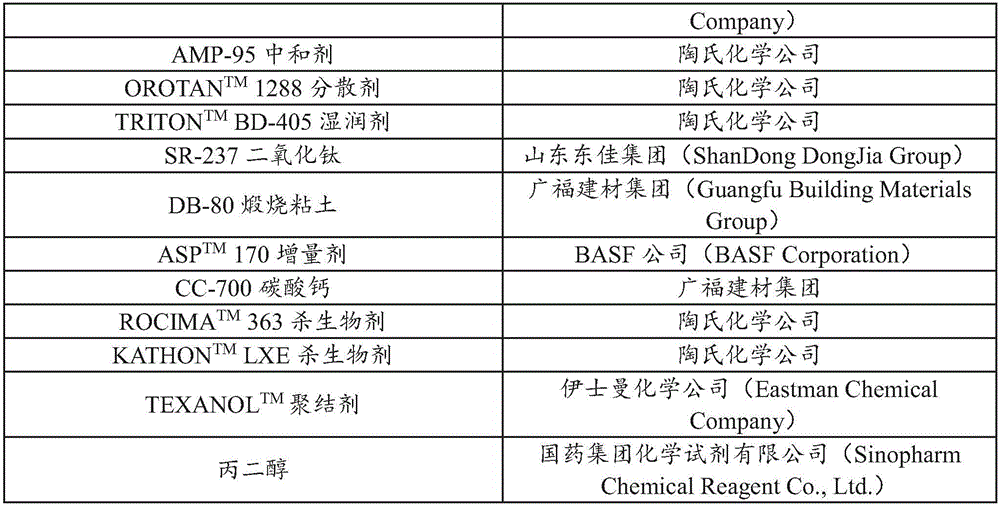

[0043] I. Raw materials

[0044] abbreviation Chemical material BA Butyl acrylate VA vinyl acetate IA itaconic acid SVS Sodium vinyl sulfonate AMPS Sodium 2-acrylamido-2-methyl-1-propanesulfonate SPS sodium persulfate t-BHP tert-butyl hydroperoxide IAA isoascorbic acid EDTA Ethylenediaminetetraacetic acid

[0045]

[0046]

[0047] II. Test procedure

[0048] 1. Washability

[0049] Panels were scraped with paint starting from the fixed end of the panel using a 175um film caster. The paint drawdowns were then air dried horizontally for 7 days in a constant temperature room (CTR). The brushes were submerged in soapy water overnight prior to use and then placed in the holder with the bristle side of the brush down to begin the test. The wiping medium is a 0.5% soap solution. More soap solution can be added to paint scrapers as needed. The number of cycles used to completely remove the paint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com