Cooking fume online monitor for catering industry

A technology of monitoring instrument and catering industry, applied in the direction of instrument, program control, comprehensive factory control, etc., can solve the problems of acquiring wireless communication network signal strength, base station level, time-consuming and laborious, and the power supply voltage cannot be reached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

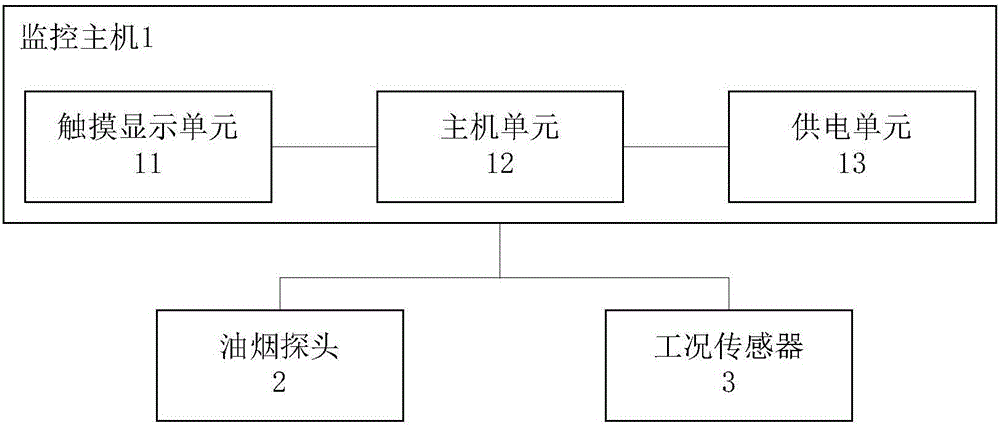

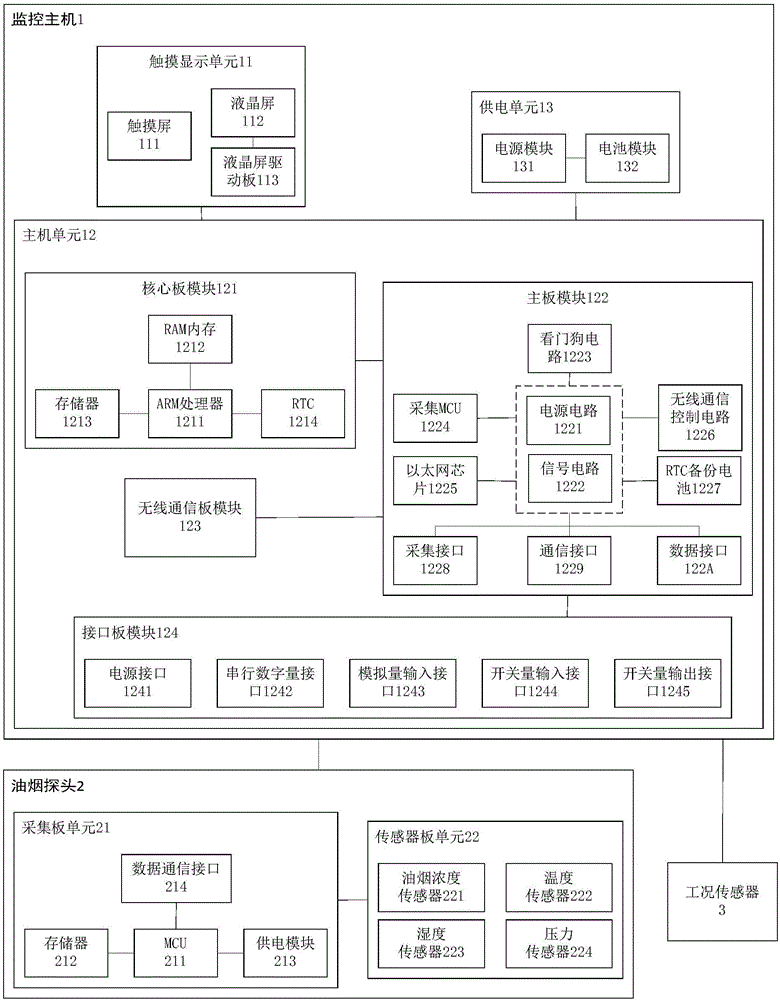

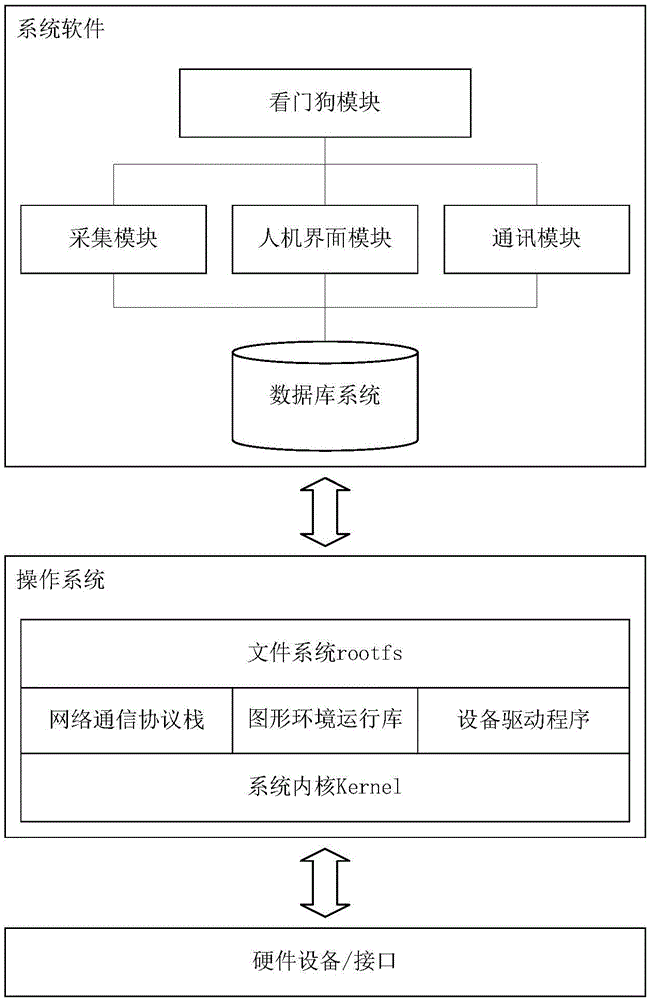

[0036] Embodiment 1: see Figure 1-Figure 3 , an online oil fume monitor in the catering industry, the monitor includes a monitoring host 1, an oil fume probe 2, and a working condition sensor 3, and the monitoring host 1 and the oil fume probe 2 use serial ports, namely RS-232, RS-485 or analog A monitoring host 1 can be connected to multiple oil fume probes 2; the working condition sensor 3 is used to detect the operating status of fans, purifiers and other equipment, which generally uses an AC power sensor, and its working principle is to The AC current of the main loop is converted into a DC4-20mA constant current loop standard signal output in linear proportion. The monitoring host collects the signal through the digital input interface to detect the operating status of fans, purifiers and other equipment. The working condition sensor 4 selects specific specifications according to the power and operating current of the installation site fans, purifiers and other equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com