Paper additive and preparation method thereof

An additive and paper technology, applied in the field of fine chemicals, can solve the problems of single function of paper additives, toxic and side effects of human body, etc., and achieve the effect of mature reaction method, low toxic and side effects, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

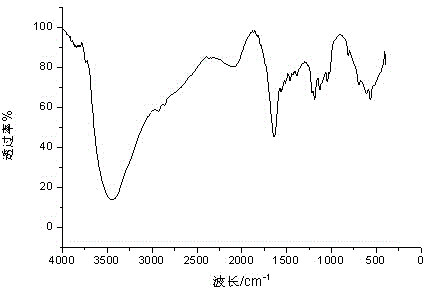

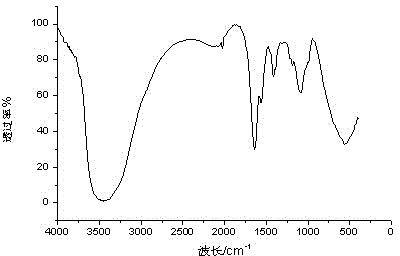

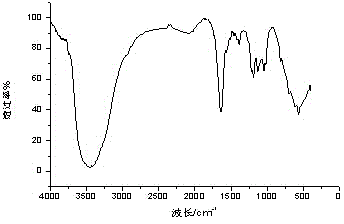

Image

Examples

Embodiment 1

[0027] A paper additive, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0028] Antibacterial agent polyhexamethylene guanidine hydrochloride 0.6 parts

[0029] Carboxymethyl chitosan 1 part

[0030] Condensing agent 0.4 part

[0031] Activator 0.1 parts

[0032] 0.05 parts of crosslinking agent;

[0033] The condensing agent is 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide;

[0034] The activator is N-hydroxysuccinimide;

[0035] The crosslinking agent is N,N dimethylbisacrylamide.

[0036] 1 part of carboxymethyl chitosan is dissolved in deionized water to obtain a carboxymethyl chitosan aqueous solution with a mass percentage concentration of 2%, and then use a mass percentage concentration of 36.5% hydrochloric acid to adjust the pH to 5-5.5, and then Add 0.1 parts of activator N-hydroxysuccinimide and 0.4 parts of condensing agent 1-(3-dimethylaminopropyl)-3-e...

Embodiment 2

[0061] A paper additive, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0062] Antibacterial agent polyhexamethylene guanidine hydrochloride 2 parts

[0063] Carboxymethyl chitosan 2 parts

[0064] Condensing agent 1.2 parts

[0065] Activator 0.3 parts

[0066] 0.1 part of crosslinking agent;

[0067] The condensing agent is 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDCI);

[0068] The activator is N-hydroxysuccinimide (NHS);

[0069] The crosslinking agent is N,N dimethylbisacrylamide.

[0070] The preparation method of above-mentioned a kind of paper additive specifically comprises the following steps:

[0071] 2 parts of carboxymethyl chitosan are dissolved in deionized water to obtain a carboxymethyl chitosan aqueous solution with a mass percentage concentration of 2%, and then the pH is adjusted to 5-5.5 with a 36.5% aqueous hydrochloric acid solution w...

Embodiment 3

[0073] A paper additive, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0074] Antibacterial agent polyhexamethylene guanidine hydrochloride 3 parts

[0075] Carboxymethyl chitosan 2 parts

[0076] condensing agent 1 part

[0077] Activator 0.25 parts

[0078] 0.08 parts of crosslinking agent;

[0079] The condensing agent is 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide;

[0080] The activator is N-hydroxysuccinimide;

[0081] The crosslinking agent is N,N dimethylbisacrylamide.

[0082] The preparation method of above-mentioned a kind of paper additive specifically comprises the following steps:

[0083] 2 parts of carboxymethyl chitosan are dissolved in deionized water to obtain a carboxymethyl chitosan aqueous solution with a mass percentage concentration of 2%, and then the pH is adjusted to 5-5.5 with a 36.5% aqueous hydrochloric acid solution with a mass pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com