A kind of yttrium-doped zirconia mesoscopic crystal and its preparation method and application

A technology of zirconia mesoscopic and zirconium oxychloride, which is applied in zirconia, chemical instruments and methods, bulk chemical production, etc., to achieve the effects of rich pores, excellent hydrogen production catalytic performance of water gas shift reaction, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 0.40 g yttrium nitrate, 16.58 g zirconium oxychloride and 6.31 g urea were dissolved in 50mL deionized water, and stirred at room temperature to prepare a mixed solution (the amount of yttrium nitrate accounted for the total amount of yttrium nitrate and zirconium oxychloride 2%), the above mixed solution was calibrated to 70mL with deionized water and then transferred to a high-temperature reaction kettle with a volume of 100mL. Put the reaction kettle into a blast drying oven, control the reaction temperature to 150° C., and the reaction time to 24 hours. The obtained product was washed by centrifugation to remove impurity ions, and then dried at 60° C. for 8 hours to obtain yttrium-doped zirconia mesoscopic crystals.

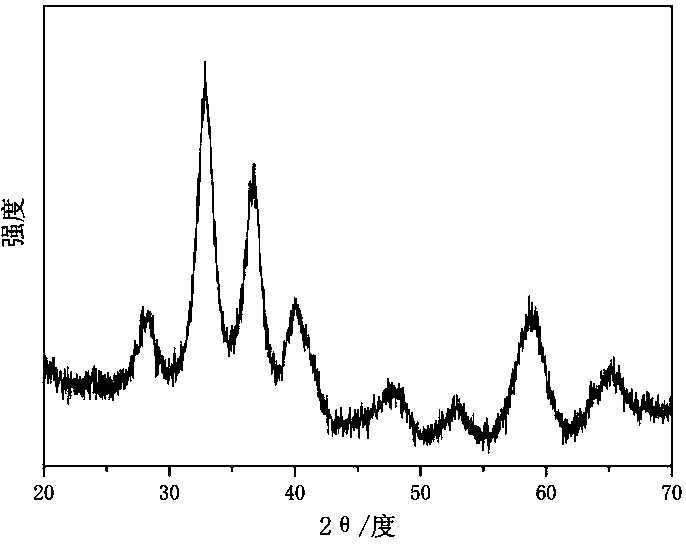

[0025] figure 1 It is the XRD figure of the yttrium-doped zirconia mesoscopic crystal prepared in this embodiment. Depend on figure 1 It can be seen that the prepared yttrium-doped zirconia is in the monoclinic phase.

[0026] figure 2 , image ...

Embodiment 2

[0030] 1.00 g of yttrium nitrate, 16.07 g of zirconium oxychloride and 6.31 g of urea were dissolved in 50 mL of deionized water, and stirred at room temperature to prepare a mixed solution (the amount of yttrium nitrate accounted for the total amount of yttrium nitrate and zirconium oxychloride 5%), the above mixed solution was calibrated to 70mL with deionized water and then transferred to a high-temperature reaction kettle with a volume of 100mL. Put the reaction kettle into a blast drying oven, control the reaction temperature to 150° C., and the reaction time to 24 hours. The obtained product was washed by centrifugation to remove impurity ions, and then dried at 60° C. for 8 hours to obtain yttrium-doped zirconia mesoscopic crystals.

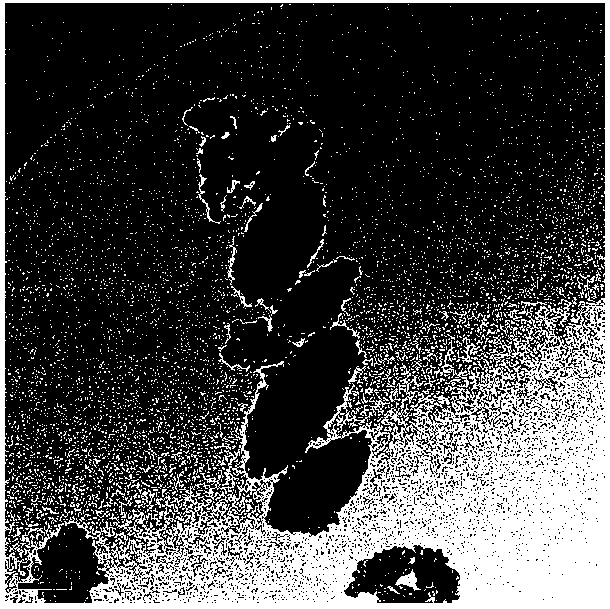

[0031] Figure 5 It is the SEM image of the yttrium-doped zirconia mesoscopic crystal prepared in this embodiment. Figure 5 It shows that the prepared yttrium-doped zirconia particles are also olive-like mesoscopic crystals.

[0032] N...

Embodiment 3

[0034] 2.01 g yttrium nitrate, 15.23 g zirconium oxychloride and 6.31 g urea were dissolved in 50mL deionized water, and after stirring at room temperature, a mixed solution was obtained (the amount of yttrium nitrate accounted for the total amount of yttrium nitrate and zirconium oxychloride 10% of the above), the above mixed solution was calibrated to 70mL with deionized water, and then transferred to a high-temperature reaction kettle with a volume of 100mL. Put the reaction kettle into a blast drying oven, control the reaction temperature to 150° C., and the reaction time to 24 hours. The obtained product was washed by centrifugation to remove impurity ions, and then dried at 60° C. for 8 hours to obtain yttrium-doped zirconia mesoscopic crystals.

[0035] Figure 6 It is the SEM image of the yttrium-doped zirconia mesoscopic crystal prepared in this embodiment. Figure 6 It shows that the prepared yttrium-doped zirconia particles are also olive-like mesoscopic crystals....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com