A device for connecting a puncturable vial to a container or to a fluid line and transfer of the contents of a puncturable vial into a container or into a fluid line, and method therefor and use of such device

A fluid line, fluid tube technology, applied to a device for coupling a puncture bottle to a container or to a fluid line and transferring the contents of the puncture bottle to the container or to the fluid line, capable of Solve problems such as inapplicable puncture bottles, and achieve the effect of eliminating the risk of injury, eliminating the need for cleaning, and being suitable for manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

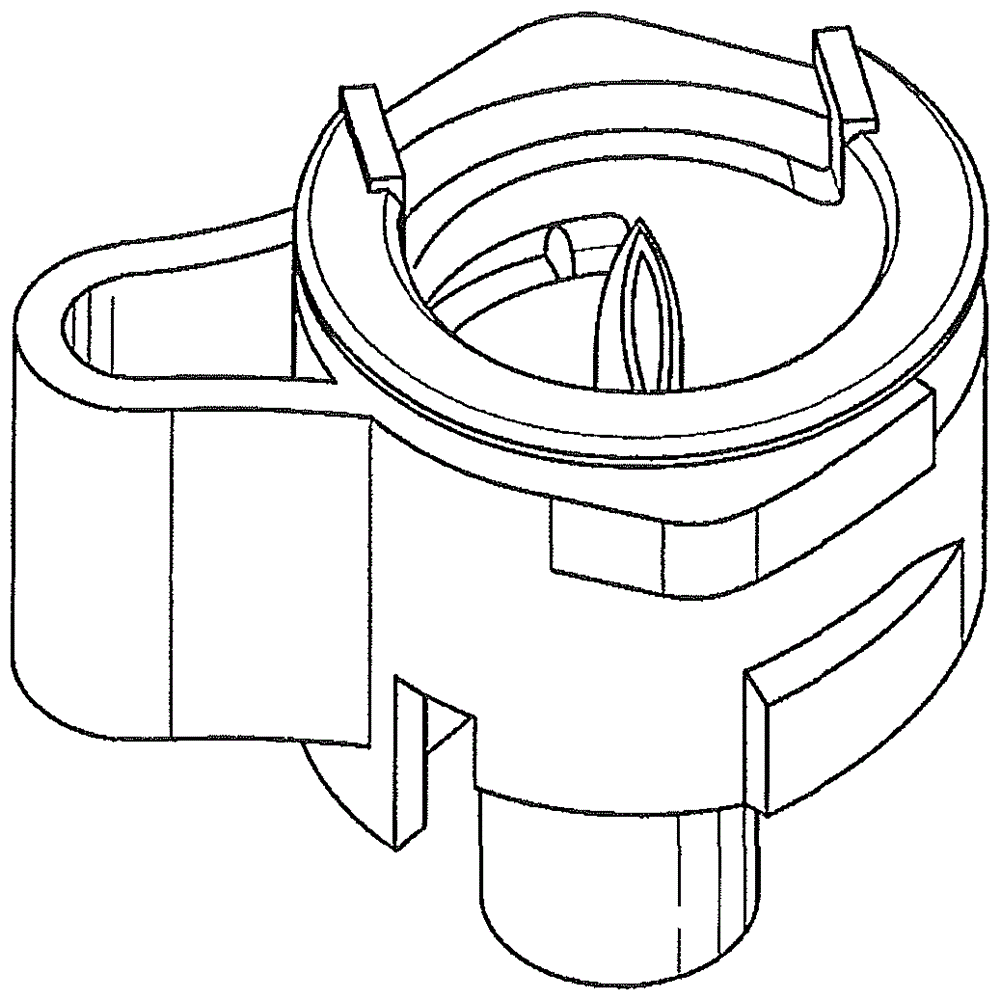

[0070] figure 1 A simplified schematic illustration showing the construction of an infusion device into which the device according to the invention can be integrated.

[0071] For the infusion of medical solutions, a hose set (23) is used, which is connected to the patient through the vascular access of the vein. The contents of the infusion container (25) flow by means of gravity into the patient via the droplet chamber (24) or are introduced to the patient via the pump (26). The injection site (28) for the medicine can be integrated into the hose set. Said injection site (28) is suitable for coupling the device (2) according to the invention. It is also possible to couple the device according to the invention at the droplet chamber (24). The device according to the invention can furthermore be designed as an integral part of the infusion tube set.

