Integrated management and control system for PE pipe welding data

A management and control system and data management technology, applied in the database field, can solve the problem of inconclusive quality and long-term work performance, and achieve the effect of strengthening scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

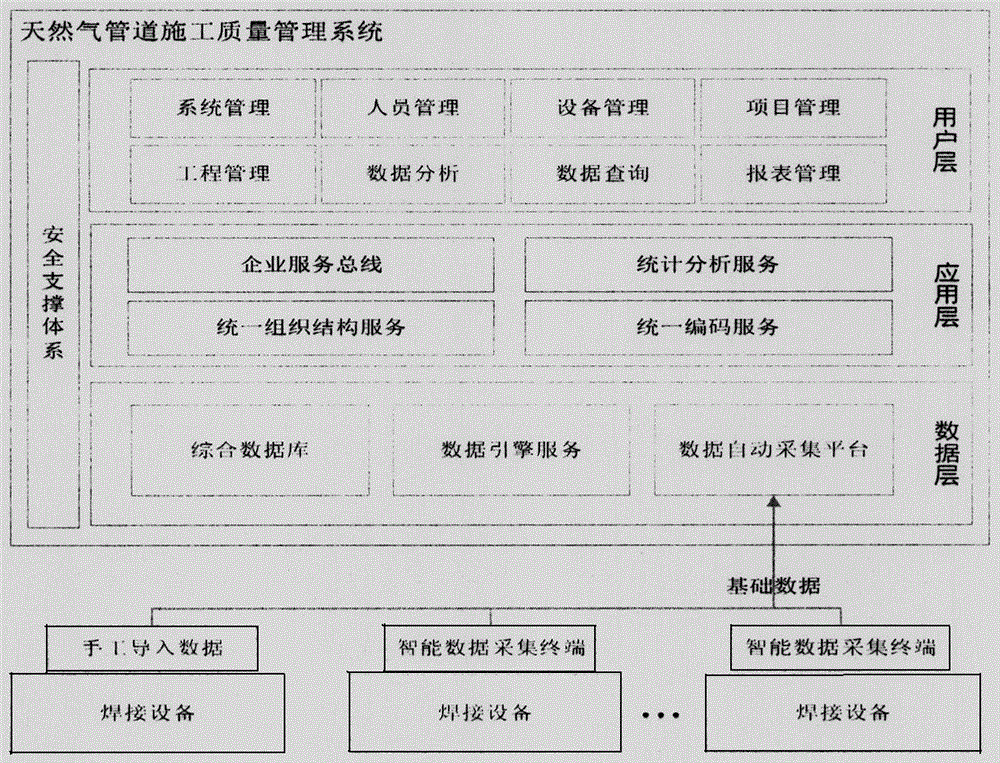

[0030] 1. A comprehensive management and control system for PE pipe welding data, characterized in that it includes a data management terminal and an intelligent data acquisition terminal;

[0031] The data management terminal is set on each user computer, and the data management terminal is divided into user layer, application layer and data layer from top to bottom, and interacts with the adjacent upper and lower layers through a unified service interface;

[0032] The intelligent data acquisition terminal is installed on each welding equipment, used to collect welding data from the welding equipment, and communicate with the automatic data acquisition platform to complete two-way data exchange

[0033] The data layer includes comprehensive database, data engine service module and automatic data collection platform;

[0034] The automatic data collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com