Suspension frame carrying arm structure of middle-low-speed magnetic suspension vehicle

A suspension frame and support arm technology, which is applied to vehicle components, electric vehicles, electric traction, etc., can solve problems such as high manufacturing precision requirements, insufficient structural stability, and large intervals between adjacent motors, so as to reduce maintenance costs and weaken the terminal. The effect of the internal effect and the elimination of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

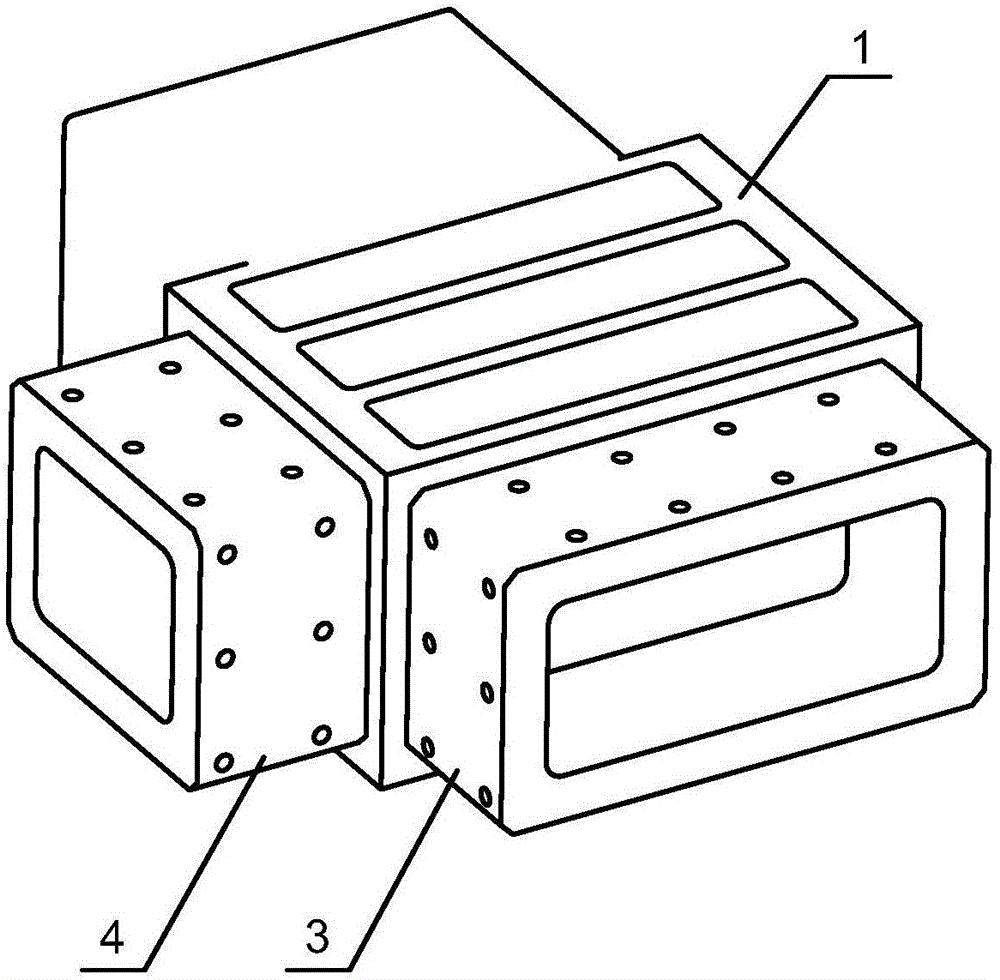

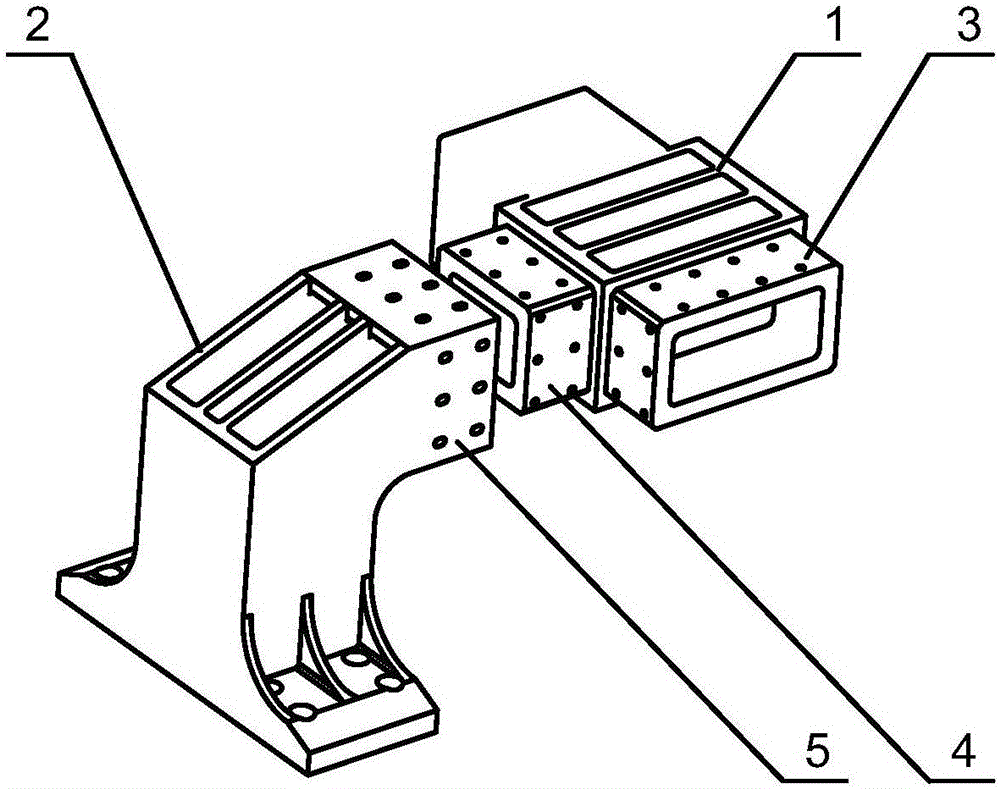

[0019] Embodiment 1, such as figure 1 As shown, a support arm structure for the suspension frame of a medium-low speed maglev vehicle, its main function is to provide the installation foundation for the suspension