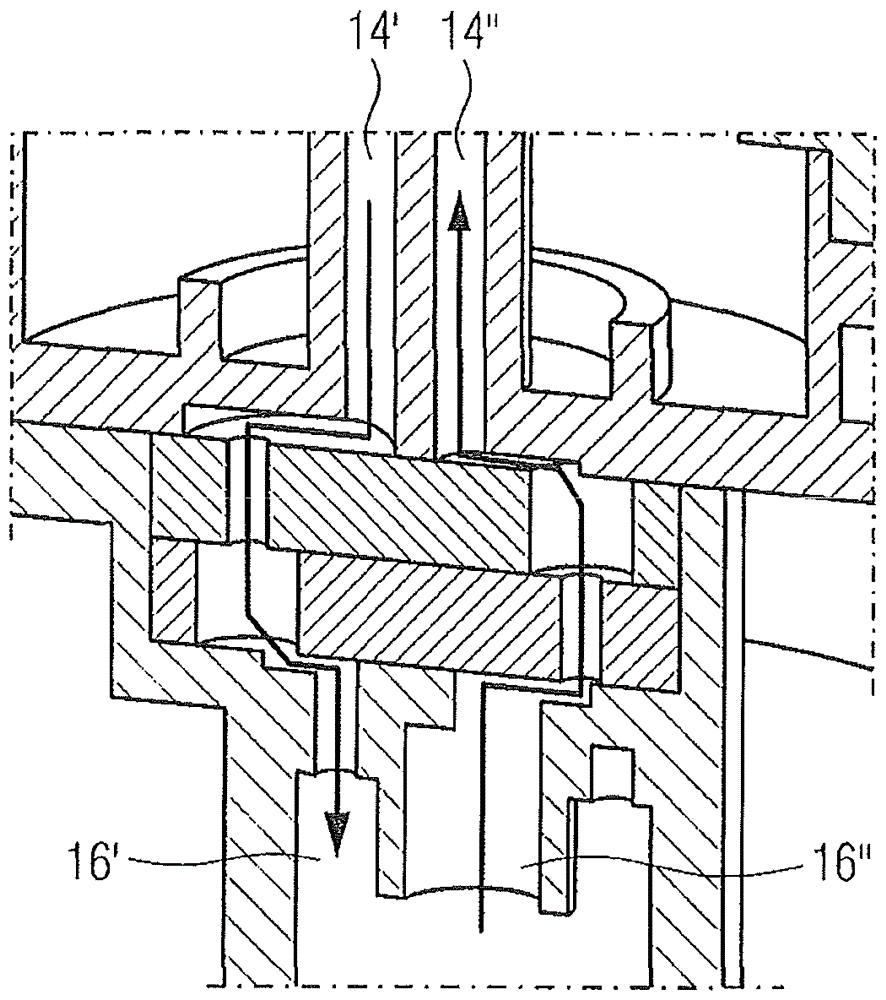

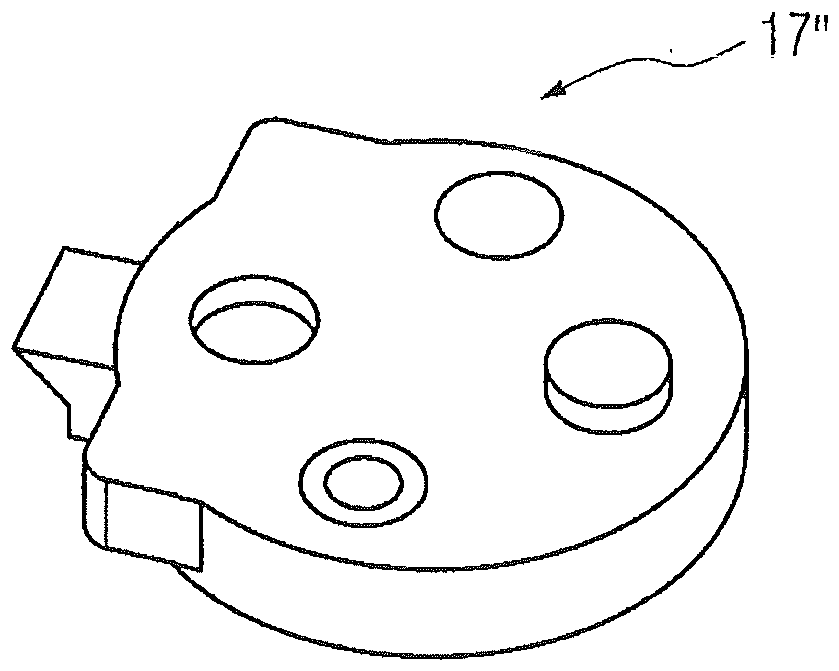

[0072] figure 2 A simplified schematic illustration showing the construction of an extracorporeal therapy device as an ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap