Fermented milk with DHA (dehydroascorbic acid) and EPA (eicosapentaenoic acid) and preparation method thereof

A technology of fermented milk and milk, which is applied in the preparation of fermented milk and the field of fermented milk, can solve problems such as bad flavor, and achieve the effect of satisfying taste enjoyment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

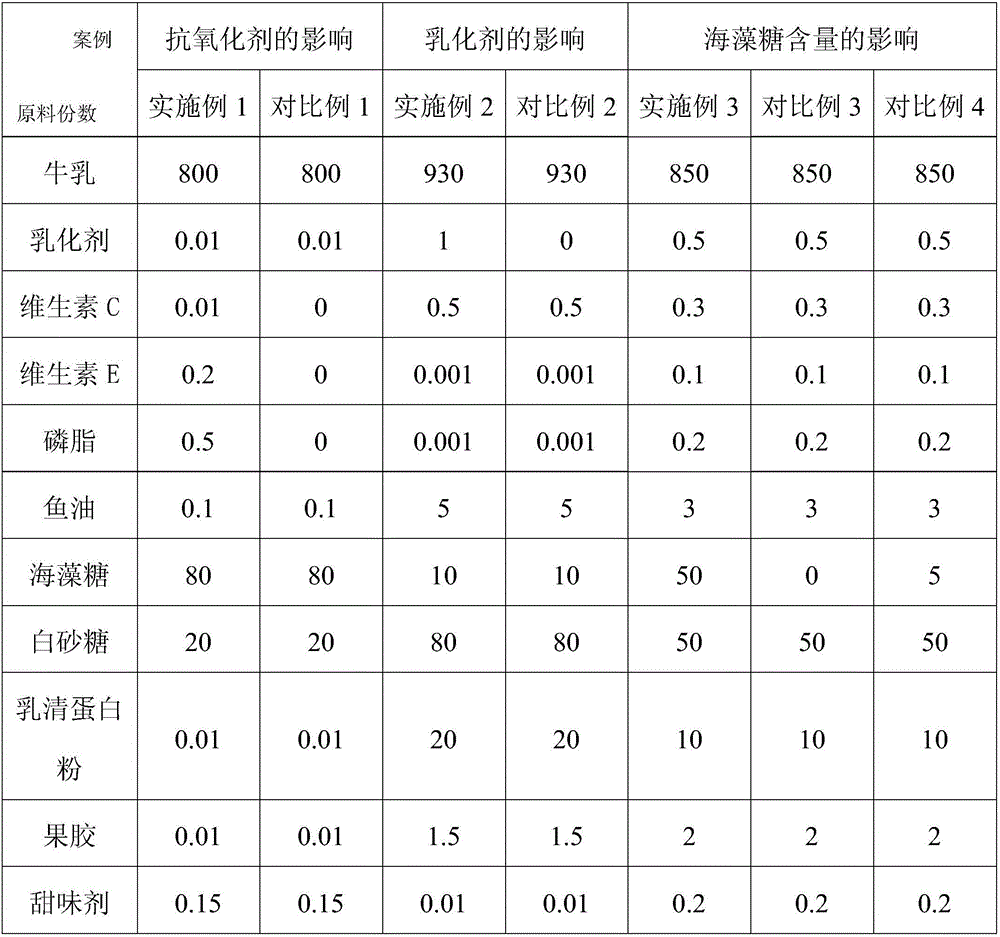

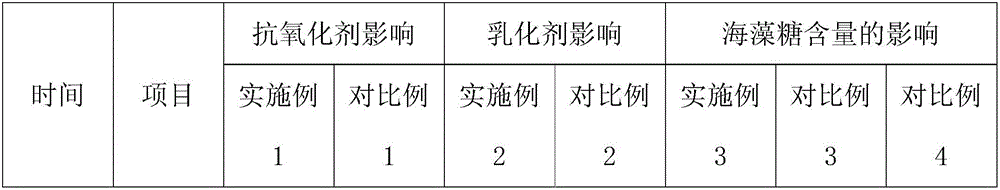

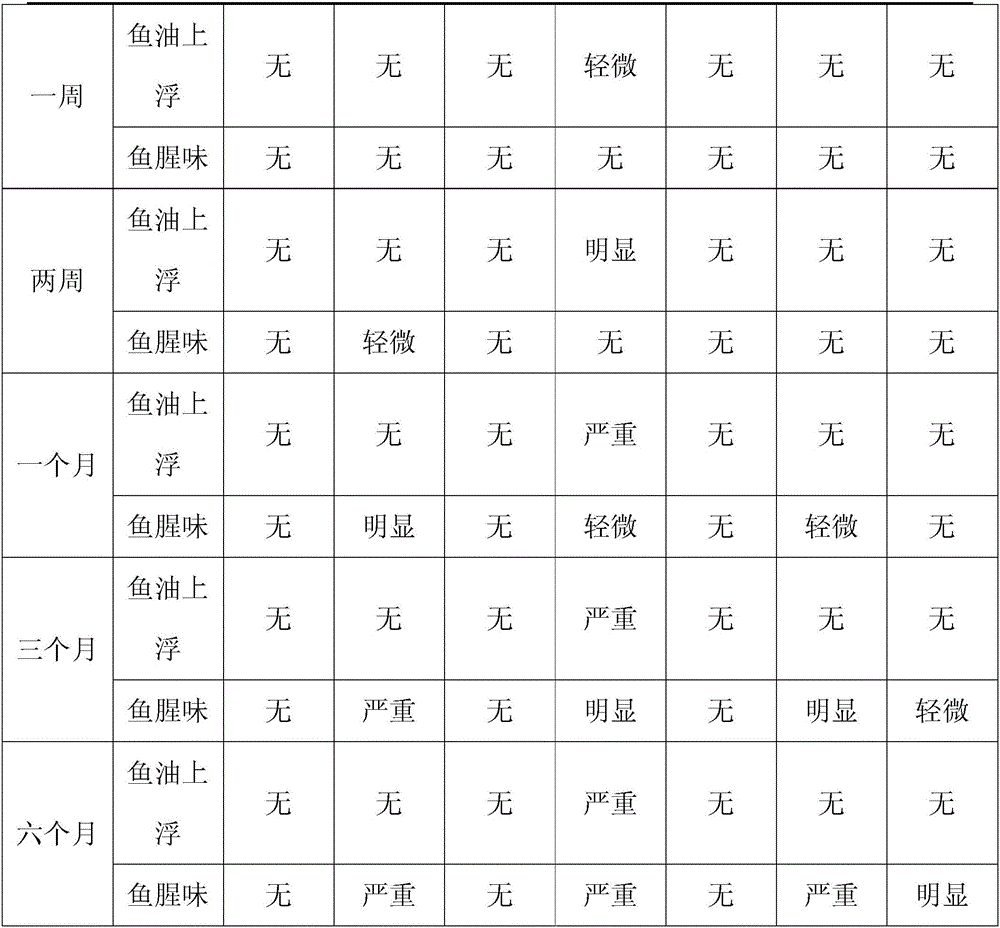

[0047] The content information of raw materials in each case is shown in the table below:

[0048] Each embodiment of table 1 and comparative example raw material content table

[0049]

[0050] The preparation method of the fermented milk containing DHA and EPA in embodiment 1-3, comparative example 1-4 comprises the following steps:

[0051] a. Fish oil pre-emulsification treatment: add emulsifier, antioxidant, and fish oil in sequence to 10% milk at 40-70°C, use shearing and stirring for 1-5 minutes to make it evenly dispersed, and then perform homogenization treatment. The homogenization temperature is 58-70°C, and the homogenization pressure is 10-20MPa to obtain a pre-emulsified base material;

[0052] b. Heat up 10% milk to 50-70°C, add whey protein powder and stabilizer, disperse evenly and mix with the remaining milk, then add trehalose, white sugar and sweetener in a loop, mix well, then cool down to below 35°C to obtain ingredient milk;

[0053] c. Mixing the ...

Embodiment 4

[0065] Embodiment 4, comparative example 5-7 The preparation method of the fermented milk that contains DHA and EPA comprises the following steps:

