Preparation method of (Bi<0.5>Na<0.5>)<1-x>SrxTiO3 system-based lead-free relaxor ferroelectrics

A ferroelectric and system technology, which is applied in the field of preparation of lead-free relaxor ferroelectrics of 1-xSrxTiO3 system, can solve problems such as restricting use performance, and achieve the effects of good relaxation characteristics, improved dielectric constant and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

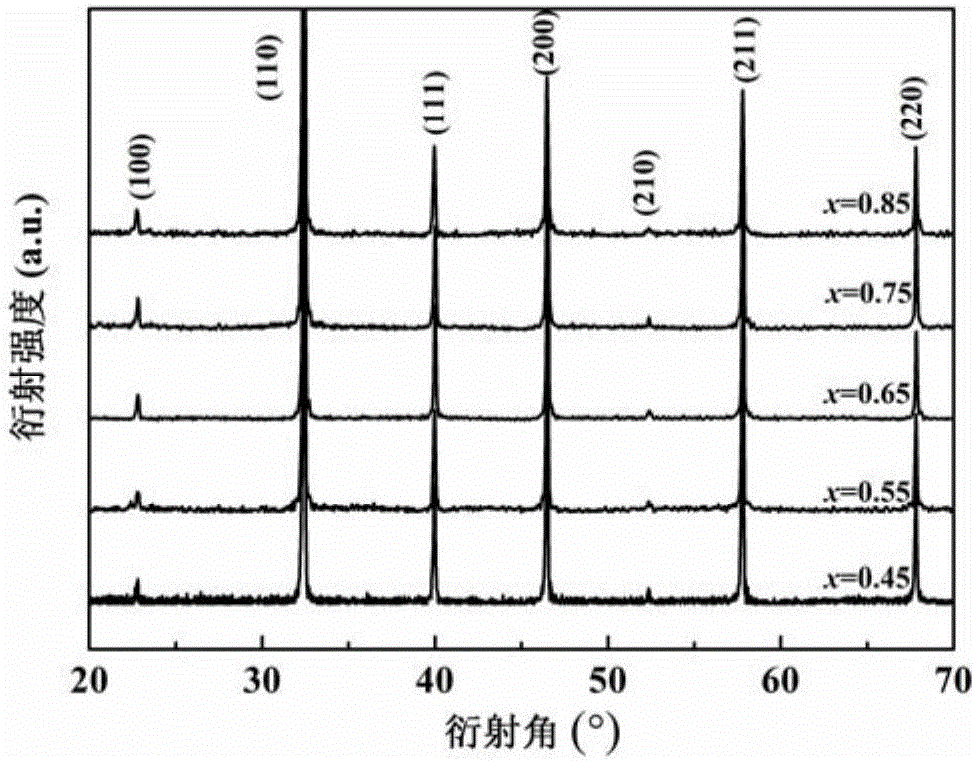

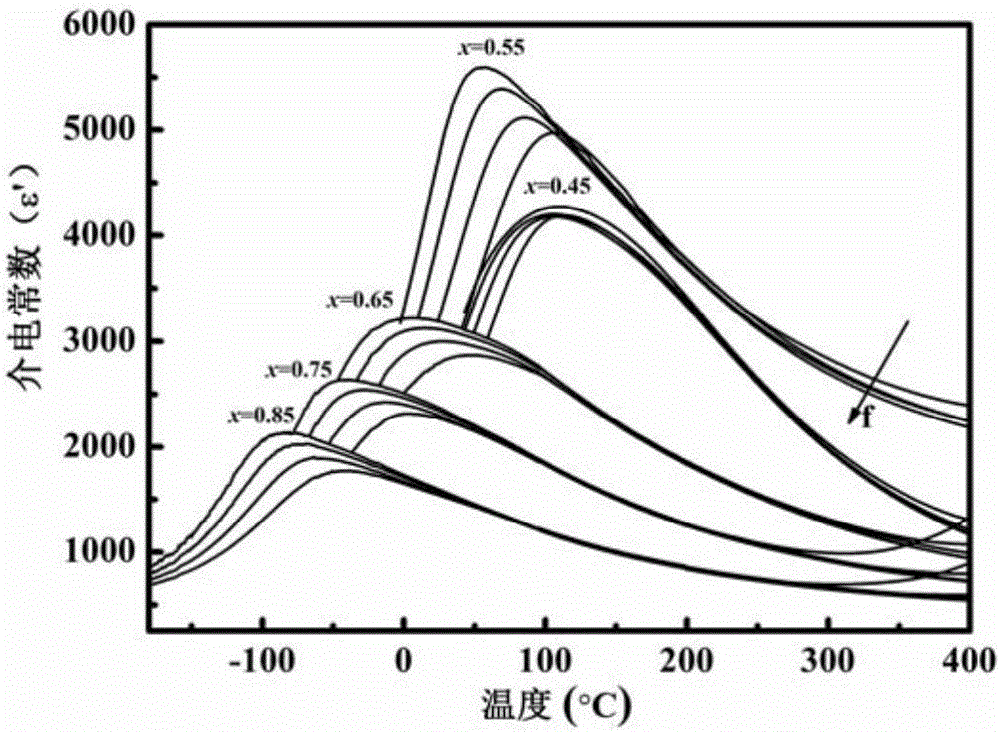

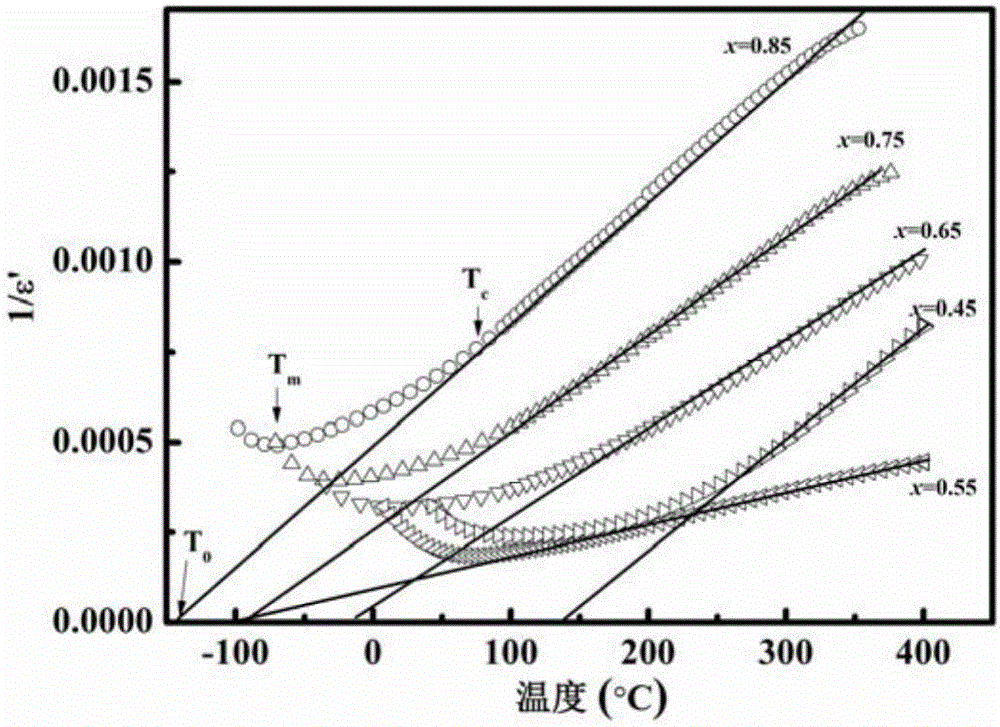

[0033] A new type (Bi 0.5 Na 0.5 ) 1-x Sr x TiO 3 The preparation method of the lead-free relaxation ferroelectric system comprises the following steps:

[0034] Step 1: (Bi 0.5 Na 0.5 ) 1-x Sr x TiO 3 System ceramics (x=0.45, 0.55, 0.65, 0.75, 0.85),

[0035] a. When x=0.45, Na 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The molar ratio is 11:11:9:53;

[0036] b. When x=0.55, Na 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The molar ratio is 9:9:11:47;

[0037] c. When x=0.65, Na 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The molar ratio is 7:7:13:41;

[0038] d. When x=0.75, Na 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The molar ratio is 1:1:3:7;

[0039] e. When x=0.85, Na 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The molar ratio is 3:3:17:29;

[0040] Weigh the corresponding mass of Na according to the above molar ratio 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The mixture is obtained, and the mixture is mixed with zirconia ball stones and deionized water according to the mass ...

Embodiment 1

[0047] The present invention (Bi 0.5 Na 0.5 ) 1-x Sr x TiO 3 System lead-free relaxor ferroelectric, its formulation is (Bi 0.5 Na 0.5 ) 1- x Sr x TiO 3 , where x=0.45, where x is a mole percent.

