Front damping spring for automobile and production technology of front damping spring

A production process and front shock absorption technology, applied in the direction of springs, springs/shock absorbers, coil springs, etc., can solve the problems of wear at both ends of the spring, and achieve the effects of reducing pressure, not easy to wear, and good peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

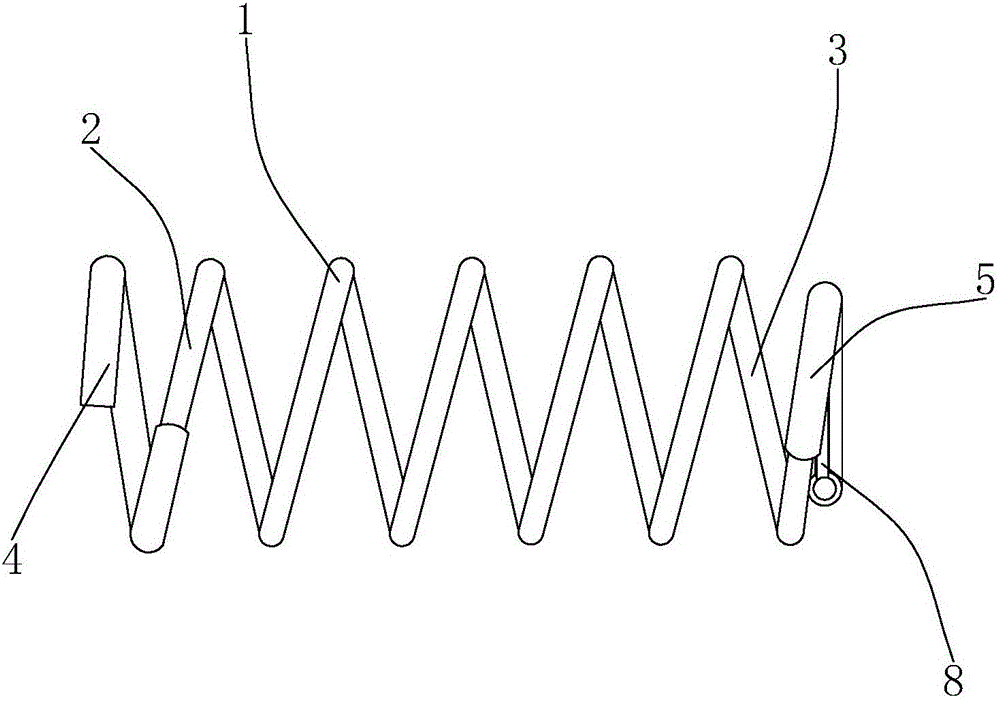

[0033] Embodiment 1: a kind of front damping spring of automobile, as figure 1 As shown, it includes a spring body 1 rolled by spring steel wire. The left side of the spring body 1 is a large end portion 2 , and the right side is a small end portion 3 . The material of the spring steel wire is 55CrSiA, the diameter is 12-13mm, and the hardness is 50-51.5HRC; the inner diameter of the small end 3 is Φ79.5±0.5, the outer diameter of the big end 2 is Φ139.5±0.5, and the number of turns is 7.65 , Free length 456±3mm, rotation to the right.

