Observation elevator heat-insulating glass and preparation method thereof

A technology for insulating glass and sightseeing elevator, applied in the field of sightseeing elevator materials, can solve the problems of short service life and poor performance of sightseeing elevator glass, and achieve the effects of good acid and alkali corrosion resistance, good safety and high weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

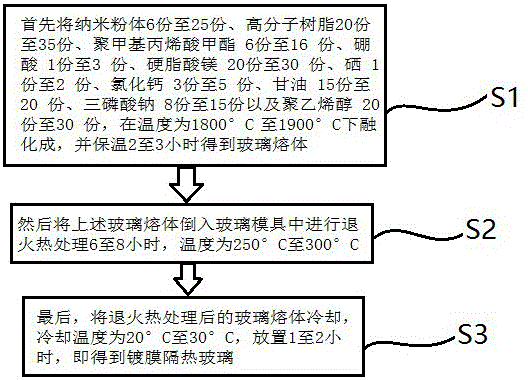

[0023] The invention provides a coated heat-insulating glass for a sightseeing elevator, which mainly includes raw materials: 6kg to 25kg of nano powder, 20kg to 35kg of polymer resin, 6kg to 16kg of polymethyl methacrylate, 1kg to 3 kg of boric acid, stearin 20kg to 30kg of magnesium oxide, 1kg to 2kg of selenium, 3kg to 5kg of calcium chloride, 15kg to 20kg of glycerin, 8kg to 15kg of sodium triphosphate and 20kg to 30kg of polyvinyl alcohol; Insulating glass has good heat insulation performance, can largely isolate the temperature between the interior and exterior of the elevator, and is not easily affected by external factors when the elevator is on a high floor, thereby improving the exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com