Method for determining positions of all areas of cross section of industrial pure-titanium fusion welding joint

A technology of industrial pure titanium and fusion welding joints, which is applied in the field of material welding and metallurgy, can solve the problems that joints do not often undergo heat treatment, and no one has noticed the positive effects of moderate heat treatment heat-affected zone and melting zone, etc. The method is simple and reliable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

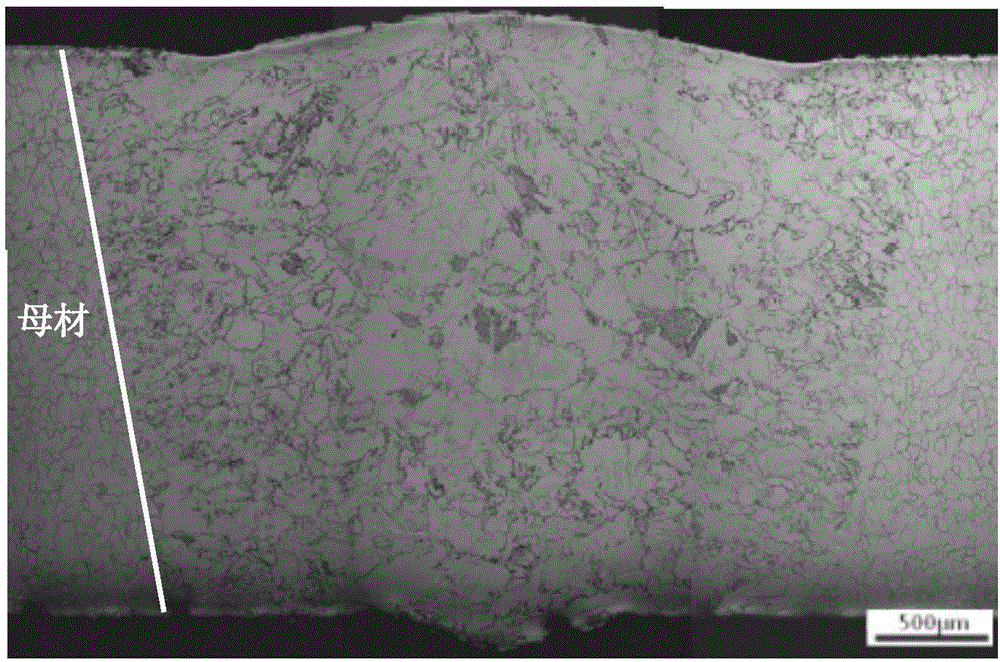

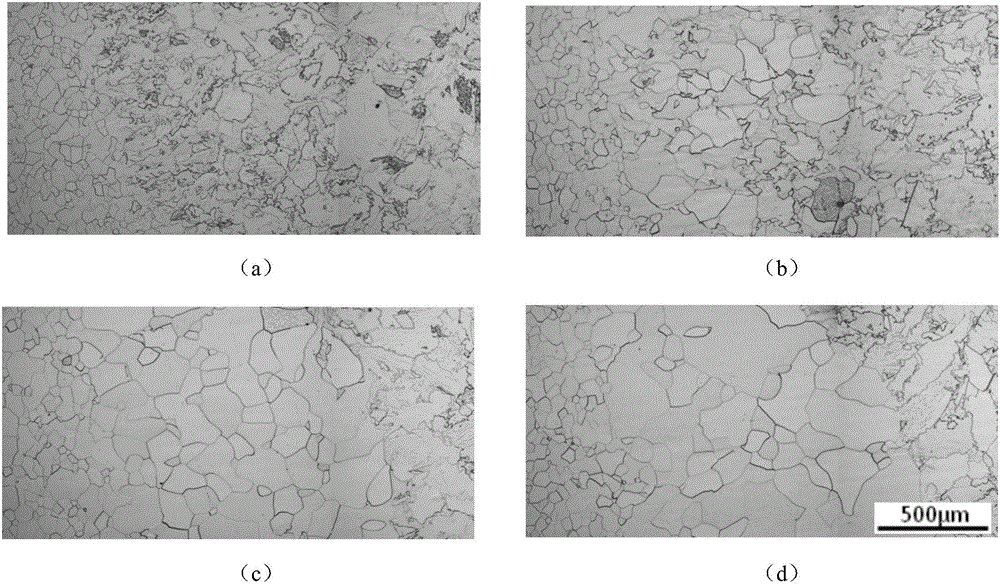

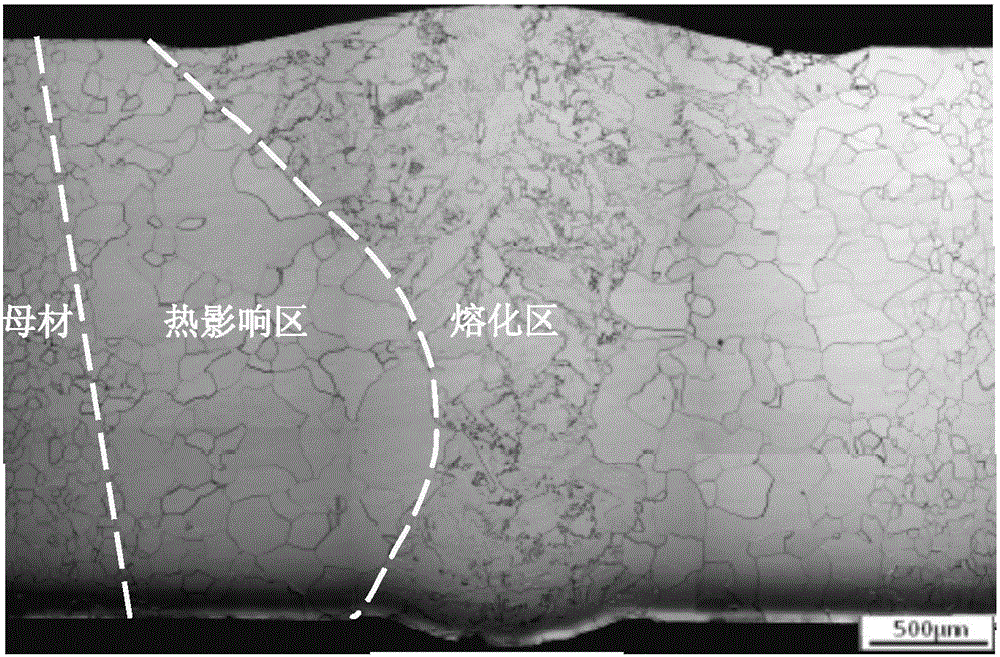

[0020] (1) Method principle

[0021] For industrial pure titanium fusion welded joint samples, the metallographic observation of the cross-section is carried out first. Due to the difference in the structure of the base metal and the heat-affected zone, the two can be easily distinguished. However, since the occurrence of phase transformation conceals the solidification characteristics of the melting zone, the microstructures of the heat-affected zone and the melting zone are similar in metallographic observation, and their boundaries are difficult to distinguish. In the present invention, the sample (industrial pure titanium fusion welding joint) is fully heat-treated, and it is found that the grain boundaries in the heat-affected zone are flattened, and the grains transform to equiaxed; while the microstructure of the base metal and the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com