Anti-seismic building structure provided with steel frame and crossed central support with link beams

A technology of building structure and central support, which is applied in the direction of building components, building structure, construction, etc., can solve the problems of residential apartment characteristics mismatch, large wood consumption, unfavorable promotion and utilization, etc., and achieve the goal of improving the level of construction technology and engineering quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below.

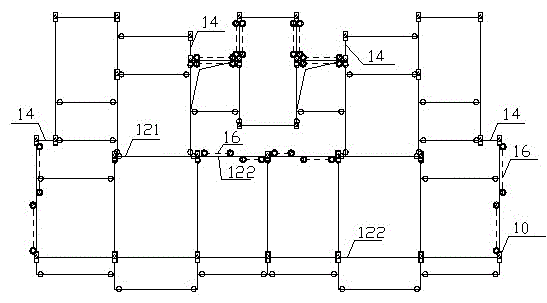

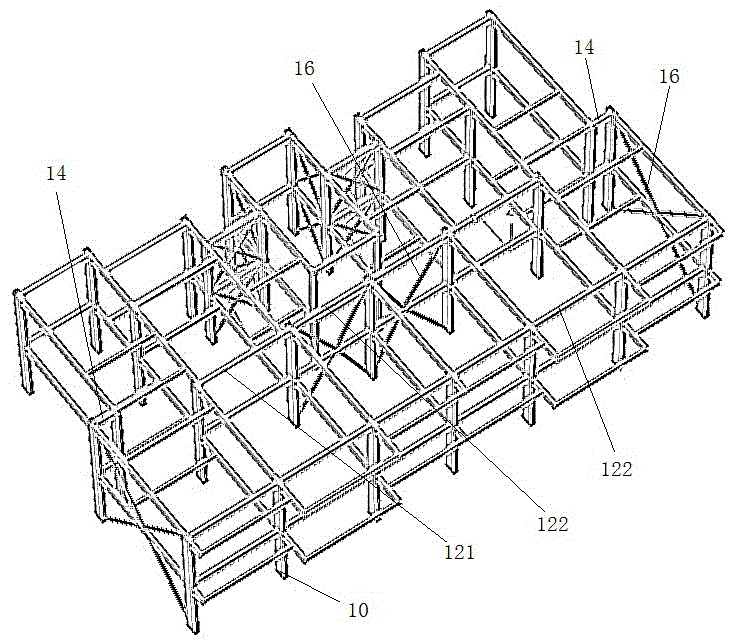

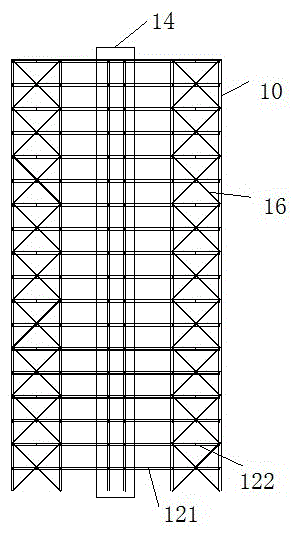

[0020] Such as Figure 1 to Figure 3 As shown, the steel frame with energy-dissipating beams of the present invention and the anti-seismic building structure of cross-shaped central support include rectangular steel tube concrete columns 10, steel beams (including hinged steel beams 121 and rigidly connected steel beams 122), energy-dissipating beams 14, Components such as support bar 16 constitute the double lateral force resistance structure of support and steel frame. For the entire structure, the support rod 16 is the first line of defense, yielding first; the energy dissipation beam 14 is the second line of defense, and then yields after the support rod 16 yields; the steel beam is the third line of defense; the rectangular steel tube concrete column 10 is the last A line of defense, the 4th line of defense. The purpose of the steel frame structure of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com