An adiabatic compressed air energy storage system with non-throttling humidification and enthalpy increase

A compressed air energy storage, non-throttling technology, used in lighting and heating equipment, machines/engines, steam generation, etc. Unstable operating conditions and other problems, to achieve the effect of reducing the cost per unit of power, reducing the volume, and improving the working capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

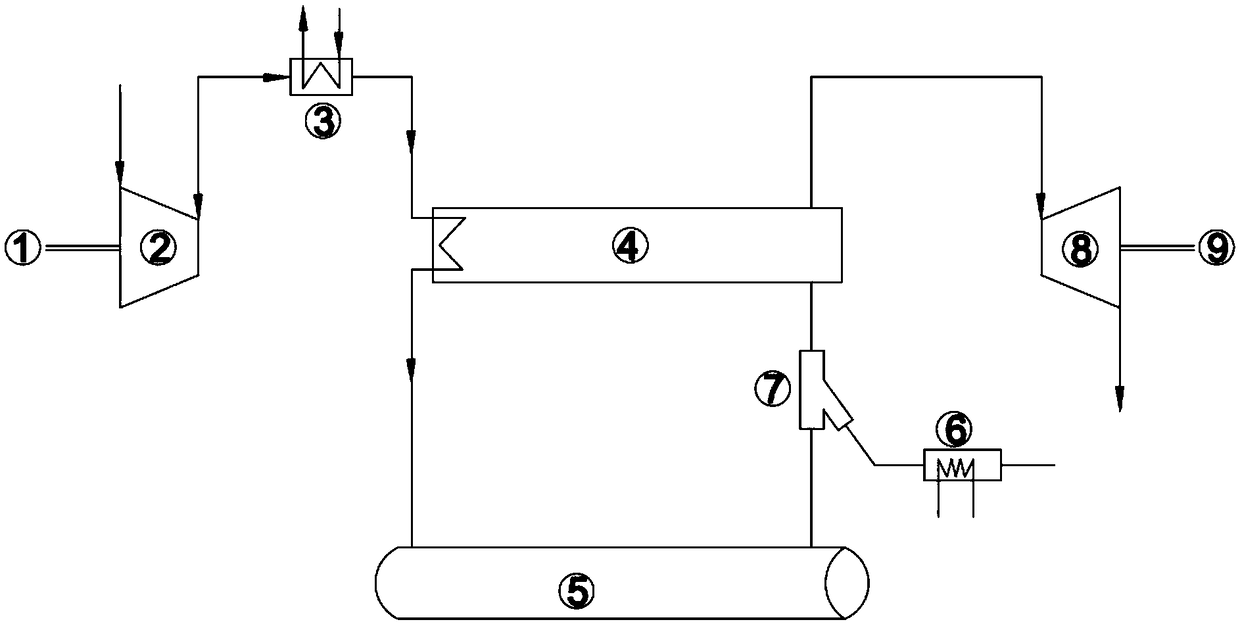

[0030] Such as Figure 1-2 As shown, this embodiment takes a compressed air energy storage power station as an example, and makes a detailed description of the specific structure and working principle of the non-throttling humidification and enthalpy-increasing adiabatic compressed air energy storage system of the present invention.

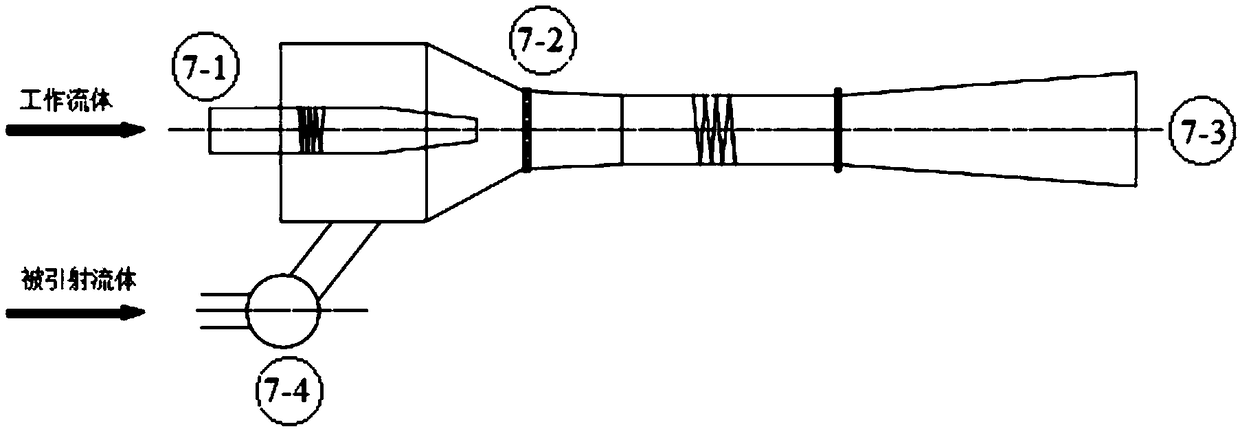

[0031] Such as figure 1 As shown, this embodiment provides an adiabatic compressed air energy storage system with non-throttling humidification and enthalpy increase, including a motor 1, a compressor 2, an air heat exchanger 3, a heat storage device 4, an air storage chamber 5, and water supply Heater 6, ejector flash evaporator 7, turbine 8, generator 9; the outlet of the compressor 2 is connected to the inlet of the air heat exchanger 3 through pipelines, and the outlet of the air heat exchanger 3 is connected to the heat storage device 4. The inlet on the gas side is connected through a pipeline, the outlet on the gas side of the heat storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com