Centrifugal rotational flow defomaing type gas-liquid mixture feeding distributor

A feed distributor, swirl defoaming technology, applied in the field of separation towers, can solve the problem of reducing the pressure drop of the feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

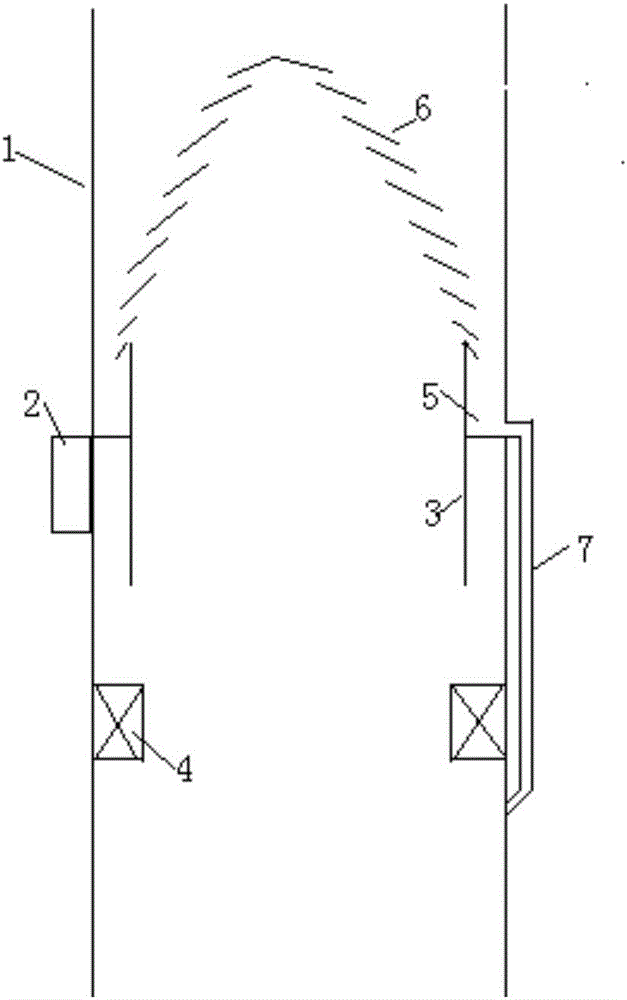

[0022] A centrifugal cyclone defoaming type gas-liquid mixed-phase feed distributor is integrated through the following structure: the gas-liquid mixed-phase feed inlet (2) is a rectangular feeding structure in the tangential direction, and the inner annular sleeve of the tower body (1) (3) are connected; the lower end of the annular sleeve (3) is open, and the distance from the lower end of the annular sleeve (3) is 200-1500mm, and the annular grid filler (4) with the function of guiding deceleration and strengthening the separation of the entrained vapor phase is provided, and the height is 50-100mm , the width is 0.3-2.5 times of the width of the annular sleeve (3), the spacing between the plates of the annular grid packing (4) is 3-50mm, and the horizontal inclination of the packing plate is 30°-90°; the middle part of the annular sleeve (3) Closed to form an annular oil collection tank (5), the outer wall of the bottom of the annular oil collection tank (5) communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com