Phosphate inorganic binder based on lactic acid and polylactic acid modification and preparation method thereof

A technology of inorganic binder and polylactic acid, which is used in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as poor stability, poor hygroscopicity, and reduced strength, and achieve low cost, good collapsibility, and improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

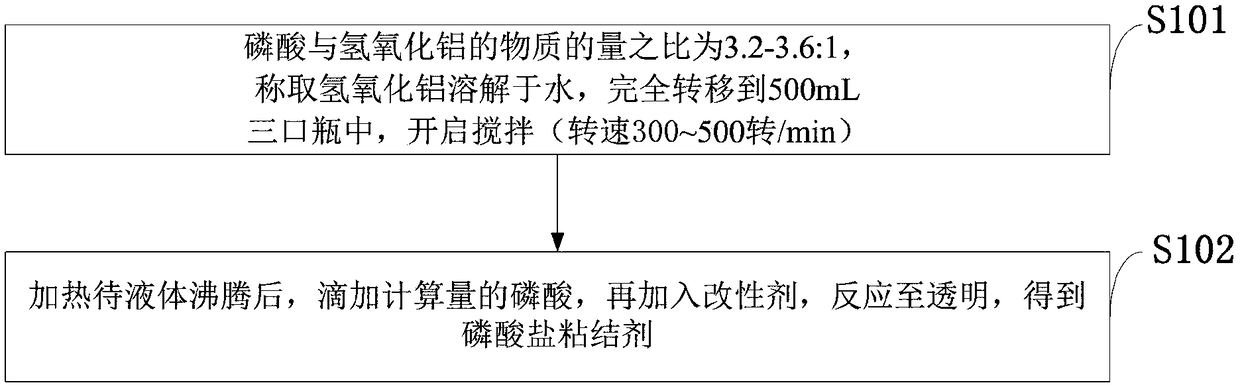

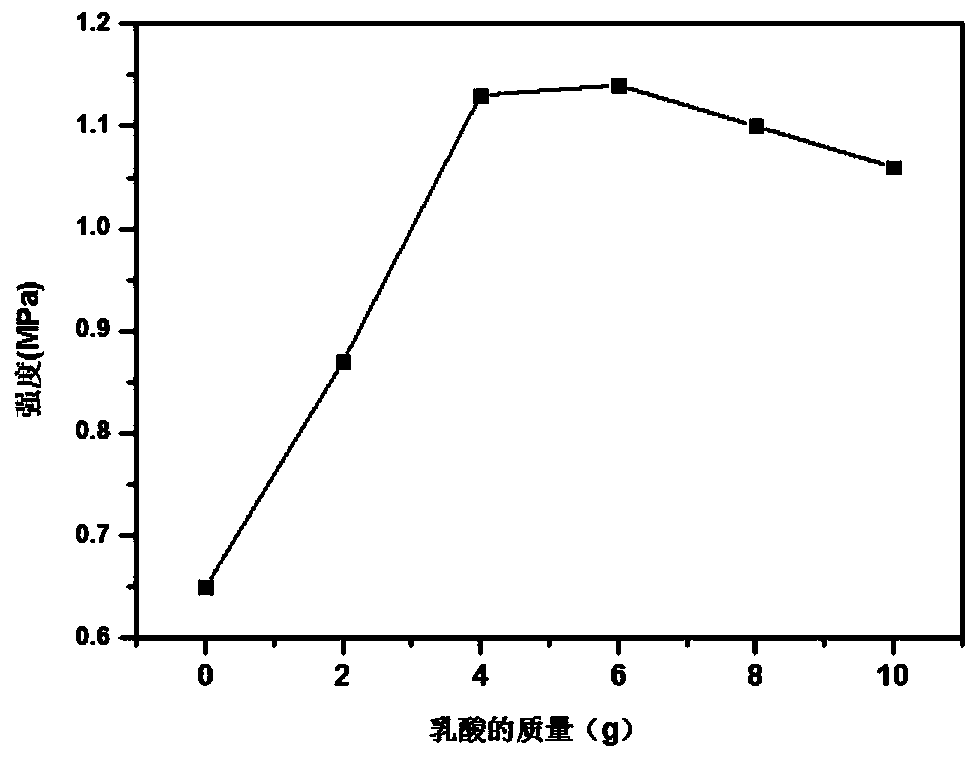

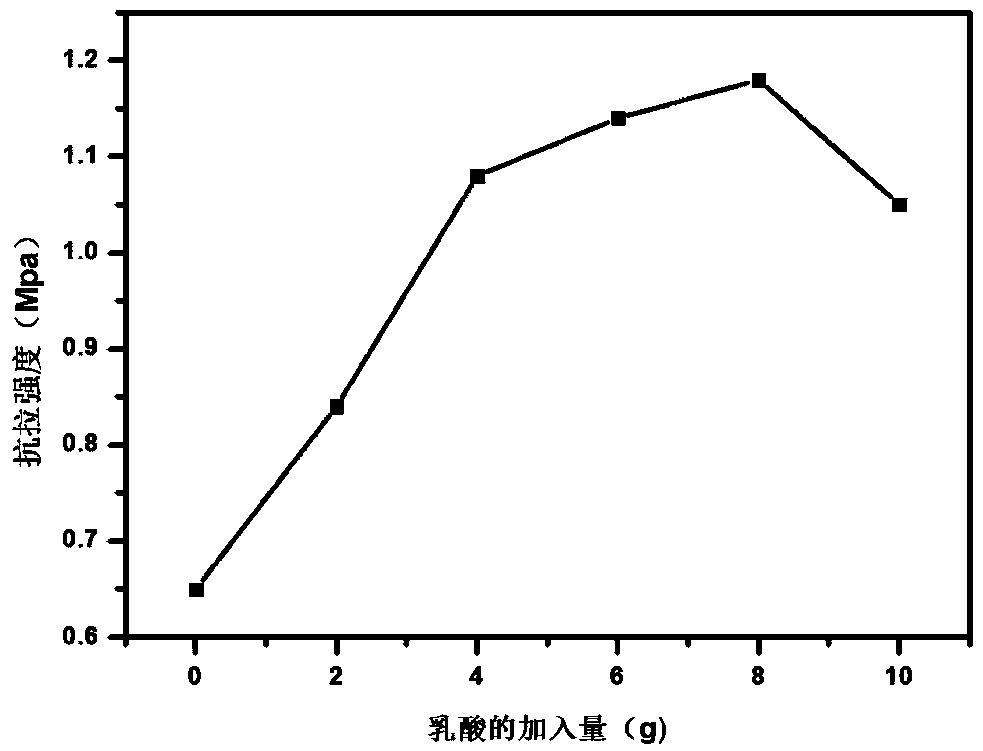

[0023] The best process of the embodiment of the present invention is: the neutralization degree of the phosphate inorganic binder based on lactic acid and polylactic acid modification is 3.2-3.6, 100mL binder is added with modifier lactic acid or polylactic acid 4.0-10.0g, mixed Add 5.0-10.0g of solidifying agent metal oxide to the sand process, and the ratio of phosphoric acid to aluminum hydroxide is 3.2-3.6:1, and the strength of the molding sand with modified phosphate binder is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com