White tea extract and preparation method and application thereof

A white tea extract and white tea technology are applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations and other directions, and can solve the problems of browning of the color of the extract, long extraction time, and deteriorating flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

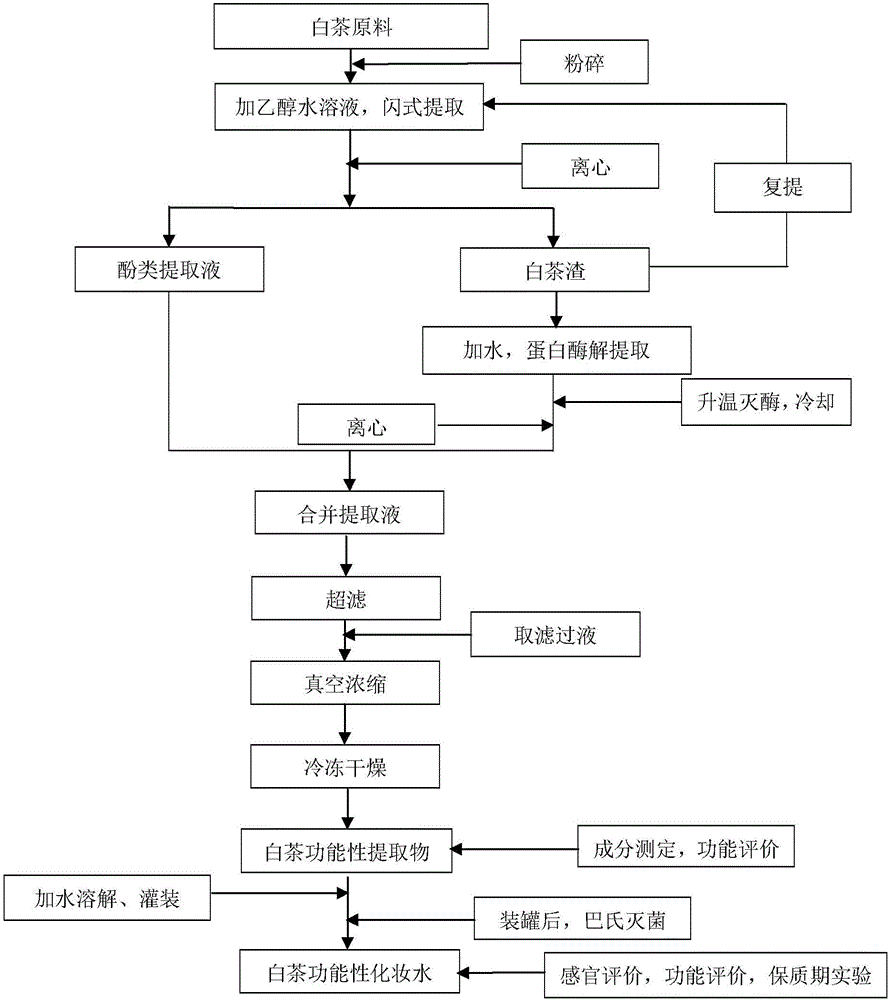

Method used

Image

Examples

Embodiment 1

[0046] (1) Get 1 kg of raw white tea (manufacturer: Fujian Dinghao Tea Co., Ltd.; product name: Shoumei; quality grade: special grade; net content 600g / bag, aluminum foil packaging, carton outer packaging), crush and sieve to 50 mesh, According to the mass ratio of material to liquid 1:20, mix with 20L ethanol water solution with a volume fraction of 60%, and extract at room temperature for 2 minutes with a flash type (pilot-type flash extraction apparatus, JHBE-100A, Henan Jinnai Technology Development Co., Ltd.), with a rotation speed of 5000r / min Centrifuge to remove slag (desktop low-speed centrifuge, TD5A-WS, equipped with 851400 horizontal rotor, Xiangyi Centrifuge Instrument Co., Ltd.), 4000r / min (3040xg), collect the centrifuged supernatant, and collect the residue after flash re-extraction once. , the combined supernatant obtained each time is the flash extract;

[0047] (2) Get the filter residue collected in step (1), add 20L of pure water, mix in a 50L stainless st...

Embodiment 2

[0062] (1) Get 1kg of raw white tea (manufacturer: Fujian Dinghao Tea Co., Ltd.; product name: Shoumei; quality grade: special grade; net content 600g / bag, aluminum foil packaging, carton outer packaging), crush and sieve to 60 mesh, According to the mass ratio of material to liquid 1:30, mix with 30L ethanol water solution with a volume fraction of 70%, and extract at room temperature for 3 minutes with a flash type (pilot-type flash extraction apparatus, JHBE-100A, Henan Jinnai Technology Development Co., Ltd.), with a rotation speed of 5000r / min Centrifuge to remove slag (desktop low-speed centrifuge, TD5A-WS, equipped with 851400 horizontal rotor, Xiangyi Centrifuge Instrument Co., Ltd.), 4000r / min (3040xg), collect the centrifuged supernatant, and collect the residue after flash re-extraction once. , the combined supernatant obtained each time is the flash extract;

[0063] (2) Get the filter residue collected in step (1), add 20L of pure water, mix in a 50L stainless ste...

Embodiment 3

[0077] (1) Get 1kg of raw white tea (manufacturer: Fujian Dinghao Tea Co., Ltd.; product name: Shoumei; quality grade: special grade; net content 600g / bag, aluminum foil packaging, carton outer packaging), crush and sieve to 60 mesh, According to the mass ratio of material to liquid: 1:25, mix with 25L ethanol water solution with a volume fraction of 70%, and extract at room temperature for 3 minutes with a flash method (pilot-type flash extraction apparatus, JHBE-100A, Henan Jinnai Technology Development Co., Ltd.), with a rotation speed of 5000r / min Centrifuge to remove slag (desktop low-speed centrifuge, TD5A-WS, equipped with 851400 horizontal rotor, Xiangyi Centrifuge Instrument Co., Ltd.), 4000r / min (3040xg), collect the centrifuged supernatant, and collect the residue after flash re-extraction once. , the combined supernatant obtained each time is the flash extract;

[0078] (2) Get the filter residue collected in step (1), add 20L of pure water, mix in a 50L stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com