Force Control Grinding Tool for Laser Weld Grinding

A grinding tool and laser technology, applied in manufacturing tools, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of difficult robot trajectory debugging, difficult control of grinding process parameters, and inability of grinding heads to automatically change tools, etc. Achieve the effect of improving the return on investment ratio, reducing the difficulty of debugging and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

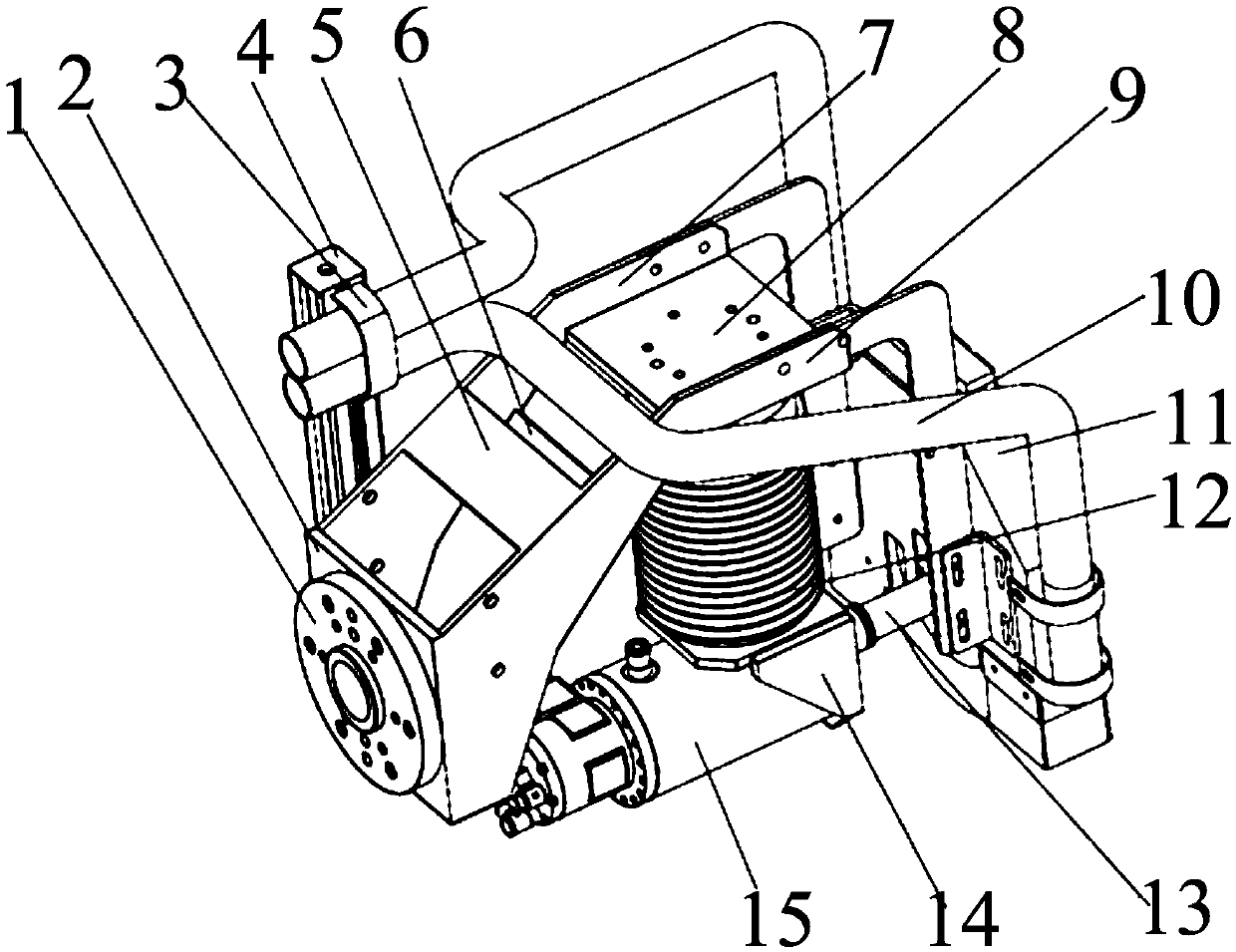

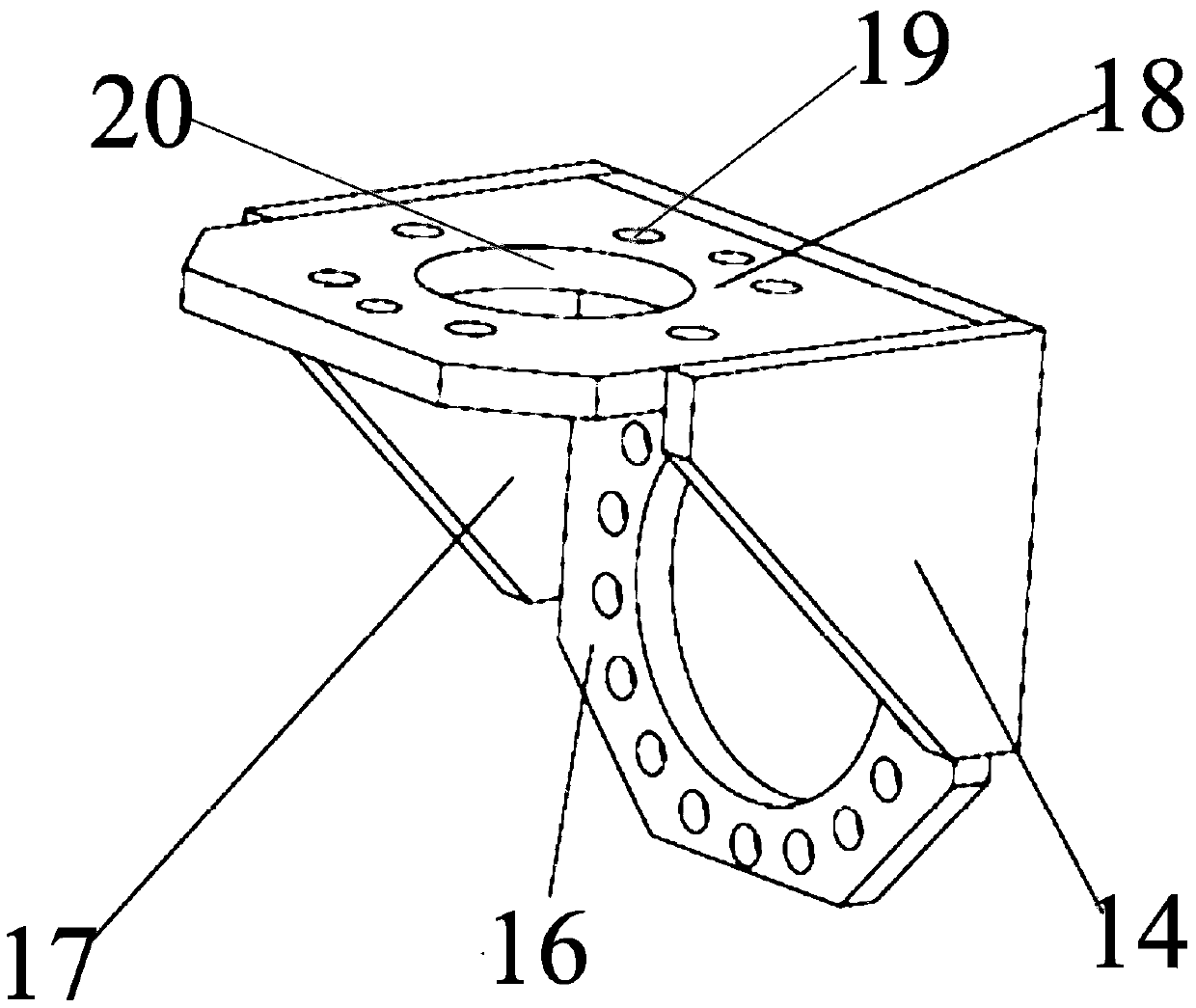

[0018] Such as Figure 1 to Figure 2 As shown, the force-controlled grinding tool for laser weld grinding of the present invention includes an installation assembly, a flexible flange 12, and an electric spindle 15. The installation assembly is to realize the connection between the force-control grinding tool for laser weld grinding and at least one robot. To avoid robot movement interference, the electric spindle is connected vertically with the flexible flange.

[0019] The installation components include the robot connection flange 1, the installation fixed plate 2, the connection snap ring 3, the aluminum profile bracket 4, the upper rib for installing the fixed plate 5, the lower rib for installing the fixed plate 6, and the left connecting plate for installing the fixed plate 7. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com