No-drive LED reflector lamp

A technology of LED lamps and reflector lamps, which is applied in the direction of reflectors, refractors, lighting and heating equipment, etc., can solve the problems of visual impairment of users, complex structure of LED lamps, poor insulation performance, etc. Improve light efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

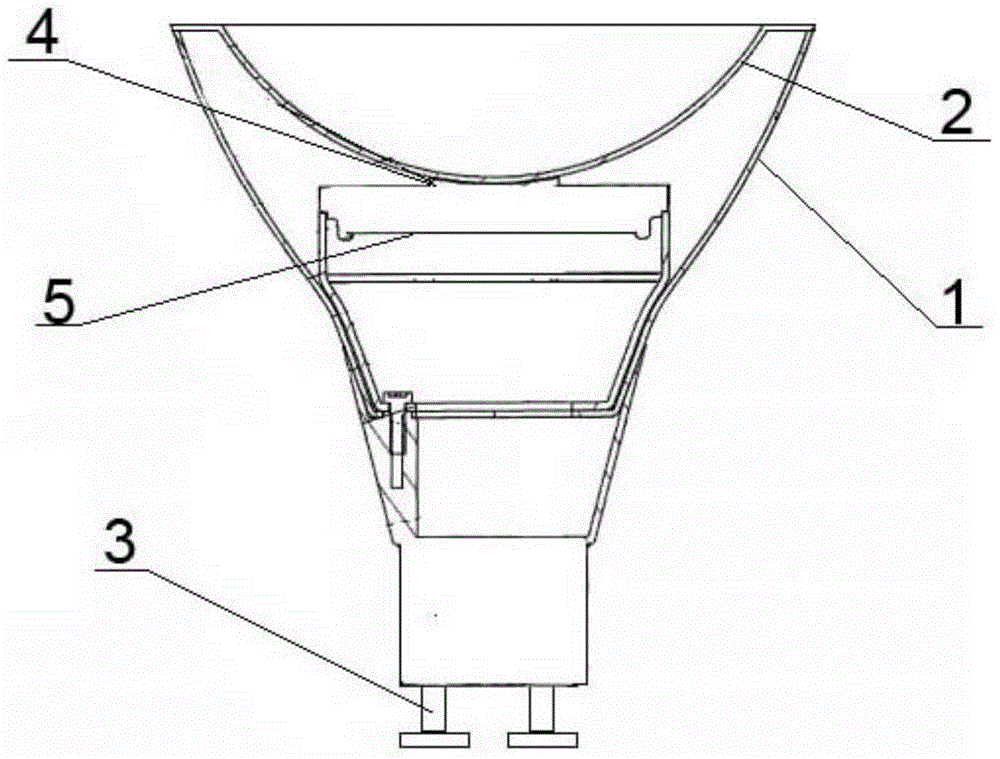

[0012] Such as figure 1 Shown: a non-driven LED reflector lamp, including a cup-shaped lamp body 1 made of glass, a lamp cap 3 screwed to the tail end of the lamp body 1, and an AC LED lamp 4. The outer surface of the glass lampshade 2 is a spherical surface, and the LED reflector The lamp base 3 of the lamp can adopt GU10, GU5.3, E14, E27, E26 or B22, the interior of the lamp body 1 is provided with a light-emitting lens 2, and the inner wall of the lamp body 1 is provided with a lens for reflecting the light of the LED lamp 4 to the front The front reflective layer, the LED lamp 4 is welded on the aluminum substrate, the pins of the LED lamp 4 are electrically connected to the output terminal of the non-power LED driver chip welded on the aluminum substrate 5, and the input terminal of the non-power LED driver chip is connected to the lamp holder The connecting terminals of 3 correspond to the electrical connection, and an electrolytic capacitor is welded on the aluminum sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com