[0066] a. Fish oil pre-emulsification treatment: add 0.4 part of emulsifier, 0.3 part of vitamin C, 0.1 part of vitamin E, 0.2 part of phospholipid, 3 parts of fish oil to 90 parts of milk at temperature t, and use shearing and stirring for 1-5 minutes to make It is uniformly dispersed, and then subjected to homogenization treatment, with a homogenization temperature of 58-70°C and a homogenization pressure of 10-20MPa to obtain a pre-emulsified base material;

[0067] b. Heat up 90 parts of milk to 50-70°C, add 10 parts of whey protein powder and 2 parts of pectin, disperse evenly and mix with 720 parts of milk, then add 70 parts of trehalose, 30 parts of white sugar, 0.1 part sweetener, make it evenly mixed, cool down to below 35°C, and obtain ingredient milk;

[0068] c. Mix the pre-emulsified base material and the ingredient ...

Embodiment 5

[0079] A preparation method of sterilized fermented milk containing DHA and EPA, the preparation method comprises the following steps:

[0080] a. Fish oil powder pretreatment: Add 0.5 parts of emulsifier, 0.3 parts of vitamin C, 0.1 parts of vitamin E, 0.2 parts of phospholipids, and 5 parts of fish oil powder to 90 parts of milk at 65±5°C in order, and maintain 65±5°C Shear and stir for 1 minute to make it evenly dispersed to obtain the pretreated base material;

[0081] b. Warm up the remaining 90 parts of milk to 65±5°C, add 10 parts of whey protein powder and 2 parts of pectin, disperse evenly, add 60 parts of trehalose, 40 parts of white sugar, and sweetener to the cold milk cycle 0.1 part, make it mix evenly, cool down to below 35°C, and get the ingredient milk;

[0082] c. Mix the pretreated base material and the ingredient milk evenly, and prepare fermented milk containing DHA and EPA after homogenization, sterilization, fermentation, cooling and sterilization.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com