Low-shrinkage UV curing PUA resin, as well as preparation method and application thereof to preparation of hot bending membrane

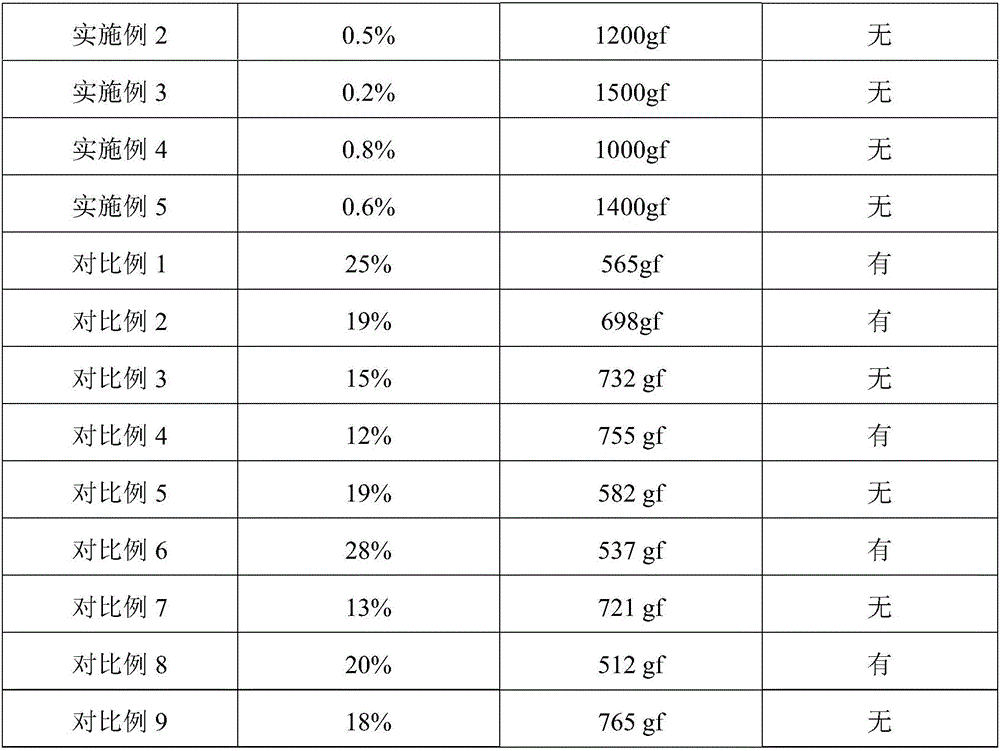

A technology of resin and reaction, applied in low-shrinkage UV-cured PUA resin and its preparation, and the application field of hot bending film preparation, can solve the requirements of low shrinkage rate, can not meet the problems of hot bending film, low shrinkage rate, etc., and achieve Effects of low shrinkage, low curing shrinkage, and high shear tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

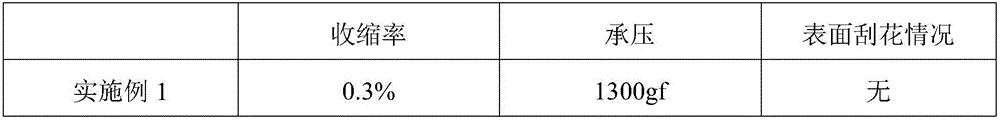

Embodiment 1

[0038] In this embodiment, the UV curing PUA resin is prepared by the following method, which specifically includes the following steps:

[0039] (1) Diisocyanate, polyol and chain extender are reacted at 80° C. for 5 hours in the presence of a catalyst to obtain polyurethane;

[0040] (2) adding hydroxyethyl acrylate to the reaction system obtained in step (1), and reacting at 80°C for 3 hours to obtain the UV curable PUA resin;

[0041] Wherein the mol ratio of polyol and diisocyanate is 30:1, and described polyol is the mixture of polyester polyol and polyether polyol, and the mol ratio of polyester polyol and polyether polyol in the described mixture is 5:1; the functionality of polyester polyol and polyether polyol is 6, the number average molecular weight of polyol is 1000, and described diisocyanate is toluene diisocyanate and diphenylmethane diisocyanate of molar ratio 1:1 The combination, the chain extender is ethylene glycol, the catalyst is stannous octoate, the mo...

Embodiment 2

[0044] In this embodiment, the UV curing PUA resin is prepared by the following method, which specifically includes the following steps:

[0045] (1) Diisocyanate, polyol and chain extender are reacted at 60° C. for 8 hours in the presence of a catalyst to obtain polyurethane;

[0046] (2) adding hydroxyethyl acrylate to the reaction system obtained in step (1), and reacting at 60°C for 2 hours to obtain the UV curable PUA resin;

[0047] Wherein the mol ratio of polyol and diisocyanate is 20:1, and described polyol is the mixture of polyester polyol and polyether polyol, and the mol ratio of polyester polyol and polyether polyol in the described mixture is 3:1. The functionality of polyester polyol and polyether polyol is 8, and the number average molecular weight of polyol is 800, and described diisocyanate is the combination of toluene diisocyanate and diphenylmethane diisocyanate of molar ratio 1:2, expands The chain agent is ethylene glycol, the catalyst is stannous oct...

Embodiment 3

[0050] In this embodiment, the UV curing PUA resin is prepared by the following method, which specifically includes the following steps:

[0051] (1) Diisocyanate, polyol and chain extender are reacted at 90° C. for 4 hours in the presence of a catalyst to obtain polyurethane;

[0052] (2) adding hydroxyethyl acrylate to the reaction system obtained in step (1), and reacting at 90°C for 3 hours to obtain the UV curable PUA resin;

[0053] Wherein the mol ratio of polyol and diisocyanate is 25:1, and described polyol is the mixture of polyester polyol and polyether polyol, and the mol ratio of polyester polyol and polyether polyol in the described mixture is 4:1, the functionality of polyester polyol and polyether polyol is 10, the number average molecular weight of polyol is 1500, and described diisocyanate is toluene diisocyanate and diphenylmethane diisocyanate of molar ratio 2:1 The combination, the chain extender is 1,3-propanediol, the catalyst is dibutyltin dioctoate, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com