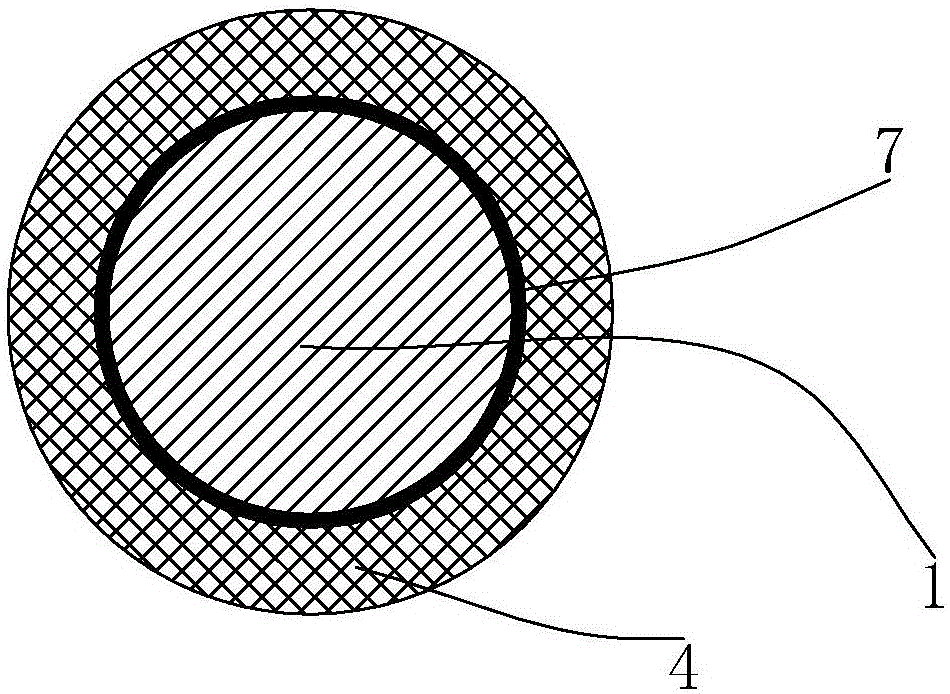

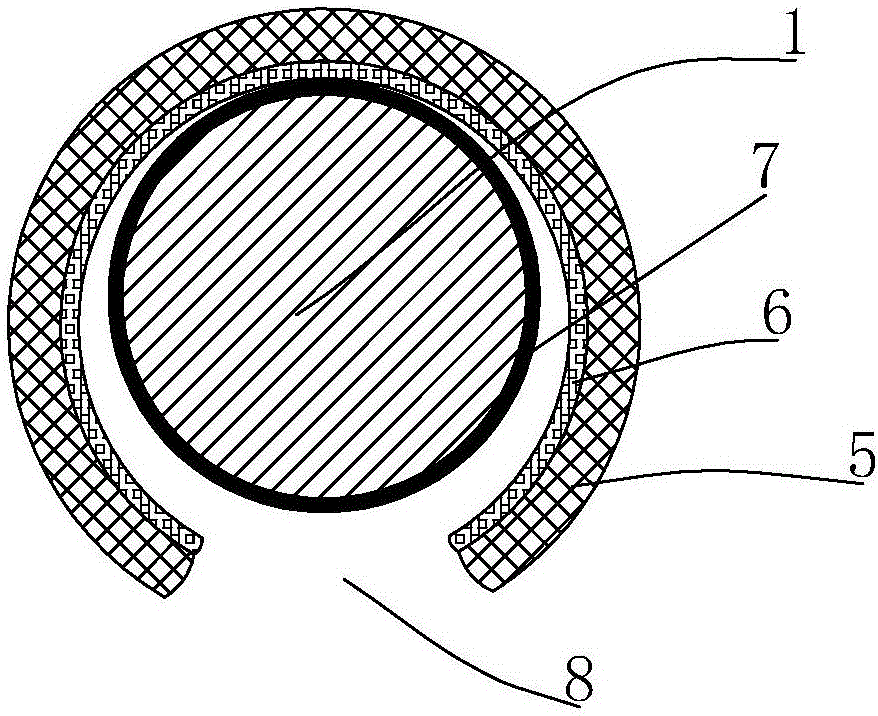

[0034] Such as figure 2 and image 3 As shown, the antistatic paint is sprayed onto the surface of the spring body 1 through a spray gun to form an anti-corrosion layer 7, which can increase the anti-corrosion performance and antistatic performance of the spring body 1.

[0035]At the same time, the first rubber sleeve 4 is set on the large end portion 2 of the spring body 1, and the second rubber sleeve 5 is set on the small end portion 3...

Embodiment 2

[0036] Embodiment 2: a kind of production technology of the front damping spring of automobile, as Figure 1 to Figure 3 As shown, it includes the following steps in turn: preparation process, coil spring process, tempering process, shot peening process, standing process, cleaning process, phosphating operation process, first inspection process, surface spray treatment process, load grouping process, set Rubber cover process, second testing process, packaging process.

[0037] In the preparation process, select spring steel wire made of 55CrSiA, with a diameter of 12-13mm and a hardness of 50-51.5HRC.

[0038] In the spring coiling process, the spring coiling machine is used to operate, and the rotation of the front damping spring is set to the right, and the large end 2 is rolled out first, and then the small end 3 is rolled out; at the same time, the inner diameter of the small end 3 is set Φ79.5±0.5, the outer diameter of the big end 2 is Φ139.5±0.5, the number of turns is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com