Method for Determining the Position of Rollers in Three-point Bending Flexible Cold Forming of Longitudinal Welded Pipes

A flexible forming and three-point bending technology, applied in instruments, manufacturing tools, design optimization/simulation, etc., can solve the problems of cumbersome determination methods, difficult welding pipe forming, and large test workload, and achieve multi-specification automatic adjustment and flexible production. , The effect of ensuring the accuracy of welded pipe forming and reducing the waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

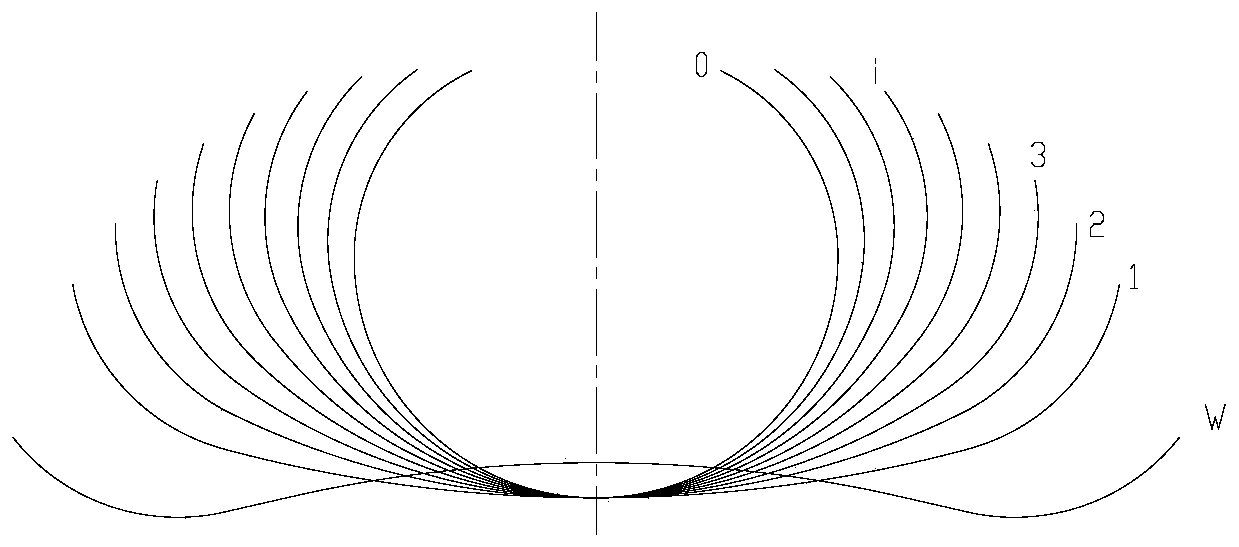

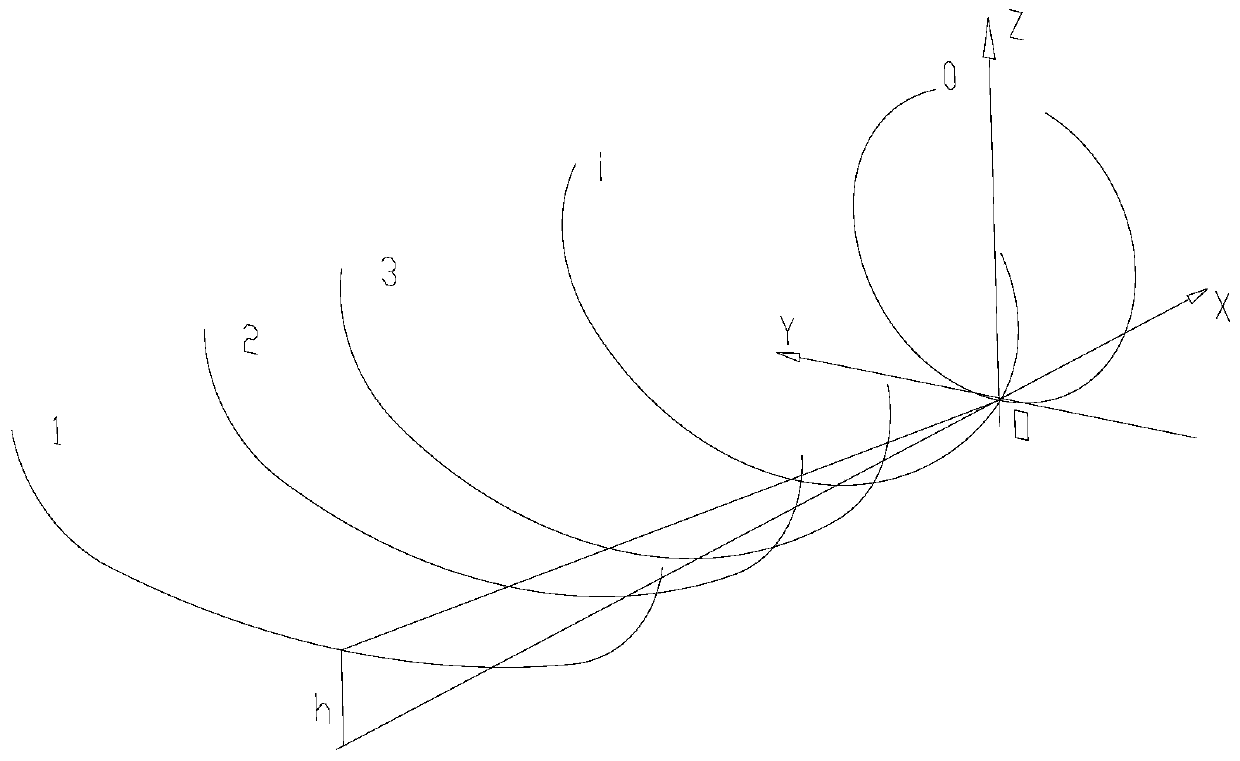

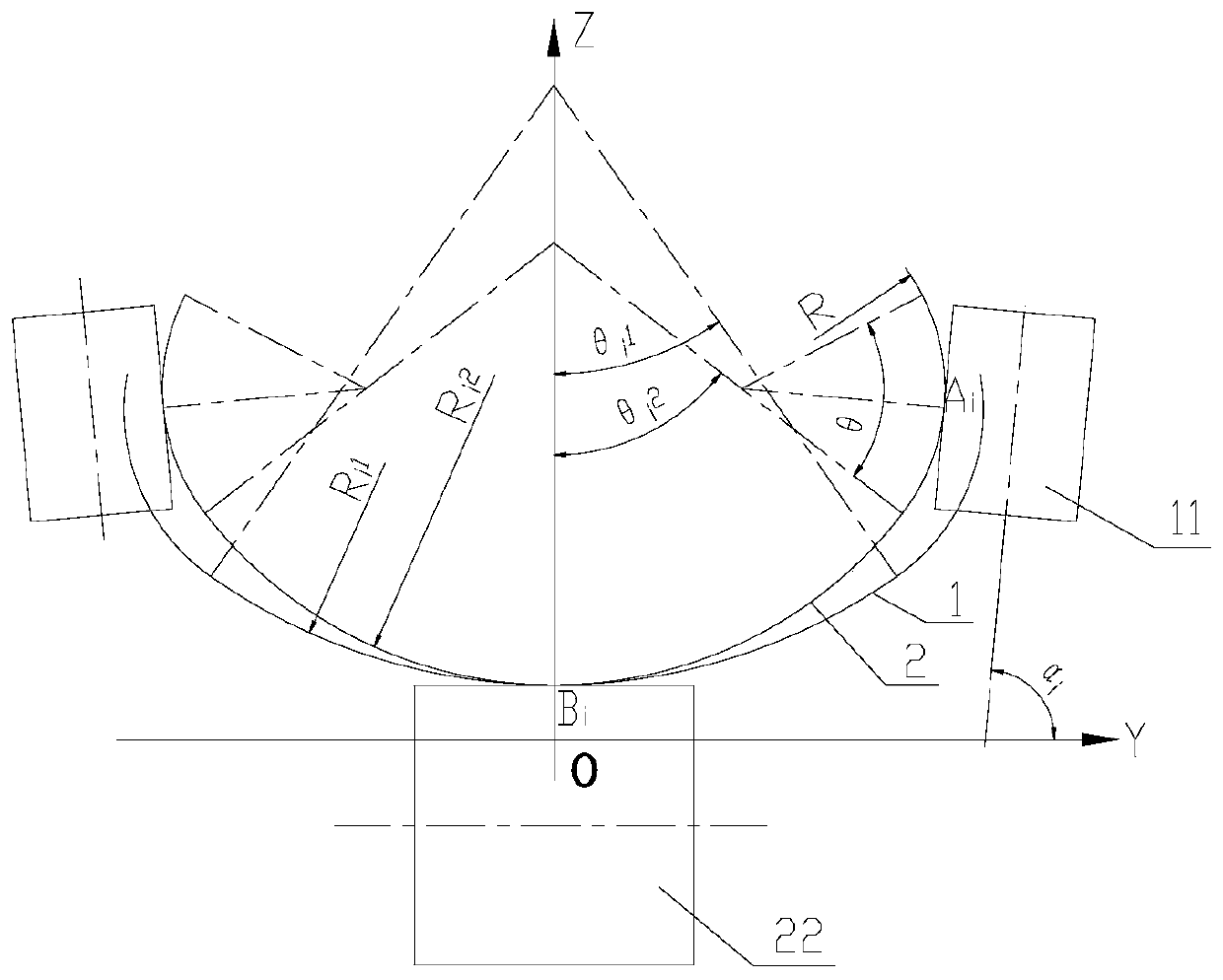

[0041] In the present invention, there are 9 flexible frames after preforming by a flexible forming unit W, and low-carbon steel pipes of Φ80×2mm are formed on the forming frames. ,Such as figure 1 , W preformed both sides of the arc radius R = 42.82mm, top angle θ = 65 °, low carbon steel yield strength σ s =240MPa, modulus of elasticity E=210000MPa, coefficient of springback H=σ s / E=0.00114; the first and second of the nine frames are flexible forming frames with horizontal rollers, and the inclination angle of the forming side mold rollers ω 1 =32°, ω 2 =48°, the minimum forming pipe diameter of this production line is 40mm. In fact, the radius of the die roll transition arc is small, and the contact angle can take a larger value when forming an 80mm pipe without interference. The rest are flexible forming frames for side rolls. The total downhill amount h=40mm, the distance between the centers of each flexible forming frame is equal, both are 410mm, the calculated down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com