Preparation method of a novel pesticide bovine serum albumin-thiacloprid nanoparticle

A bovine serum albumin and nanoparticle technology, which is applied in the field of preparation of new pesticide bovine serum albumin-thiacloprid nanoparticles, can solve the problems of difficult long-term storage, difficult transportation, obvious burst release phenomenon, etc., and achieves low equipment requirements. , the process is simple, the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

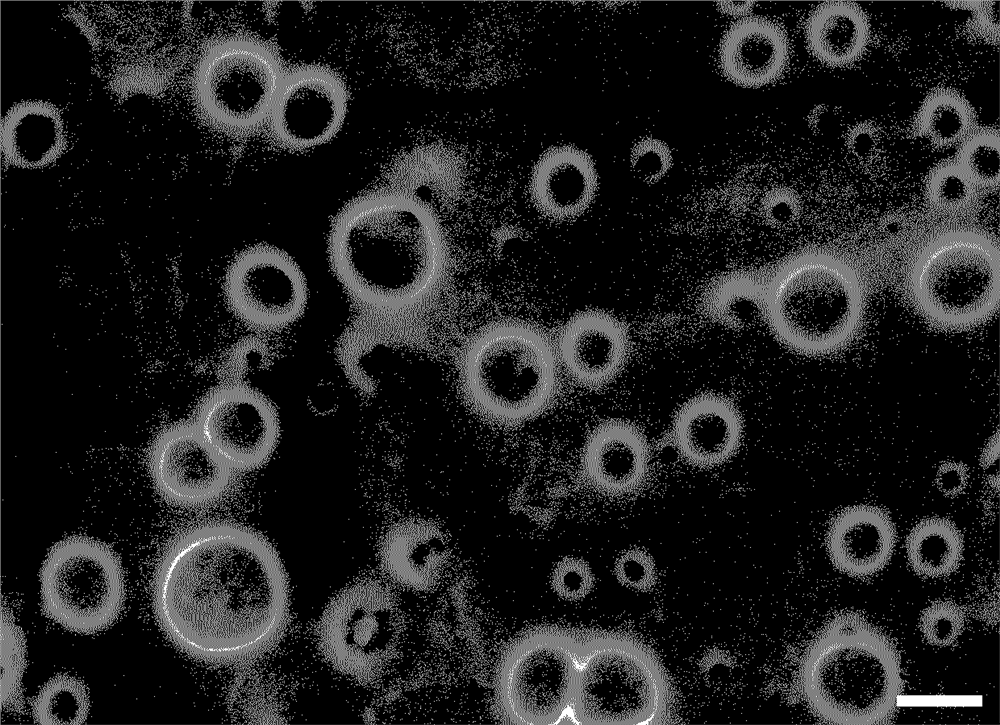

Image

Examples

Embodiment 1

[0025] (1) Take 0.08g of bovine serum albumin in 4ml of double-distilled water to prepare an aqueous phase, 50 o C water bath for 30min to obtain clear and transparent bovine serum albumin aqueous solution;

[0026] (2) Take another 1 mg of thiacloprid, add 0.167 ml of acetonitrile to dissolve by ultrasonic for 5 minutes, and prepare 6 mg / mL of thiacloprid-acetonitrile oil phase;

[0027] (3) Adjust the rotational speed of the water phase to 1000rpm, add the thiacloprid-acetonitrile oil phase dropwise under high-speed stirring, emulsify for 30min, and take out the emulsion quickly at 0-4. o Cool down for 10min at C, then take out the ultrasound for 10min to obtain bovine serum albumin-thiacloprid ultramicroemulsion;

[0028] (4) Dialyze the ultra-microemulsion dialysis membrane (MWCO=5000) overnight, take out the dialysate, freeze, and freeze-dry to obtain white powder, namely thiacloprid albumin nanoparticles.

Embodiment 2

[0030] (1) Take 0.08g of bovine serum albumin in 4ml of double-distilled water to prepare an aqueous phase, 50 o C water bath for 30min to obtain clear and transparent bovine serum albumin aqueous solution;

[0031] (2) Take another 2 mg of thiacloprid, add 0.334 ml of acetonitrile to dissolve it by ultrasonic for 5 minutes, and prepare 6 mg / mL of thiacloprid-acetonitrile oil phase;

[0032] (3) Adjust the rotation speed of the water phase to 1000rpm, add the thiacloprid-acetonitrile oil phase dropwise under high-speed stirring, emulsify for 40min, and take out the emulsion quickly at 0-4. o Cool down for 10min at C, then take out the ultrasound for 10min to obtain bovine serum albumin-thiacloprid ultramicroemulsion;

[0033] (4) Dialyze the ultra-microemulsion dialysis membrane (MWCO=5000) overnight, take out the dialysate, freeze, and freeze-dry to obtain white powder, namely thiacloprid albumin nanoparticles.

Embodiment 3

[0035] (1) Take 0.08g of bovine serum albumin in 4ml of double-distilled water to prepare an aqueous phase, 50 o C water bath for 30min to obtain clear and transparent bovine serum albumin aqueous solution;

[0036] (2) Take another 3 mg of thiacloprid, add 0.501 ml of acetonitrile to dissolve it by ultrasonic for 10 minutes, and prepare 6 mg / mL of thiacloprid-acetonitrile oil phase;

[0037] (3) Adjust the rotational speed of the water phase to 1200rpm, add the thiacloprid-acetonitrile oil phase dropwise under high-speed stirring, emulsify for 40min, and take out the emulsion quickly at 0-4. o Cool down for 5min at C, then take out ultrasonic wave for 10min to obtain bovine serum albumin-thiacloprid ultramicroemulsion;

[0038] (4) Dialyze the ultra-microemulsion dialysis membrane (MWCO=5000) overnight, take out the dialysate, freeze, and freeze-dry to obtain white powder, namely thiacloprid albumin nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com