Paper diaper

A technology of diapers and toilet paper, applied in the field of diapers, can solve the problems of waste materials, user discomfort, poor urine absorption effect, etc., achieve broad market prospects, good ventilation effect, and good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail:

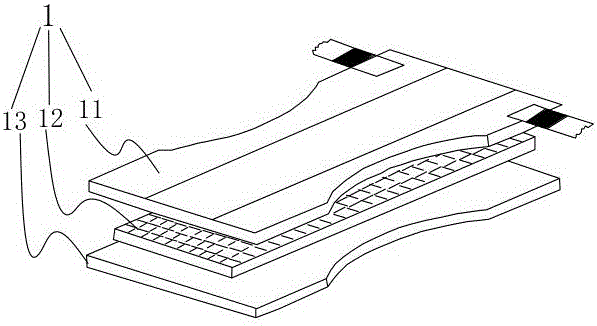

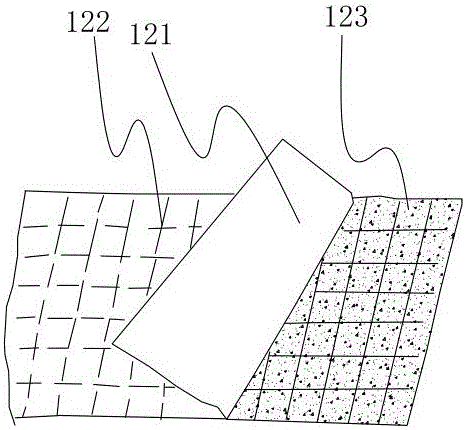

[0017] Such as figure 1 , figure 2 As shown, a diaper includes a diaper body 1, and the diaper body 1 is respectively provided with a non-woven fabric layer 11, an absorbent core 12, and a composite breathable bottom layer 13 from top to bottom, and the absorbent core 12 is made of two layers of toilet paper 121. A layer of reticulated ribs 122, a polymer absorbent material 123 and an adhesive layer. Between the two layers of toilet paper 121, there is a layer of reticulated ribs 122 intersecting in a grid. The polymer The absorbent material 123 is evenly distributed in each grid of the reticulated ribs 122, and each two layers of toilet paper 121 and the reticulated ribs 122 are bonded by an adhesive layer, and the toilet paper 121 in each layer is wood pulp paper The reticulated wire reinforcement 122 of each layer is cotton thread or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com