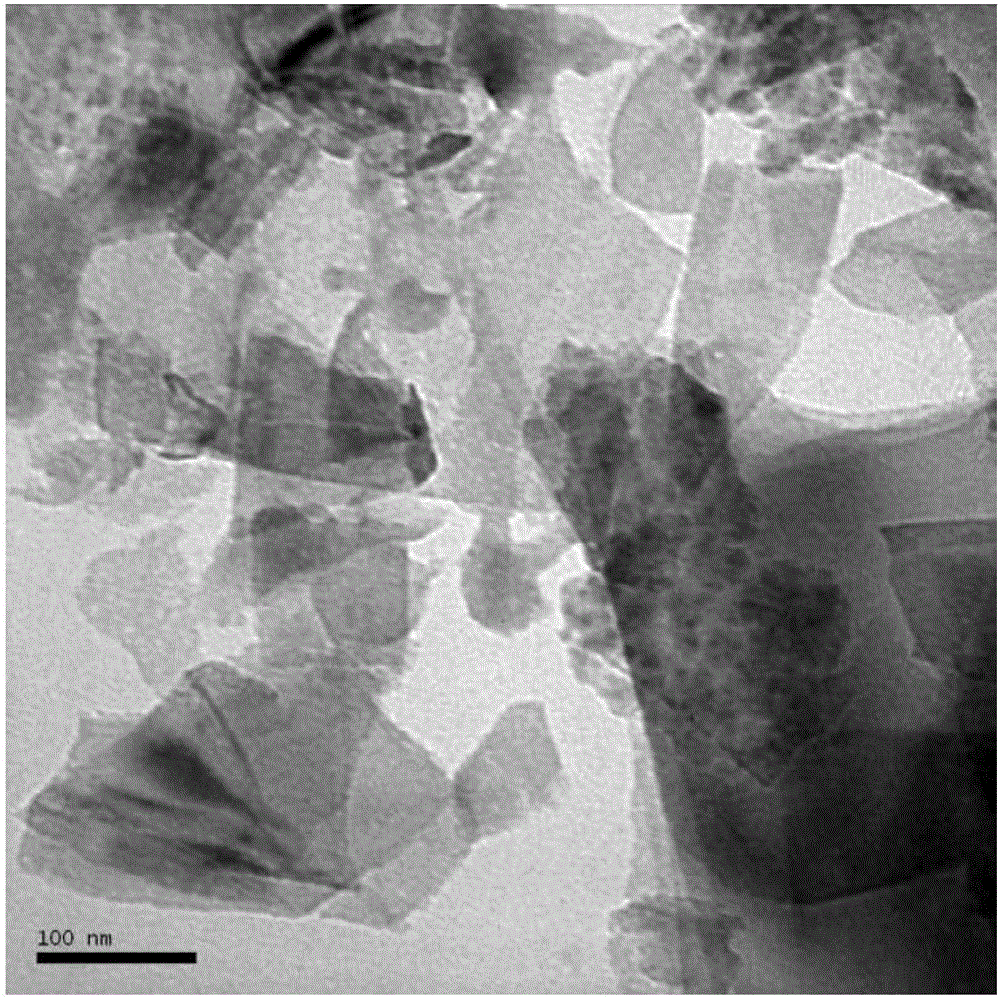

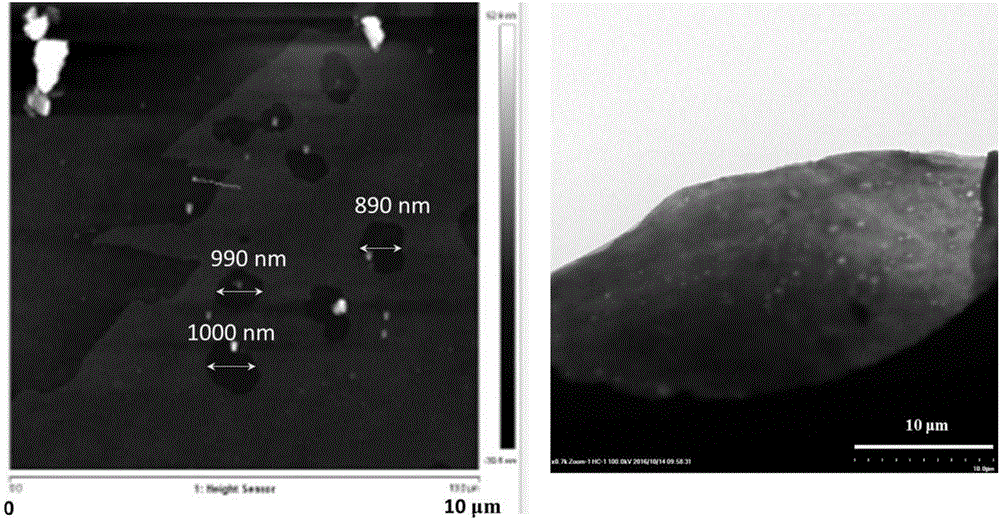

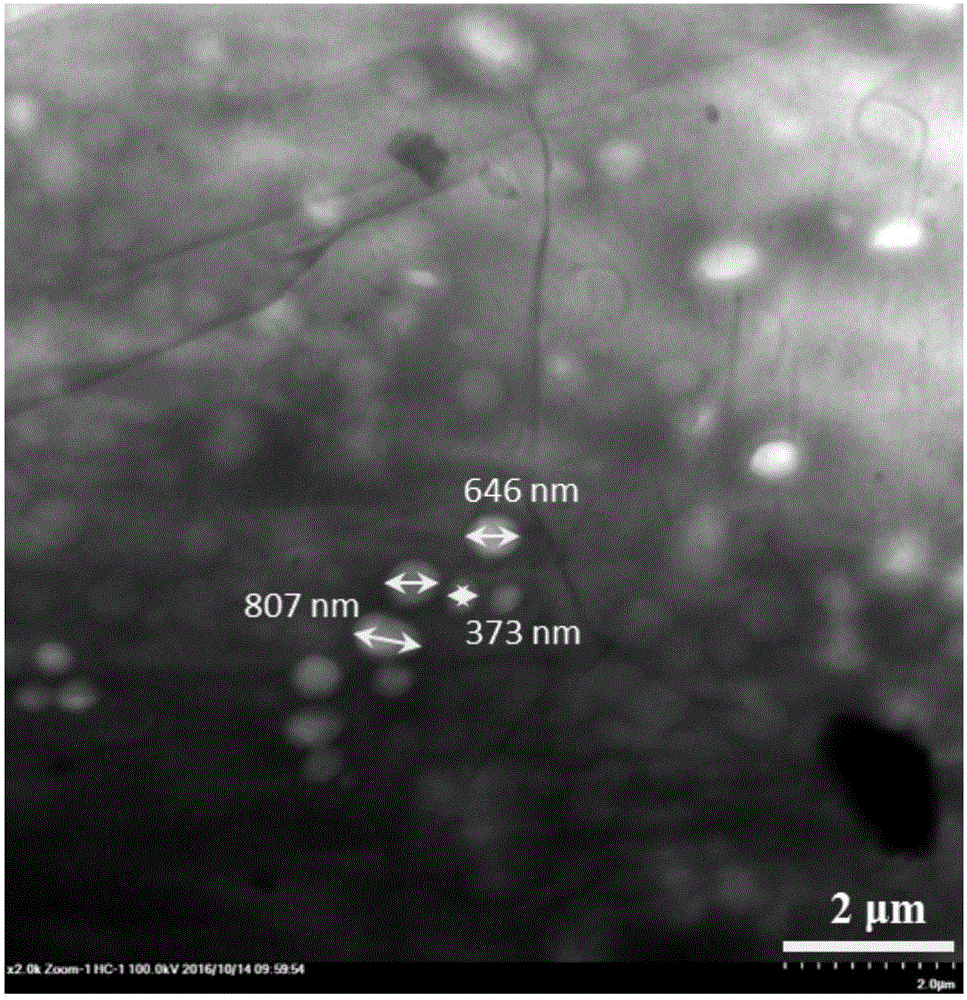

Two-dimensional lamellar porous black phosphorus material and preparation method thereof

A two-dimensional layered, black phosphorus technology, used in phosphorus preparation, nanotechnology for materials and surface science, bulk chemical production, etc. problem, to achieve the effect of high yield, low cost and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of a two-dimensional layered porous black phosphorus material, comprising the following steps:

[0055] Step (1). Di(butyl)methylsulfonium hexafluorophosphate was vacuum-dried at 100°C for 48h;

[0056] Step (2). 10mg block black phosphorus, dried bis(butyl) methylsulfonium hexafluorophosphate 5mg, join in the N-methylpyrrolidone of 40mL by mass ratio in the weight ratio of 100:50 ( NMP), in which the concentration of massive black phosphorus in N-methylpyrrolidone is 0.25mg / mL, and the probe is ultrasonicated for 3 hours with a power of 900W under the sealed condition, and the temperature is controlled at 5°C during the whole process of probe ultrasonication ; Then perform ultrasonication in a water bath with a power of 500W for 3h, and control the temperature at 5°C during the entire process of ultrasonication in a water bath. After standing still overnight, the supernatant was centrifuged at 7000rpm for 10min to collect the precipitate to obtain...

Embodiment 2

[0058] A preparation method of a two-dimensional layered porous black phosphorus material, comprising the following steps:

[0059] Step (1). Di(butyl)methylsulfonium hexafluorophosphate was vacuum-dried at 100°C for 48h;

[0060] Step (2). 10mg block black phosphorus, dried bis(butyl) methylsulfonium hexafluorophosphate 50mg, join in the N-methylpyrrolidone of 2mL by mass ratio in the weight ratio of 100:500 ( NMP), wherein the concentration of massive black phosphorus in N-methylpyrrolidone is 5 mg / mL, and the probe is ultrasonicated for 3 hours with a power of 900 W under sealed conditions, and the temperature is controlled at 5 °C during the entire probe ultrasonic process. ; Then perform ultrasonication in a water bath with a power of 500W for 3h, and control the temperature at 5°C during the entire process of ultrasonication in a water bath. After standing still overnight, the supernatant was centrifuged at 7000rpm for 10min to collect the precipitate to obtain a two-di...

Embodiment 3

[0062] A preparation method of a two-dimensional layered porous black phosphorus material, comprising the following steps:

[0063] Step (1). Di(butyl)methylsulfonium hexafluorophosphate was vacuum-dried at 100°C for 48h;

[0064] Step (2). Add 10mg block black phosphorus and 75mg of dried bis(butyl)methylsulfonium hexafluorophosphate into 0.2mL of N-methylpyrrolidone in a weight ratio of 100:750 by mass (NMP), wherein the concentration of massive black phosphorus in N-methylpyrrolidone is 50 mg / mL, and the probe is ultrasonicated for 3 h with a power of 900 W under a sealed condition, and the temperature is controlled at 5 during the entire probe ultrasonic process. °C; then conduct ultrasonication in a water bath with a power of 500W for 3h, and control the temperature at 5 °C during the entire process of ultrasonication in a water bath. After standing still overnight, the supernatant was centrifuged at 7000rpm for 10min to collect the precipitate to obtain a two-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com