Fuel tank cap with carbon tank function

A fuel tank cap and function technology, which is applied to the charging system, adding non-fuel substances to fuel, machinery/engine, etc. effect of path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

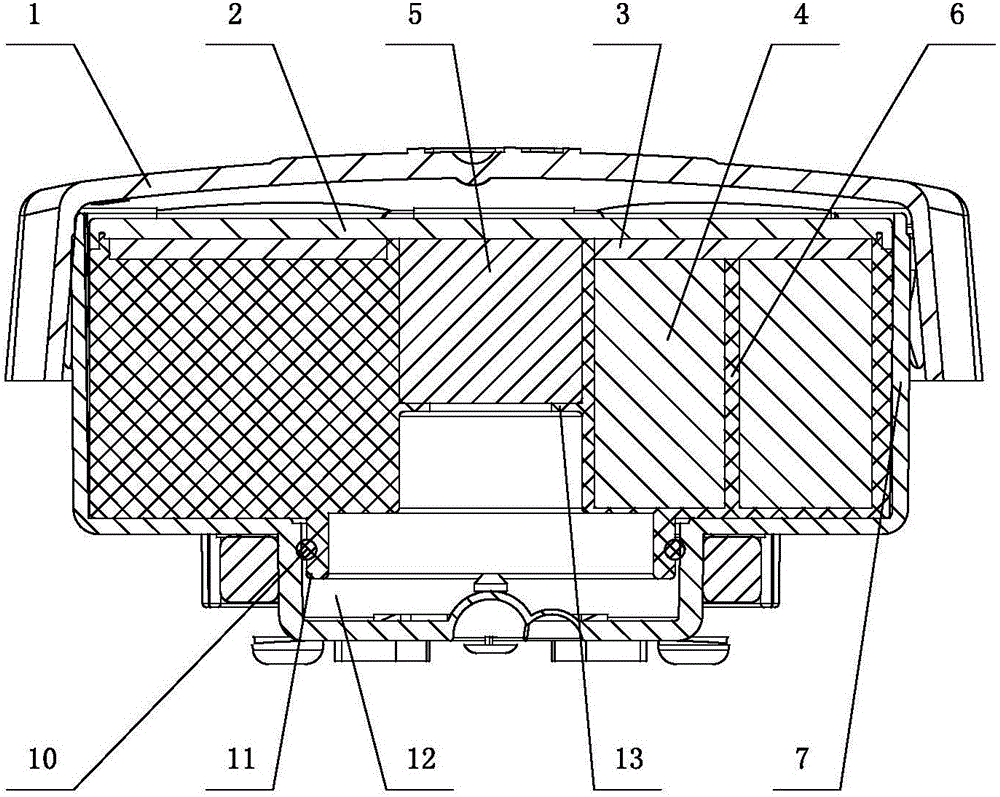

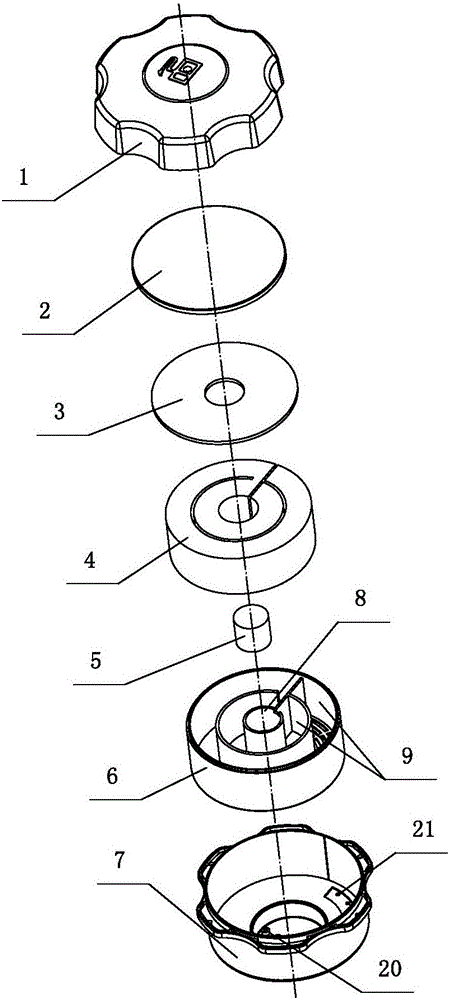

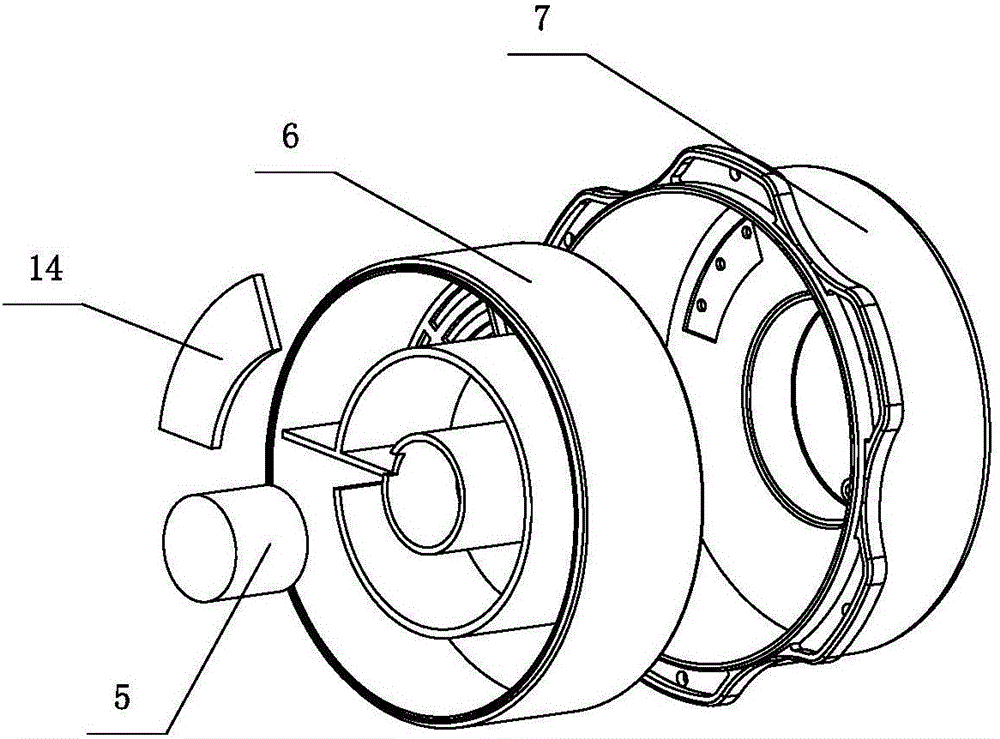

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Depend on Figure 1 to Figure 5 As can be seen from the structural schematic diagram of the fuel tank cap with carbon canister function shown in the present invention, it includes an upper cover 1, a tank body 7 and carbon powder 4, and the carbon powder 4 is filled in the tank body 7, and the tank body 7 is connected with the upper cover 1 . It also includes a support frame 6 for accommodating the toner 4 , the support frame 6 is sleeved in the tank body 7 , and the lower end of the support frame 6 is sealed with the tank body 7 . The support frame 6 has a central pipe column 8 and a continuous channel 9 for extending the oil vapor flow path. The starting end of the continuous channel 9 communicates with the central pipe column 8, and the terminal communicates with the outside of the fuel tank. The bottom of the tank body 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com