Manufacture method for caries prevention candy and lollipop thereof

A manufacturing method and candy technology, which are applied in the field of manufacturing methods and products prepared by the manufacturing method, and can solve problems such as problematic effects, weak broad-spectrum antibacterial ability, and limited antibacterial ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

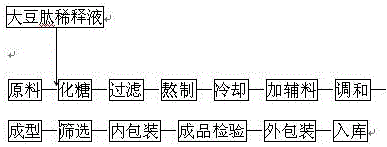

[0028] The lollipop for preventing dental caries, its production process is as follows:

[0029] 1. Using soybean protein processing to obtain concentrated soybean peptide crystalline powder with a content of 90-100%.

[0030] 2. Dissolve the concentrated crystalline powder of soybean peptide with a content of 90-100% in pure water, and dilute it to a soybean peptide solution with a concentration of 0.0001-1% (mass percentage) (solutions with different ratios for different types of candy), and use the above The diluent (as water for preparation) is prepared with maltodextrin, and then the dextrin is coated on the surface of the lollipop, dried and packaged.

[0031] 3. It is also possible to use the prepared diluent as raw material water in the process of sugar melting in the lollipop manufacturing process, so that the soybean peptide can be evenly distributed in the syrup.

[0032] 3. Other production processes of lollipops are no different from normal production processes. ...

Embodiment 2

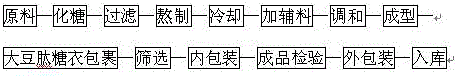

[0040] The production process of hard candies for preventing dental caries is as follows:

[0041] 1. Using soybean protein processing to obtain concentrated soybean peptide crystalline powder with a content of 90-100%.

[0042] 2. Dissolve the concentrated crystalline powder of soybean peptide with a content of 90-100% in pure water, and dilute it to a soybean peptide solution with a concentration of 0.0001-1% (mass percentage) (solutions with different ratios for different types of candy), and use the above Diluent (as preparation water) is prepared with maltodextrin, and then the dextrin is coated on the surface of hard candy, dried and packaged.

[0043] 3. It is also possible to use the above-mentioned diluted solution as raw material water in the sugar melting link of the hard candy manufacturing process, so that the soybean peptide can be evenly distributed in the syrup.

[0044] 4. Other production processes of hard candy are no different from normal production proces...

Embodiment 3

[0052] The production process of soft candies for preventing dental caries is as follows:

[0053] 1. Using soybean protein processing to obtain concentrated soybean peptide crystalline powder with a content of 90-100%.

[0054] 2. Dissolve the concentrated crystalline powder of soybean peptide with a content of 90-100% in pure water, and dilute it to a soybean peptide solution with a concentration of 0.0001-1% (mass percentage) (solutions with different ratios for different types of candy), and use the above The diluent (as water for preparation) is prepared with maltodextrin, and then the dextrin is coated on the surface of the soft candy, dried and packaged.

[0055] 3. It is also possible to use the above-mentioned diluted solution as raw material water in the sugar melting link of the soft candy manufacturing process, so that the soybean peptide can be evenly distributed in the syrup.

[0056] 4. Other production processes of hard candy are no different from normal produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com