Interlaminar reinforcement continuous fiber composite material additive manufacturing method

A continuous fiber and composite material technology, applied in additive manufacturing, processing manufacturing, manufacturing tools, etc., can solve the problems of imperfect additive manufacturing method and low interlayer strength of composite materials, achieve high level of equipment automation, and increase fiber volume Score, controllable effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

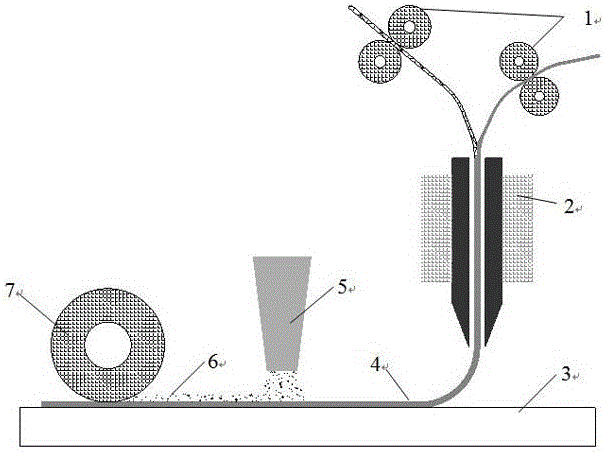

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] The specific steps of the interlayer reinforced continuous fiber reinforced composite material additive manufacturing method of the present invention are as follows:

[0033] A. Establish the CAD model of the continuous fiber reinforced composite parts;

[0034] B. According to the CAD model, the ratio data of continuous carbon fiber and ABS resin, model contour data and scanning path data of the workpiece are obtained;

[0035] C. Select T300 type 1K carbon fiber and ABS resin wire to arrange on the wire drawing mechanism;

[0036] D. The selected carbon fiber and ABS filament are drawn into the printing nozzle by the wire drawing mechanism, and extruded from the nozzle through melt extrusion;

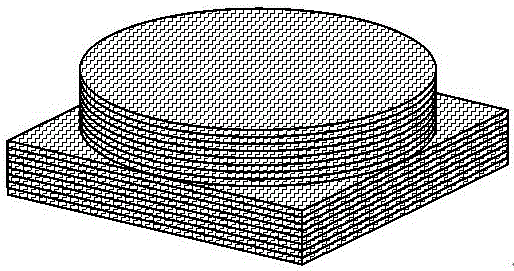

[0037] E. According to the model outline data and scanning path data of the workpiece, the print nozzle is controlled by CAD drive to print carbon fiber / ABS composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com