[0048] Step 1: Weigh the corresponding mass of Na according to the molar ratio 11:11:9:53 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The mixture is obtained, and the mixture is mixed with zirconia ball stones and deionized water according to the mass ratio of 1:2:1, and then ball milled and dried to obtain a dried material;

[0049] Step 2: After briquetting the dried material, place it in a muffle furnace at 840°C for 3 hours to form a complete batch;

[0050] Step 3: Carry out granulation and sieve successively with the full batching that step 2 obtains, the process of forming granulated material is: the mass concentration of polyvinyl alcohol in binder (polyvinyl alcohol aqueous solution, in polyvinyl alcohol aqueous solution is 4% ) is added to the whole ingredients for ...

Embodiment 2

[0054] The present invention (Bi 0.5Na 0.5 ) 1-x Sr x TiO 3 System lead-free relaxor ferroelectric, its formula is (Bi 0.5 Na 0.5 ) 1- x Sr x TiO 3 , where x=0.55, where x is a mole percent.

[0055] Step 1: Weigh the corresponding mass of Na according to the molar ratio 9:9:11:47 2 CO 3 、 Bi 2 o 3 , SrCO 3 、TiO 2 The mixture is obtained, and the mixture is mixed with zirconia ball stones and deionized water according to the mass ratio of 1:2:1, and then ball milled and dried to obtain a dried material;

[0056] Step 2: After briquetting the dried material, place it in a muffle furnace at 850°C for 3 hours to form a complete batch;

[0057] Step 3: Carry out granulation and sieve successively with the full batching that step 2 obtains, the process of forming granulated material is: the mass concentration of polyvinyl alcohol in binder (polyvinyl alcohol aqueous solution, polyvinyl alcohol aqueous solution is 5% ) is added to the whole batching for granulation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com