Positive electrode for lithium-ion secondary cell, and lithium-ion secondary cell

A secondary battery, lithium ion technology, used in secondary batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of low internal resistance, unclear density of active material layers, and difficulty in making high capacity, and achieve internal The effect of low resistance, fast charge and discharge output power, and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0145] (1) Fabrication of electrochemical cells

Embodiment 1

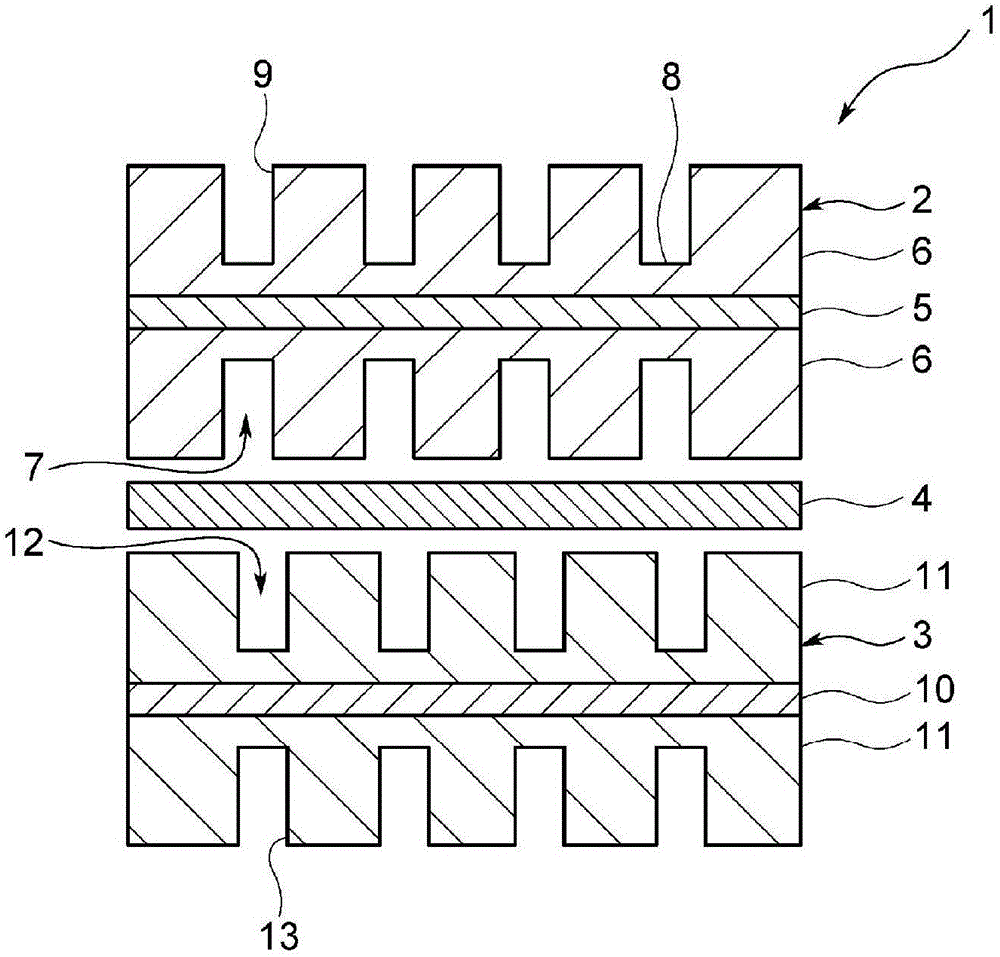

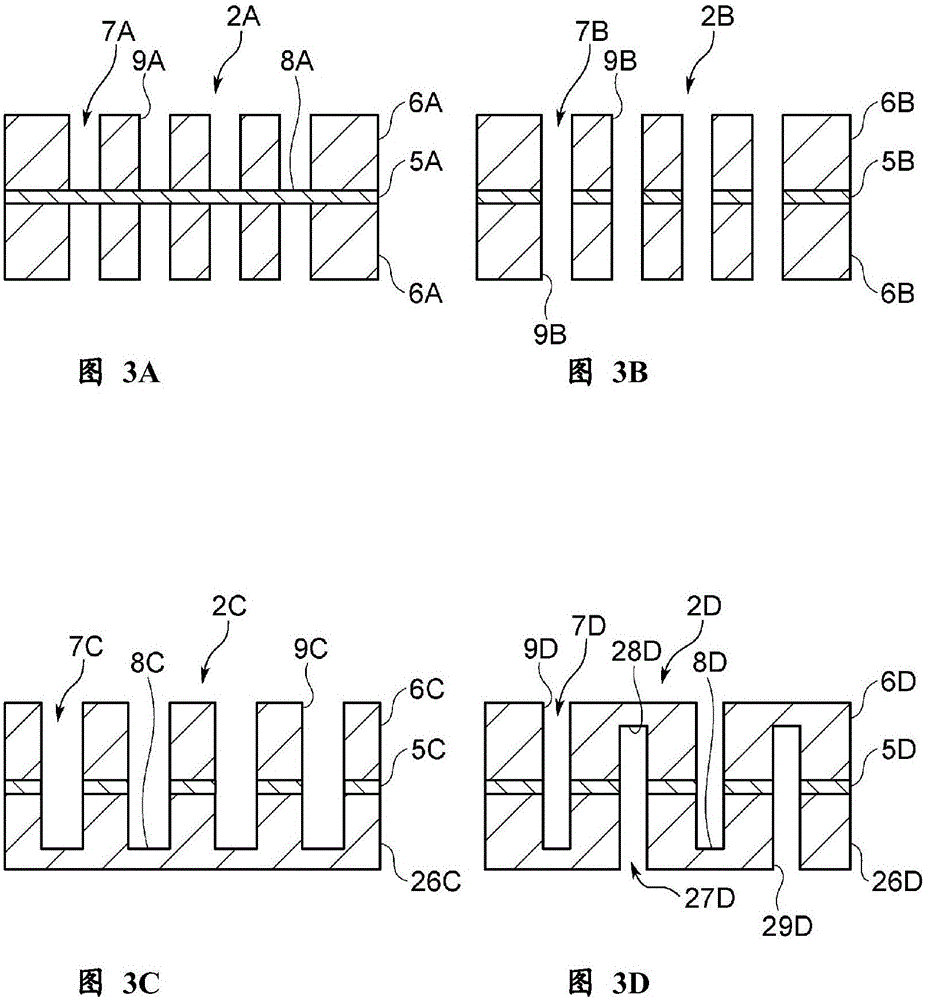

[0146] In Examples 1-6, the positive electrode for lithium ion secondary batteries of this invention using LCO as an active material was produced, and it was applied to the positive electrode of an electrochemical cell. The electrochemical cells of Examples 1 to 6 differ in the depth of the pores formed in the active material layer, but have the same other structures. Therefore, the fabrication method of the electrochemical cells will be described using Example 1 as an example.

[0147] First, LCO as an active material, PVDF as a binder, and AB as a conductive additive were measured in a mass ratio of 95:3:2. Thereafter, the measured amount of PVDF was added to N-methyl-2-pyrrolidone (NMP) as a solvent, and stirred for 20 minutes. Furthermore, LCO and AB were added and stirred to obtain a positive electrode slurry whose viscosity was adjusted to 5 Pa·s.

