Preparation method of olaparib solid dispersoid and product thereof

A technology of solid dispersion and compound, applied in the field of preparation of olaparib solid dispersion, can solve the problems of low reproducibility, complicated process, residual organic solvent, etc., to achieve continuous large-scale production and simple and easy process , the effect of improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of olaparib solid dispersion and capsules.

[0028] Olaparib (50g) and copovidone VA64 (950g) were passed through a 60-mesh sieve respectively, and the sieved olaparib and copovidone VA64 were mixed uniformly to obtain a mixture of raw and auxiliary materials (1000g).

[0029] Set the extrusion temperature of the twin-screw extruder to 150°C. After reaching the temperature, add the above-mentioned mixture of raw and auxiliary materials into the extruder, melt and extrude, and finally extrude in strips to obtain strips. Extrudate (960 g).

[0030] The strip-shaped extrudate was cooled to room temperature, crushed and passed through a 20-mesh sieve to obtain a granular olaparib solid dispersion (960 g).

[0031] According to the filling amount of 50 mg solid dispersion / particle, the above-mentioned granular olaparib solid dispersion is packed into a hard capsule shell to obtain the corresponding capsule.

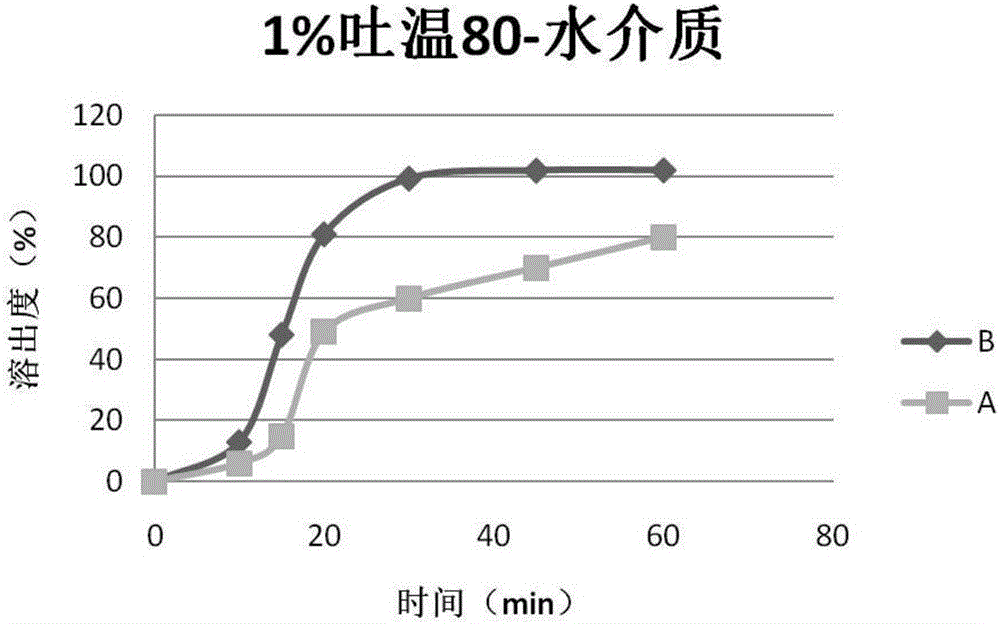

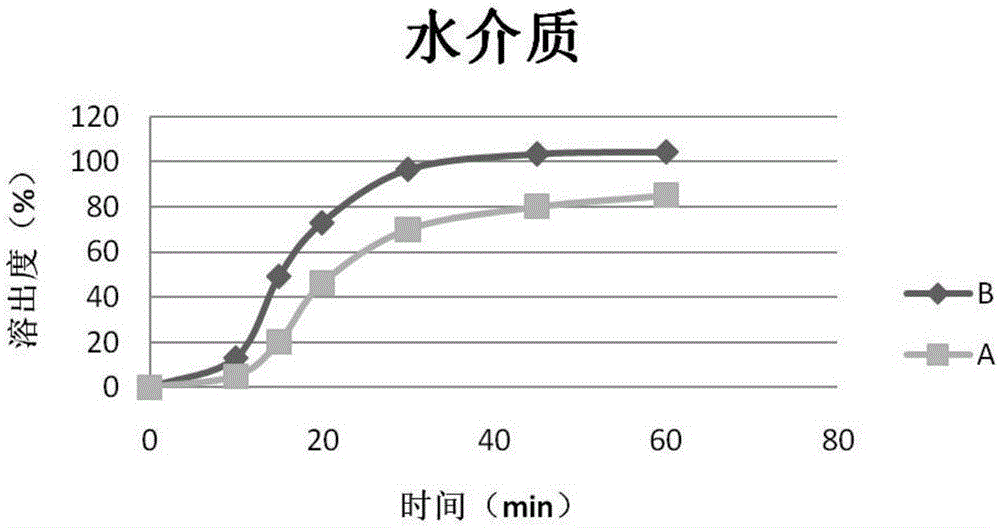

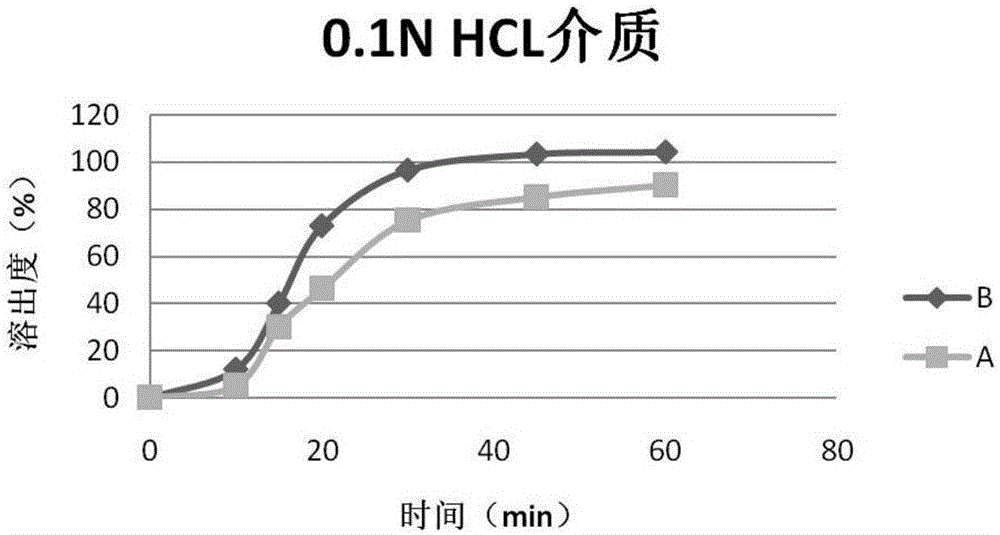

[0032] According to the second method ...

Embodiment 2

[0034] Embodiment 2: Preparation of olaparib solid dispersion and capsules.

[0035] Olaparib (100g) and povidone K30 (900g) were passed through a 70-mesh sieve respectively, and the sieved olaparib and povidone K30 were mixed uniformly to obtain a mixture of raw and auxiliary materials (1000g).

