Dioxin removal system and application of dioxin removal system

A technology for removal and activated carbon, which is applied in the direction of using liquid separation agent, separation method, and separation of dispersed particles, can solve the problems of poor regeneration of dioxins and other problems, achieve high removal rate of dioxins, save costs, and improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

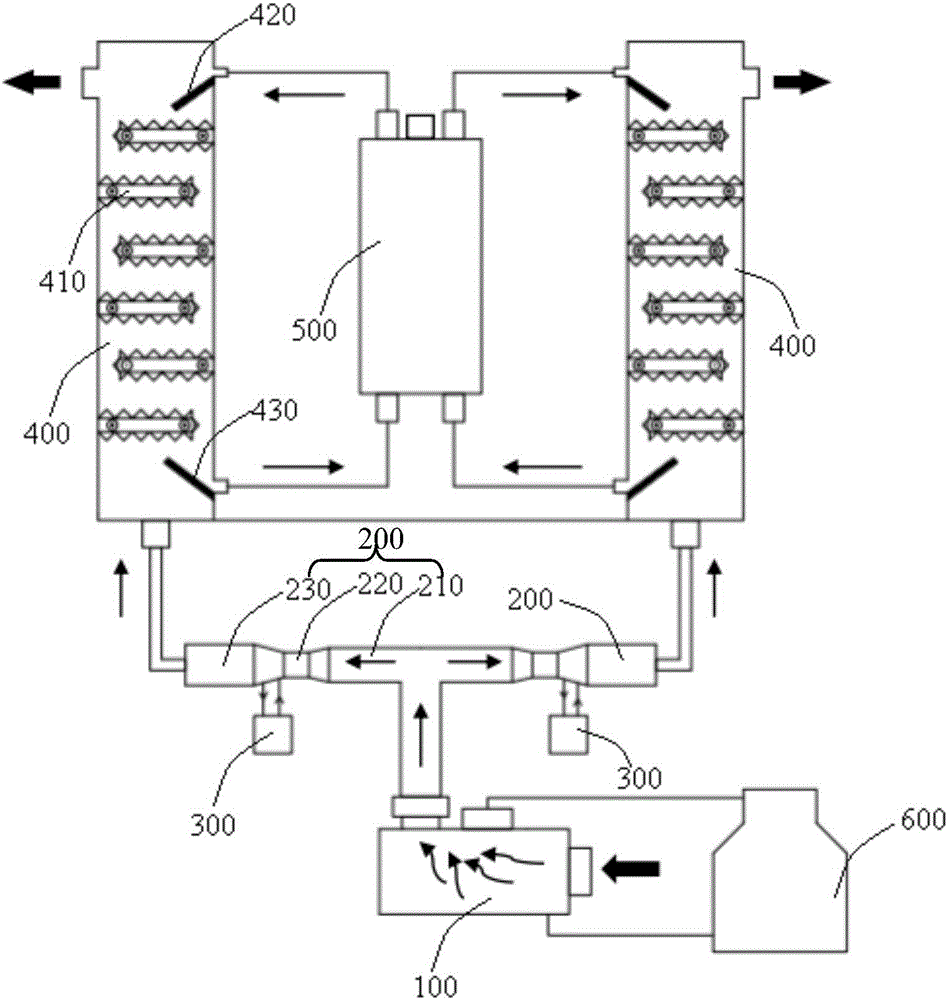

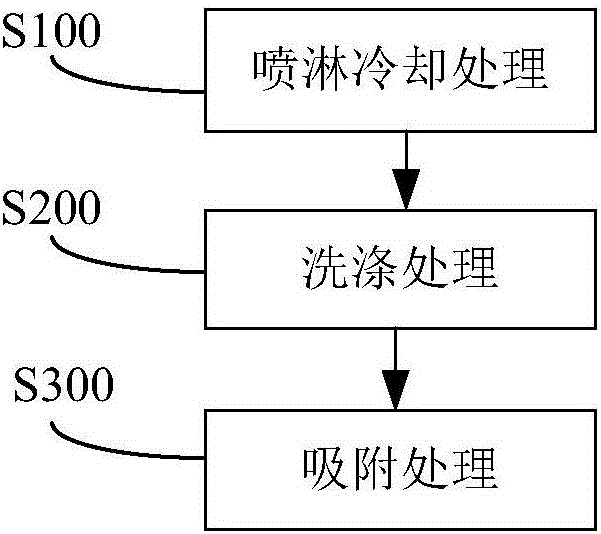

[0059] The dioxin removal system of the embodiment of the present invention is used to treat the waste high-temperature flue gas of a waste incineration treatment plant, wherein the structural diagram of the dioxin removal system is as follows figure 1 As shown, the specific method is as follows:

[0060] (1) Waste flue gas (800-900°C) enters through the flue gas inlet of the quenching tower, and the flue gas is rapidly cooled to 100-200°C by the cooling water sprayer, and the cooling water after heat exchange enters the cooling tower to cool down Return to the chilling tower, so as to realize the recycling of chilling water, and regularly remove the residual liquid accumulated in the chilling tower.

[0061] (2) The chilled low-temperature flue gas enters the parallel Venturi scrubber 200 in two ways, and the flue gas is mixed with the washing liquid in the throat of the Venturi scrubber 200. The scrubber diffuser section is removed. Thus, the removal of particulate impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com