electromagnet, and the suspension electromagnet is attracted to the track to make the vehicle suspend. The support arm structure of the low-speed maglev vehicle suspension frame mainly includes the support arm upper part 1 and the support arm lower part 2. The mortise and holes of the parts are fitted through tenon joints and fastened with bolts. The upper part 1 of the bracket arm is provided with a first boss structure 4 as a tenon on the side close to the second boss structure 3, and the upper part 1 of the bracket arm and the mortise hole of the horizontal end 5 of the lower part 2 of the bracket arm are fitted through tenon joints and tightened with bolts. solid.

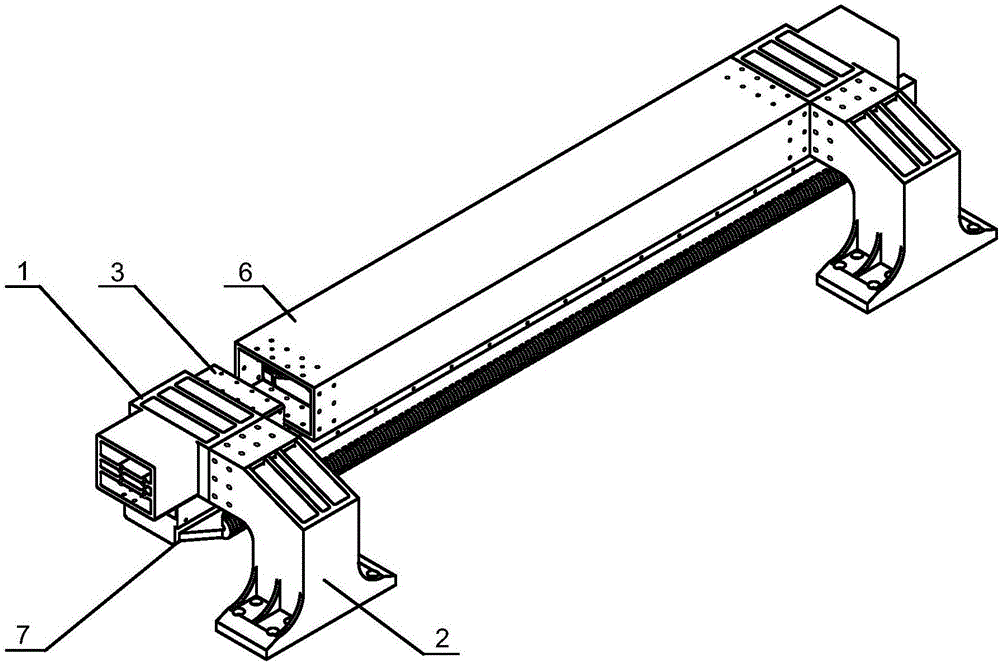

[0020] Such as figure 2 , 3 As shown, the upper part 1 of the support arm is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com