Vertical movement inverted-hung type mechanical arm installation platform

A technology of installation platform and vertical motion, applied in the direction of manipulator, program-controlled manipulator, manufacturing tool, etc., can solve the problem that the base space cannot be used as a working space, etc., to improve the applicability and practicability, efficiency and high efficiency, and the overall structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

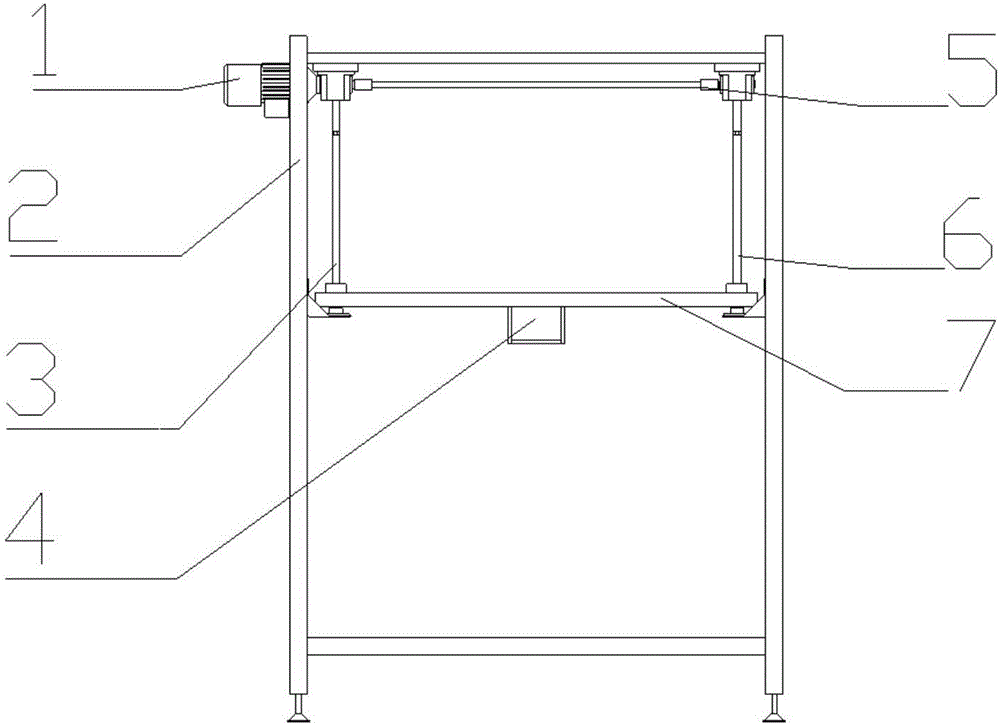

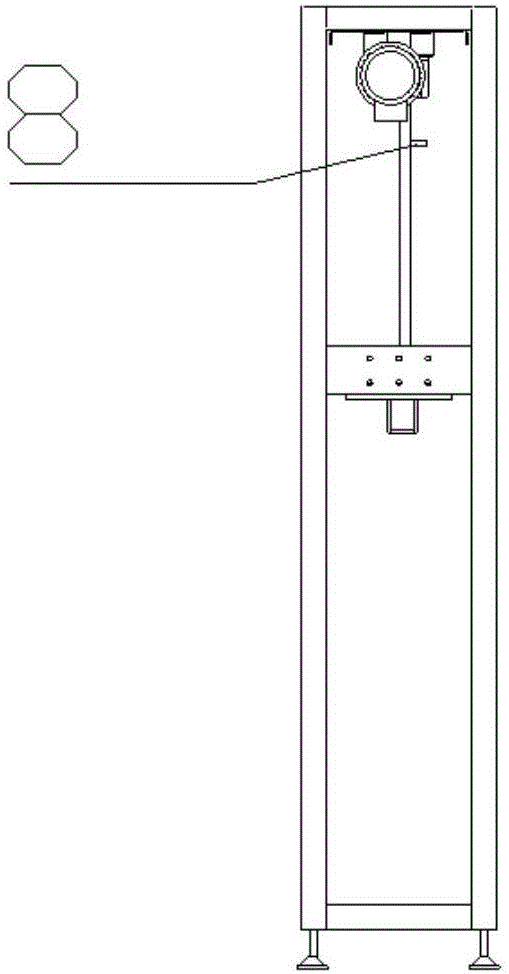

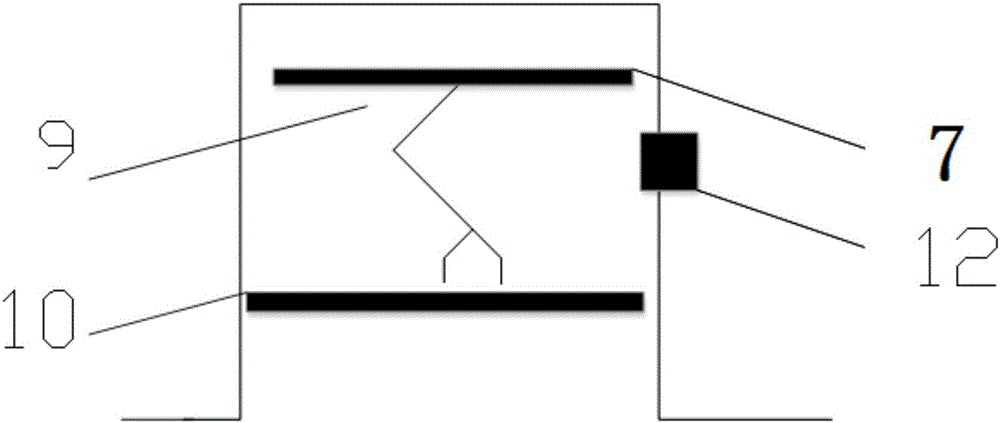

[0023] The invention provides a vertically moving upside-down mechanical arm installation platform, such as figure 1 As shown, the robotic arm installation platform includes a frame 2, a drive motor and a reducer 1, a polished rod 5, a lead screw I3, a lead screw II 6, a robotic arm base 4 and a base 7, and the peripheral device is a mechanical arm 9.

[0024] The present invention adopts forging process to manufacture frame 2 and mechanical arm base 4, and manufactures polished rod 5 with lathe process, frame 2 material, type of drive motor etc. are all designed according to the standard.

[0025] The driving motor and the reducer 1 are installed on the frame 2, and the driving motor transmits the torque to the polished rod 5 after being decelerated by the reducer. The two ends of the polished rod 5 are connected to the top ends of the lead screw I3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com