Coalescence principle-based oily-water separating device and method

A technology of oil-water separation device and water distribution device, applied in separation methods, immiscible liquid separation, liquid separation, etc., can solve the problems of single material in packing coalescence zone, no difference in surface free energy, complex structure, etc. Achieve the effect of increasing coalescence rate, improving oil-water separation efficiency, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

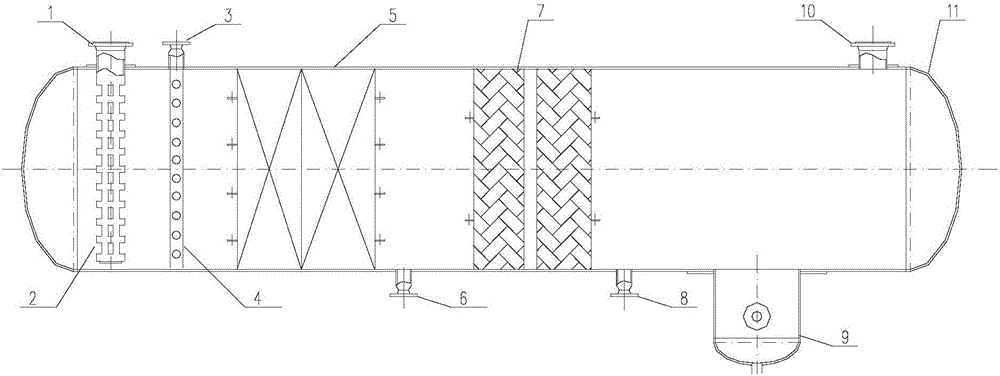

Embodiment 1

[0045] This embodiment provides an oil-water separation device, such as figure 1 As shown, the device is a horizontal structure, including a cylinder 11 and an interface. The top of the cylinder 11 is provided with a raw material liquid inlet 1, and the top of the cylinder 11 is provided with an oil phase outlet on the other side opposite to the raw material liquid inlet 1. 10; In the cylinder 11, a water distribution device 2, a corrugated plate coalescer 5 and a wire mesh coalescer 7 are arranged in sequence from the raw material liquid inlet 1 side; the water distribution device 2 is connected to the raw material liquid inlet 1, and the bottom of the cylinder 11 is There is a primary sewage outlet 6 between the corrugated plate coalescer 5 and the wire mesh coalescer 7, and the bottom of the cylinder 11 is provided with a water phase outlet 9 on the side opposite to the raw material liquid inlet 1. The bottom of the cylinder 11 is coalesced on the wire mesh A secondary sewag...

Embodiment 2

[0051] This embodiment provides an oil-water separation device. The device is a horizontal structure and includes a cylinder body and an interface 11. The top side of the cylinder body 11 is provided with a raw material liquid inlet 1, and the top of the cylinder body 11 is opposite to the raw material liquid inlet 1. The other side is provided with an oil phase outlet 10; in the cylinder 11, a corrugated plate coalescer 5 and a wire mesh coalescer 7 are arranged in sequence from the raw material liquid inlet 1 side; the bottom of the cylinder 11 is located at the corrugated plate coalescer 5 and silk Between the mesh coalescer 7 is provided a first-level sewage outlet 6, the bottom of the cylinder 11 is provided with a water phase outlet 9 on the side opposite to the raw material liquid inlet 1, and the bottom of the cylinder 11 is located between the wire mesh coalescer 7 and the water outlet 9 There is a secondary sewage outlet 8;

[0052] Wherein, the wire mesh coalescer 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com