Insulator

A vibration isolation and stop surface technology, applied in the direction of pipe components, vehicle components, engine components, etc., can solve problems such as abnormal noise, and achieve the effect of improving suppression efficiency, significant nonlinear characteristics, and suppressing abnormal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

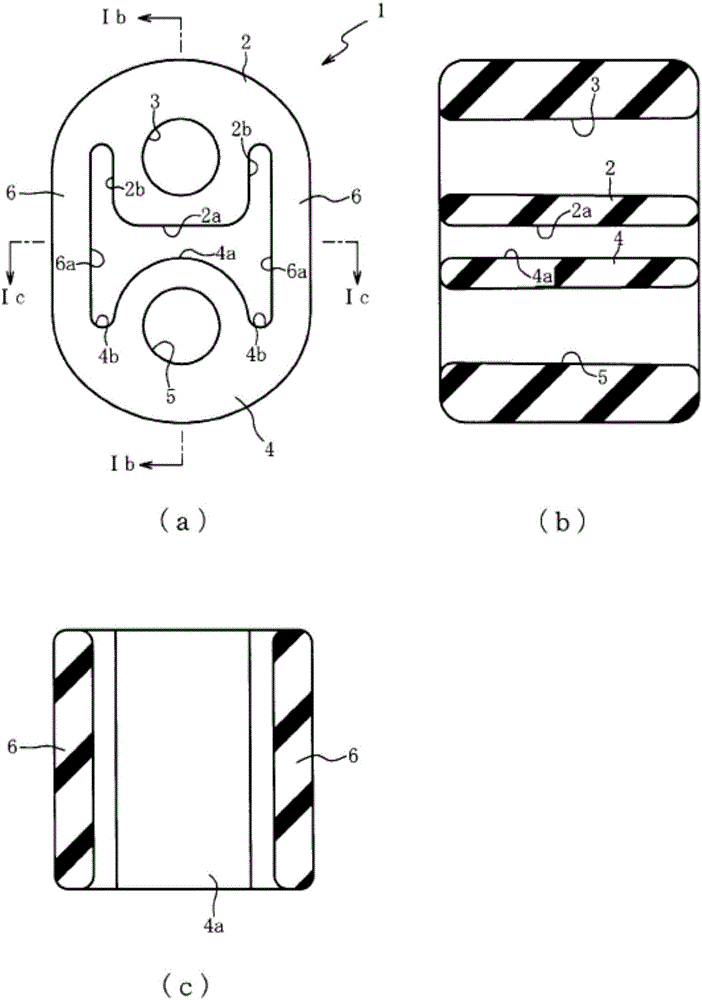

[0028] Next, preferred embodiments of the present invention will be described with reference to the drawings. refer to figure 1 The vibration isolator 1 according to the first embodiment of the present invention will be described. figure 1 (a) is a front view of the vibration isolator 1 of the first embodiment, figure 1 (b) is along figure 1 The sectional view of the vibration isolator 1 of the Ib-Ib line of (a), figure 1 (c) is along figure 1 (a) Cross-sectional view of the vibration isolator 1 along line Ic-Ic.

[0029] Such as figure 1 (a) to figure 1 As shown in (c), the vibration isolator 1 is a substantially elliptical member when viewed from the front, and is integrally formed of a self-lubricating rubber-like elastic body. As a self-lubricating rubber-like elastic body, a type in which a lubricant such as fatty acid amide oozes out on the surface of the rubber-like elastic body to reduce the friction coefficient of the surface and exhibit lubricity is used. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com