A variable temperature dielectric constant measuring cell for liquid and solid-liquid phase transition

A technology of solid-liquid phase change and dielectric constant, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problem of not being able to ensure good contact between the sample and the electrode sheet, limiting the popularity of variable temperature measurement of samples, and improving Problems such as measurement threshold and maintenance difficulty can achieve the effect of improving data repeatability and reliability, ensuring good contact, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

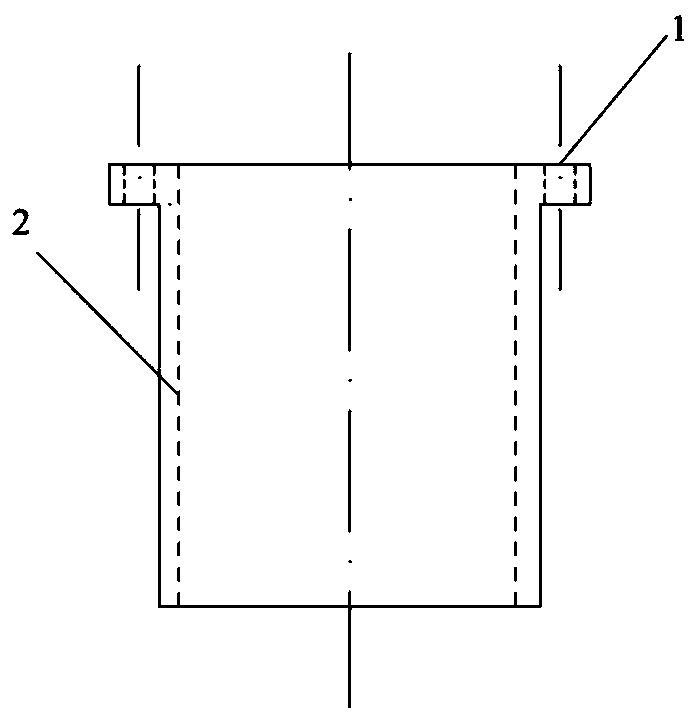

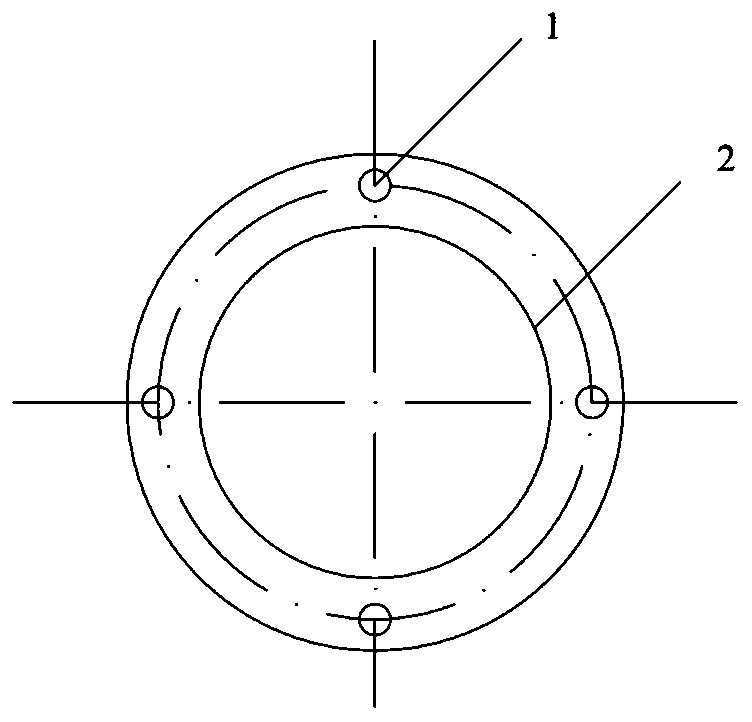

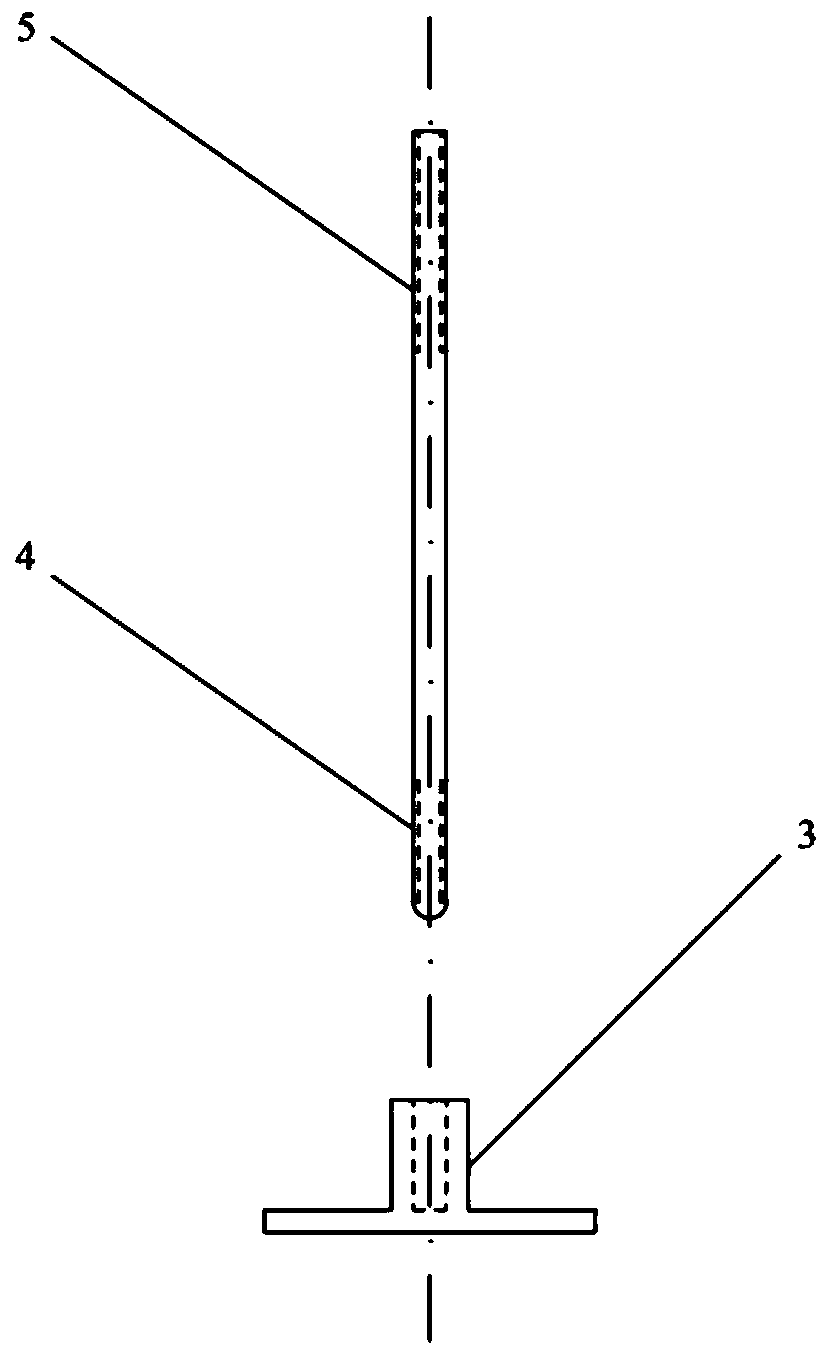

[0037] 1. If Figure 4 , Figure 5 As shown, add O-shaped sealing rings in the sealing groove 8 and sealing groove 11 of the liner, and press them into the Figure 8 In the shell shown in the figure, the inner tank and the shell are fixed through the through hole 6 and the threaded hole 21 by countersunk screws, so that the enclosed internal space forms a shaft seal; at the water inlet 22 and the water outlet 23 on both sides of the shell, Use raw tape to screw in the metal connector to make it sealed; use rubber tubes to connect the metal connector to the constant temperature circulating water bath; start the constant temperature circulating water bath and open the outer circulation to form a closed cycle between the constant temperature circulating water bath and the measuring pool system; adjust the external circulation flux of the circulating water bath machine, and observe whether there is water (or other temperature-changing medium) flowing out from the joint between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com