Main clutch electrically controlled hydraulic operation mechanism for harvester

A main clutch and electronically controlled hydraulic technology, which is applied to clutches, harvesters, agricultural machinery and implements, etc., can solve problems such as laborious operation and complicated transmission, and achieve the effects of avoiding potential safety hazards, simplifying connection parts, and simplifying the operation of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the accompanying drawings, the technical solution of the present invention will be further described through specific implementation methods, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention .

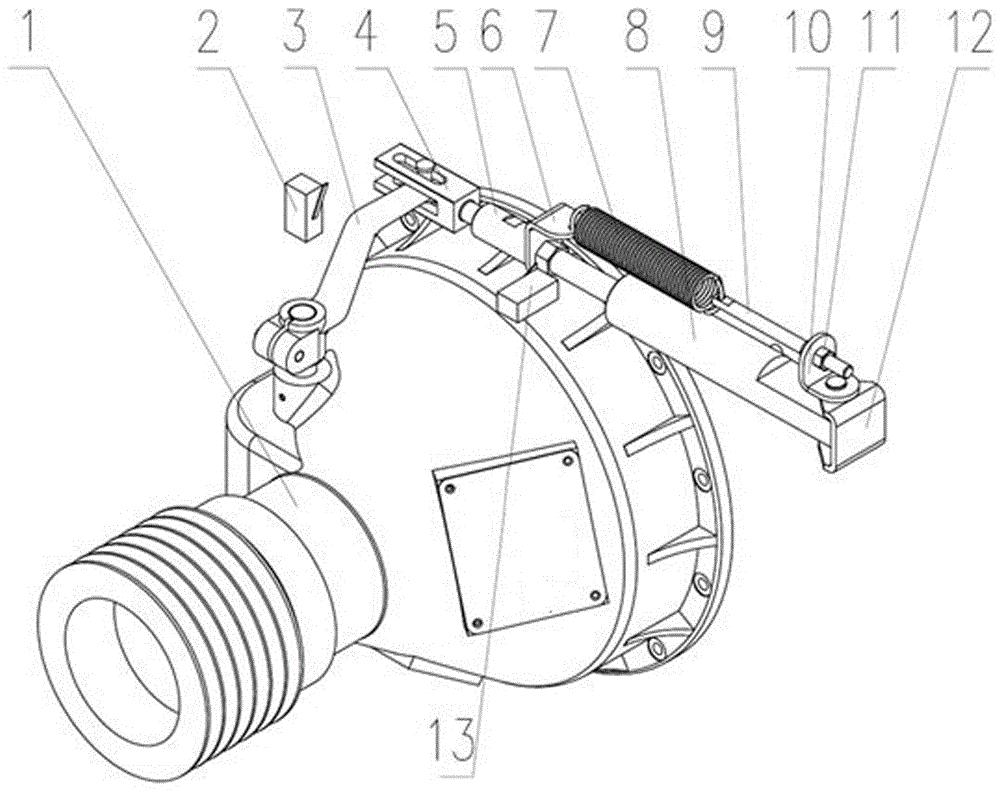

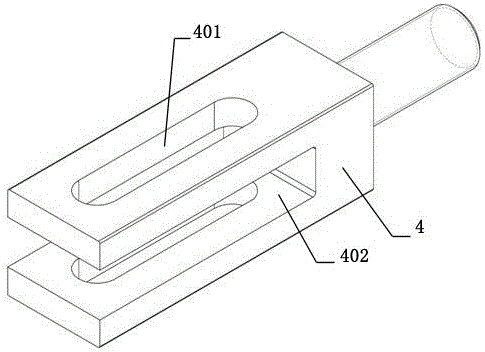

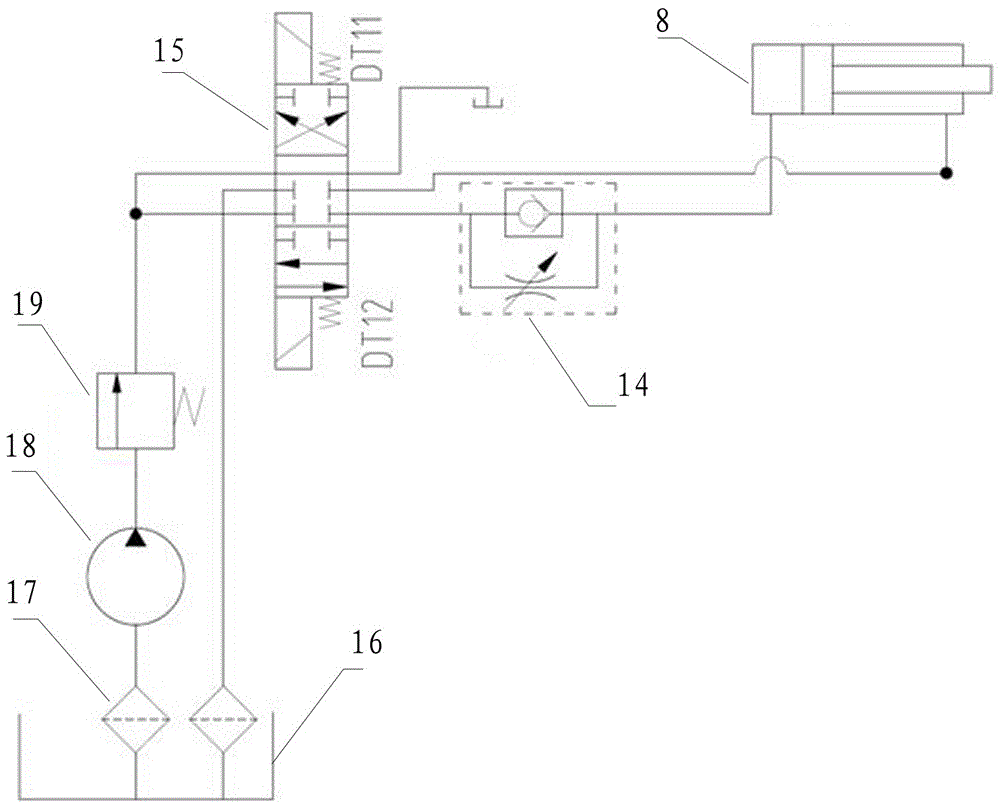

[0018] As shown in the figure, a main clutch electro-hydraulic control mechanism for a harvester includes a main clutch 1, which is connected to the power output end of the engine and controls the combination and separation of the main clutch 1 through a rotating arm 3; it also includes a control main clutch 1. The mechanical part, the electric control part and the hydraulic part of the coupling and separation of the clutch 1; the mechanical part includes the arm connecting fork 4, the connecting sleeve 5, the extension spring 7, the extension spring seat, the adjusting screw 9 and the cylinder seat 12; the electric control part includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com