Distributed propulsion system

A propulsion system and distributed technology, applied in the field of aviation propulsion systems, can solve problems such as unfavorable aircraft layout, heavy weight, complex mechanical transmission mechanism, etc., and achieve the effect of improving realizability, large bypass ratio, and high system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

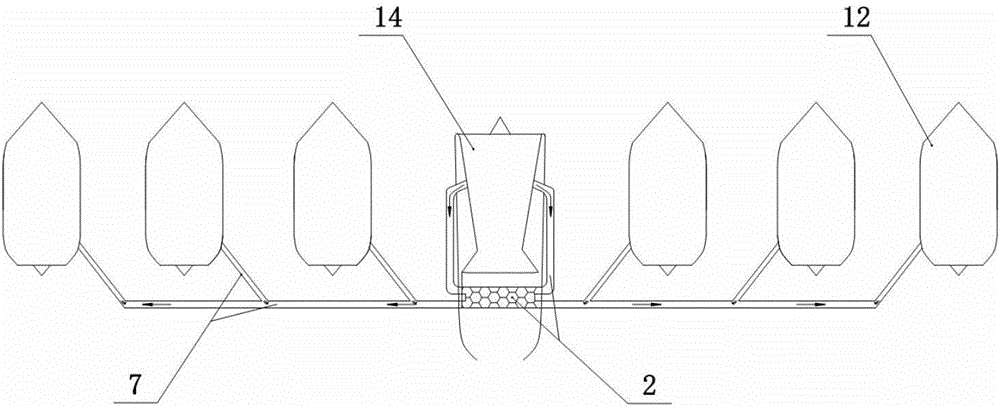

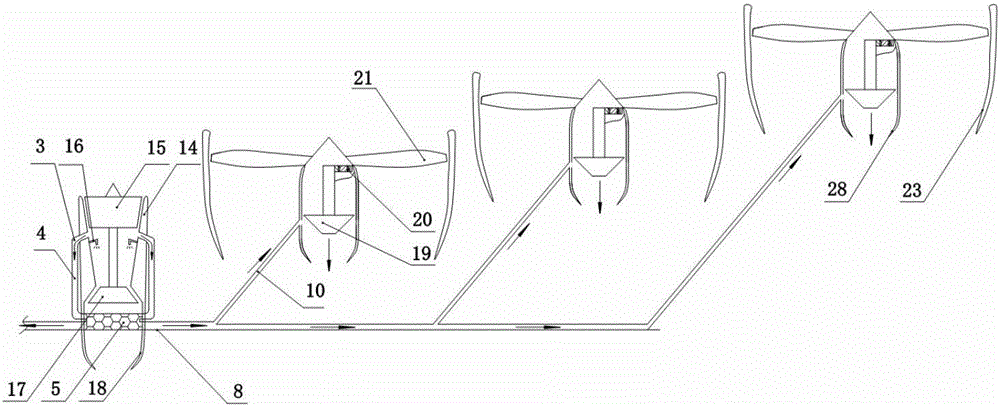

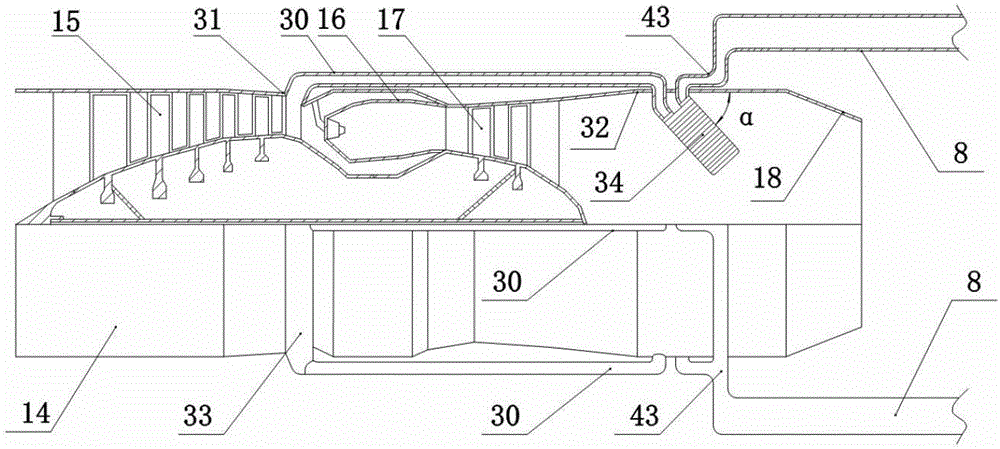

[0049] This embodiment is a distributed propulsion system based on working medium transmission.

[0050] This embodiment includes a turbine engine core machine 14 , a high-efficiency working medium transmission device 7 , a high-energy working medium collection device 2 and a distributed propeller 12 . The input end of the gas collection device 3 of the high-energy working medium collection device 2 communicates with the output end of the core machine compressor 15 of the turbine engine core machine; the output end of the high-energy working medium collection device 2 communicates with the high-efficiency working medium transmission device 7 import connections. The output end of the transmission branch pipe 10 in the high-efficiency working medium transmission device 7 communicates with the input end of the propeller turbine volute 45 of each distributed propeller 12 respectively; The transfer manifold 8 in the device 7 communicates. In this embodiment, there are six distrib...

Embodiment 2

[0070] This embodiment is a distributed propulsion system based on working medium transmission.

[0071] Embodiment 2 differs from Embodiment 1 in that the gas turbine engine core machine 14 in Embodiment 2 is a twin-rotor turbojet engine. All the other parts are the same as in Example 1.

[0072] This embodiment includes a turbine engine core machine 14 , a high-efficiency working medium transmission device 7 , a high-energy working medium collection device 2 and a distributed propeller 12 . The input end of the gas collection device 3 of the high-energy working medium collection device 2 communicates with the output end of the high-pressure compressor 6 of the turbine engine core machine; connected. The output end of the transmission branch pipe 10 in the high-efficiency working medium transmission device 7 communicates with the input end of the propeller turbine volute 45 of each distributed propeller 12 respectively; The transfer manifold 8 in the device 7 communicates....

Embodiment 3

[0076] This embodiment is a distributed propulsion system based on working medium transmission.

[0077] The difference between embodiment 3 and embodiment 1 is that the fan 21 in embodiment 1 is replaced by propeller 22 in embodiment 3. All the other parts are the same as in Example 1.

[0078] This embodiment includes a turbine engine core machine 14 , a high-efficiency working medium transmission device 7 , a high-energy working medium collection device 2 and a distributed propeller 12 . The input end of the gas collection device 3 of the high-energy working medium collection device 2 communicates with the output end of the high-pressure compressor 6 of the turbine engine core machine; connected. The output end of the transmission branch pipe 10 in the high-efficiency working medium transmission device 7 communicates with the input end of the propeller turbine volute 45 of each distributed propeller 12 respectively; The transfer manifold 8 in the device 7 communicates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com