Device and method for identifying stator resistance of motor

A technology of induction motor and stator resistance, which is used in the control of electromechanical transmission, generator control, motor generator control, etc. It can solve the problems of induction motor model error, reduce vector control performance, etc., and achieve the effect of satisfying high-precision control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the drawings and embodiments.

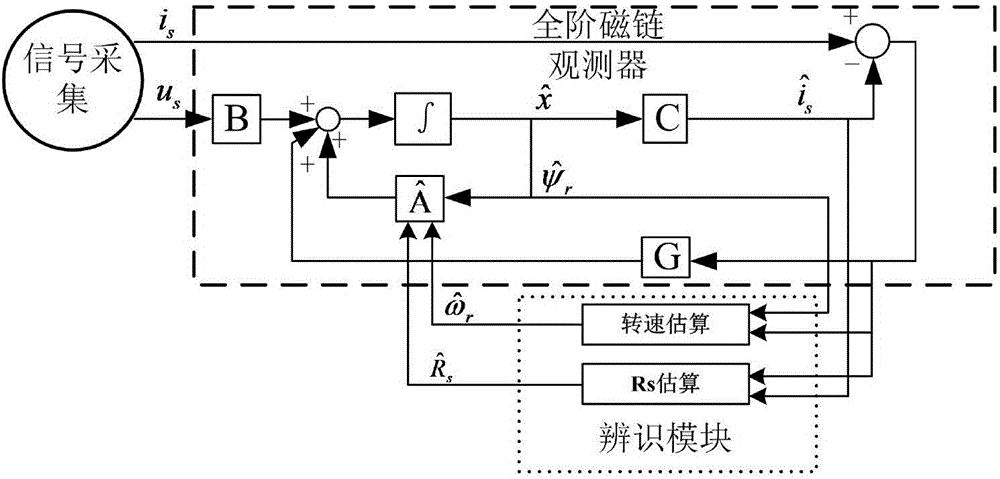

[0030] figure 1 A schematic diagram of a device for identifying the stator resistance of an induction motor. The circular structure is the signal acquisition module, which collects and saves the real-time voltage signal and current signal on the induction motor stator; the virtual short line is divided into a full-order flux observer, and the voltage signal on the induction motor stator is collected by the signal acquisition module And the actual value of the current signal to obtain the estimated value of the stator current of the induction motor and the estimated value of the rotor flux; the dotted line structure is the identification module, according to the estimated value of the induction motor stator current output by the full-order flux observer, the rotor flux The estimated value of the flux linkage and the actual value of the stator current of the induction moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com