Anti-slippery shoe and preparation method thereof

A technology of anti-slip and anti-slip teeth, which is applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of inability to guarantee anti-slip, easy to get stuck in the main stone and sediment, and uneven force applied to the anti-slip part, and achieve good grip and anti-slip effect. Lightweight and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

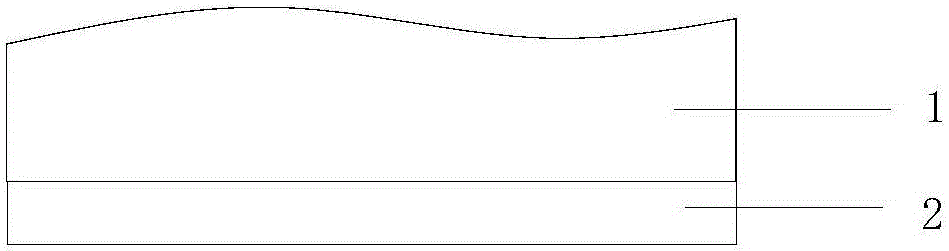

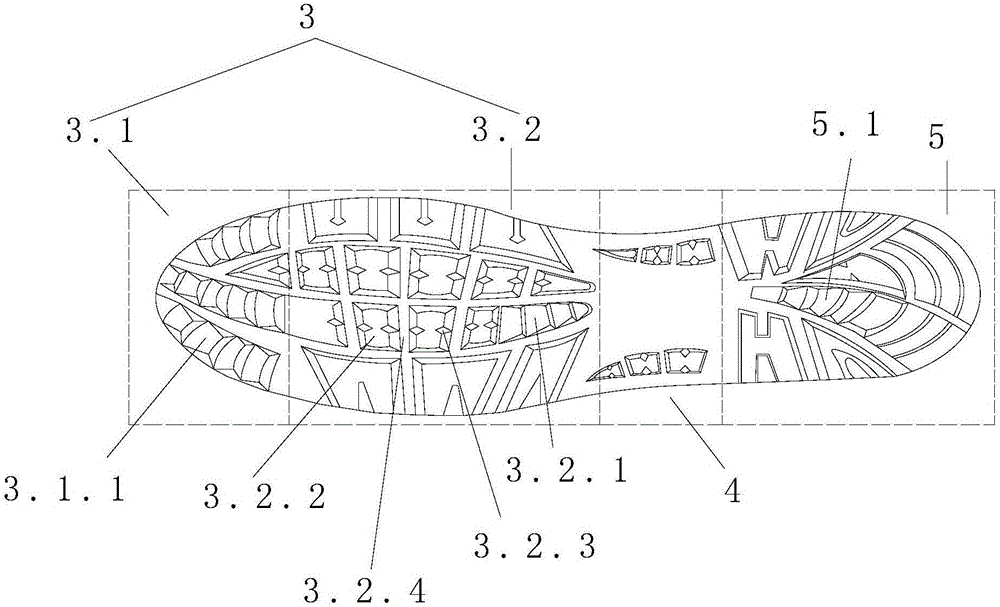

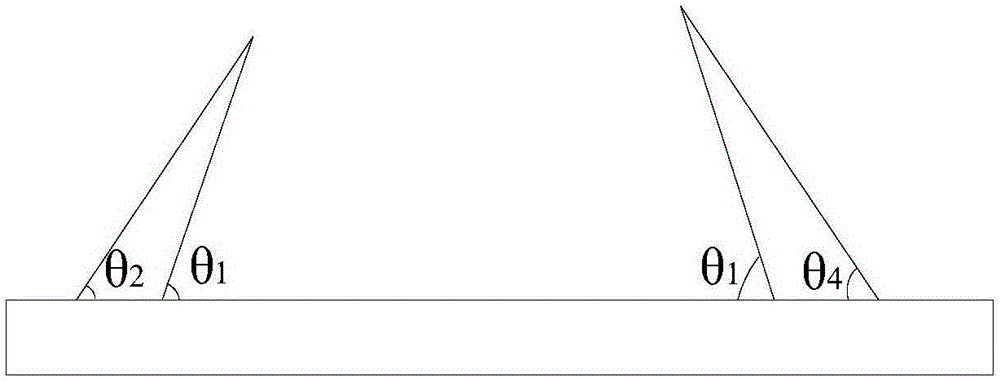

[0029] A kind of non-slip shoes, comprising a shoe body 1 and a sole 2, the sole 2 is sequentially provided with a forefoot part 3, an arch part 4 and a heel part 5 along the shoe length direction, and the forefoot part 3 includes a toe part 3.1 and a sole 3.2, the toe part 3.1 is provided with the first anti-slip teeth 3.1.1 inclined towards the arch of the foot 4, the heel 5 is provided with the second anti-slip teeth 5.1 inclined towards the arch of the foot 4, the sole of the foot 3.2 The side near the arch of the foot is provided with the third anti-slip teeth 3.2.1 inclined towards the arch of the foot 4 .

[0030] The sole portion 3.2 is provided with an anti-slip platform 3.2.2, and the end face of the anti-slip platform 3.2.2 is an arc-shaped concave surface; A drainage groove 3.2.3 is provided at the junction of the two, and a groove 3.2.4 is provided between any two adjacent anti-skid platforms 3.2.2, and the width of the notch of the groove 3.2.4 is greater than th...

Embodiment 2

[0039] The first anti-skid tooth 3.1.1 of the sole and the second anti-skid tooth 5.1 are prepared by the following method: Weigh 60 parts of raw material nitrile rubber, 40 parts of EPDM rubber, 9 parts of zinc oxide, zirconia 12 parts, 10 parts of stearic acid, 4 parts of light calcium, 5 parts of white carbon black, 16 parts of glass fiber, 3 parts of accelerator, 3 parts of tackifier, 4 parts of anti-aging agent, 3 parts of vulcanizing agent, put into kneader, Knead at a temperature of 500°C for 10 minutes to obtain mold materials for the first anti-skid tooth 3.1.1 and the second anti-skid tooth 5.1.

[0040] The anti-slip platform 3.2.2 of the sole is prepared by the following method: Weigh 60 parts of raw material natural rubber, 7 parts of polyolefin elastomer, 3 parts of aluminum oxide, 4 parts of potassium carbonate, 10 parts of stearic acid, white carbon black 5 parts, 3 parts of accelerator, 3 parts of tackifier, 4 parts of anti-aging agent, 3 parts of vulcanizing ...

Embodiment 3

[0047] The first anti-skid tooth 3.1.1 of the sole and the second anti-skid tooth 5.1 are prepared by the following method: Weigh 50 parts of raw material nitrile rubber, 30 parts of EPDM rubber, 6 parts of zinc oxide, zirconium oxide 10 parts, 7 parts of stearic acid, 3 parts of light calcium, 4 parts of white carbon black, 14 parts of glass fiber, 2 parts of accelerator, 2 parts of tackifier, 3 parts of anti-aging agent, 2 parts of vulcanizing agent, put into kneader, Knead at a temperature of 400°C for 15 minutes to obtain mold materials for the first anti-skid tooth 3.1.1 and the second anti-skid tooth 5.1.

[0048] The anti-slip platform 3.2.2 of the sole is prepared by the following method: Weigh 50 parts of raw material natural rubber, 6 parts of polyolefin elastomer, 2 parts of aluminum oxide, 3 parts of potassium carbonate, 7 parts of stearic acid, white carbon black 4 parts, 2 parts of accelerator, 2 parts of tackifier, 3 parts of anti-aging agent, 2 parts of vulcani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com