Efficient beneficiation method of pyrite in lead-zinc flotation tailings

A technology for flotation tailings and beneficiation methods, applied in flotation, solid separation and other directions, can solve the problems of high beneficiation cost, high consumption of chemicals, low selected concentration, etc., and achieves wide popularization and application prospects, reduced dosage, and efficient separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

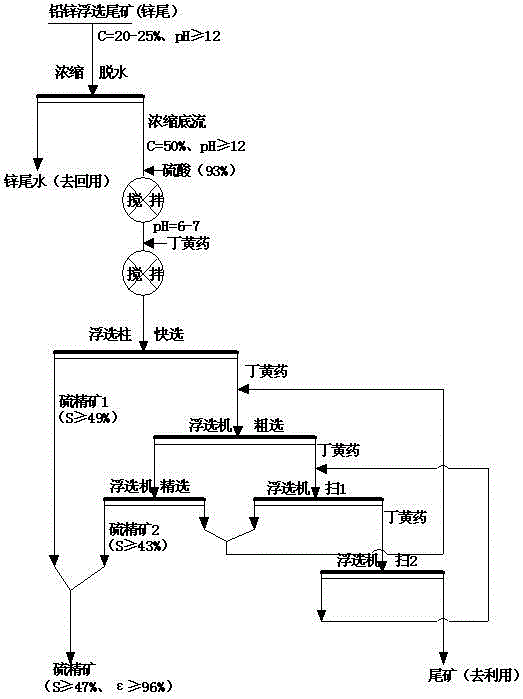

Image

Examples

Embodiment Construction

[0012] A lead-zinc mine is rich in co-associated pyrite resources, which is a typical lead-zinc polymetallic mine. Sulfur flotation machines have many problems such as high energy consumption, high reagent consumption, and frequent overflow of sulfur selection. Moreover, with the demand for sulfur grades in the sulfur iron market, product sales are facing difficulties, and economic benefits have been greatly affected. Traditional sulfur selection technology can no longer meet the requirements. The normal production demand of the market and mines. After carrying out the systematic research on the technology of this project, the results have been put into application one after another and after continuous improvement, the recovery rate of the beneficiation operation of sulfur in the lead-zinc flotation tailings has increased by 11 percentage points; the main grade of sulfur concentrate has increased by 9 percentage points ; The power consumption of sulfur selection is reduced by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com