[0148] Next, prepare an aluminum foil with a thickness of 15 μm cut into a size of 3 cm × 3 cm as a collector, and apply t...

Embodiment 5

[0209] The electrochemical cell of Example 5 has a hole penetrating through the active material layer and forming a bottom with aluminum foil. On the other hand, the electrochemical cell of Example 6 has a through hole penetrating the aluminum foil and the active material layer. In this way, when comparing Example 5 and Example 6, there is a difference between Example 5 and Example 6 whether or not through-holes are formed in the aluminum foil. However, the discharge capacity values of the electrochemical cells of Example 5 and Example 6 were equal. In this way, even if through-holes are formed in the aluminum foil, the performance of the battery will not be degraded.

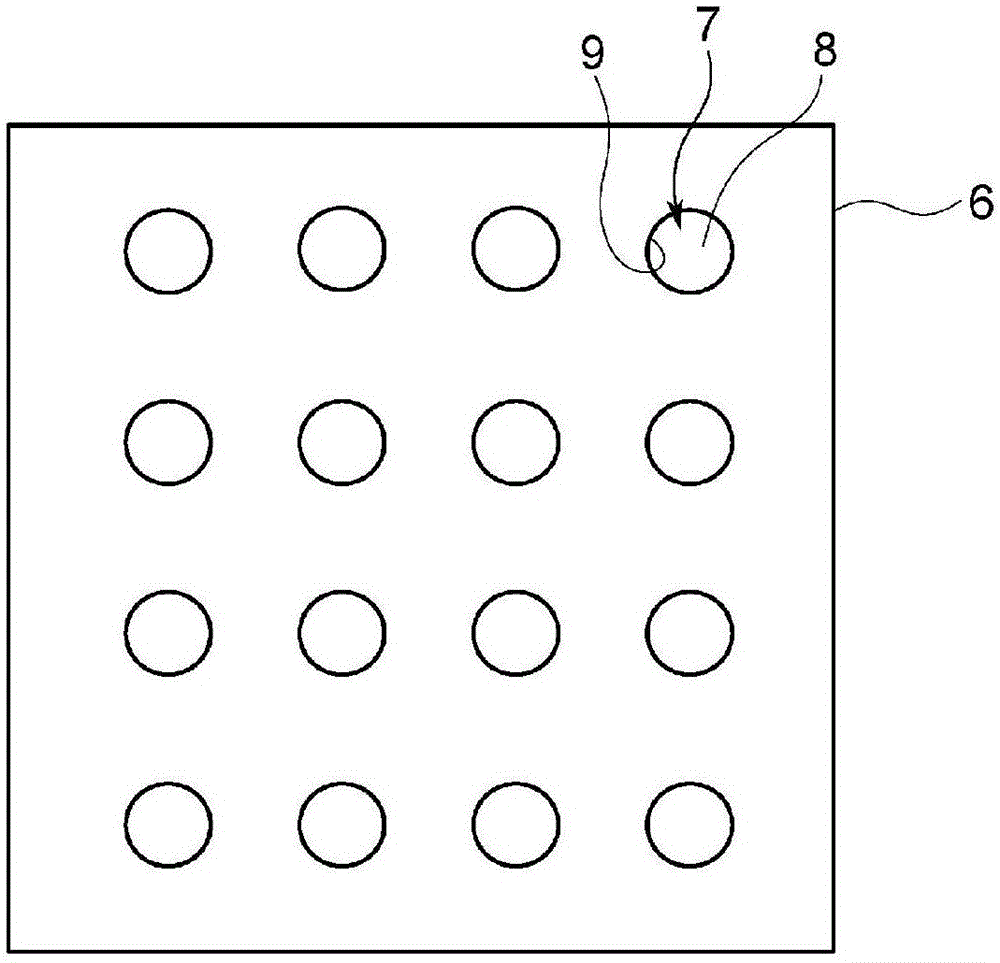

[0210] (3-2) Relationship between the center spacing of the pores of the active material layer and the characteristics of the electrochemical cell

[0211] As shown in Table 2, the embodiment The electrochemical cell, the center interval of the hole is Pores were formed at the positive electrode at inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com