Anti-electrostatic dust sticking mat and preparation method thereof

An anti-static and dust-sticking technology, applied in the direction of adhesives, cleaning equipment, adhesive types, etc., can solve the problems of incomplete dust removal effect and inconvenient operation of sticky dust pads, and achieve excellent anti-static effect, excellent dust removal effect, and production The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

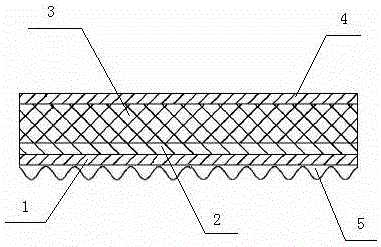

[0039] Specific Embodiments 1. An antistatic dust sticky mat according to this embodiment includes a stacked substrate 1, an adhesive layer 2, an antistatic dust sticky layer 3 and a protective film layer 4 from bottom to top;

[0040] The bottom of the substrate 1 is provided with a number of regularly distributed anti-slip protrusions 5;

[0041] The adhesive layer 2 is made of epoxy resin adhesive;

[0042] Wherein the epoxy resin adhesive is made of 90 to 110 parts of epoxy resin, 5 to 20 parts of carboxylated nitrile latex and 2 to 6 parts of polyacrylate latex in parts by mass; and the carboxylated nitrile The mass ratio of latex and polyacrylate latex is 3:1;

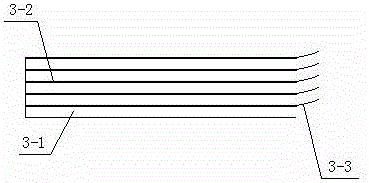

[0043] The antistatic sticky dust layer 3 includes alternately arranged antistatic adhesive film layers 3-1 and adhesive layers 3-2, and one end of the adhesive layer 3-2 is provided with a non-adhesive hinge 3-3;

[0044] The antistatic adhesive film layer 3-1 is composed of an adhesive film coated with an ant...

specific Embodiment approach 2

[0066] Embodiment 2: This embodiment differs from Embodiment 1 in that: the surface of the antistatic adhesive film layer 3-1 is set in a concave-convex shape. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0067] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the number of layers of the antistatic adhesive film layer 3-1 is 40-50. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com