[0036] Set the extrusion temperature of the twin-screw extruder to 180°C. After reaching the temperature, add the above-mentioned mixture of raw and auxiliary materials into the extruder, melt and extrude, and finally extrude in strips to obtain strips. Extrudate (955 g).

[0037] The strip-shaped extrudate was cooled to room temperature, crushed and passed through a 40-mesh sieve to obtain a granular olaparib solid dispersion (945 g).

[0038] According to the filling amount of 50 mg solid dispersion / particle, the above-mentioned granular olaparib solid dispersion is packed into a hard capsule shell to obtain the corresponding capsule.

[0039] According to the second method of ap...

Embodiment 3

[0041] Embodiment 3: Preparation of olaparib solid dispersion and capsules.

[0042] Olaparib (150g) and povidone K30 (850g) were passed through an 80 mesh sieve respectively, and the sieved olaparib and povidone K30 were mixed uniformly to obtain a mixture of raw and auxiliary materials (1000g).

[0043] Set the extrusion temperature of the twin-screw extruder to 200°C. After reaching the temperature, add the above-mentioned mixture of raw and auxiliary materials into the extruder, melt and extrude, and finally extrude in strips to obtain strips. Extrudate (960 g).

[0044] The strip-shaped extrudate was cooled to room temperature, crushed and passed through a 50-mesh sieve to obtain a granular olaparib solid dispersion (940 g).

[0045] According to the filling amount of 50 mg solid dispersion / particle, the above-mentioned granular olaparib solid dispersion is packed into a hard capsule shell to obtain the corresponding capsule.

[0046] According to the second method of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com