Tension control system

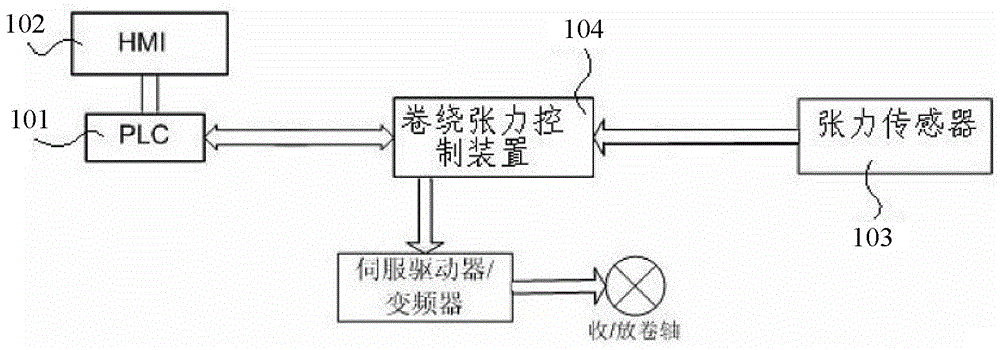

A technology of tension control and tension controller, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems that the control method is not flexible enough, not perfect and convenient, and does not involve tension partition, etc., to achieve Easy operation, flexible control and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. It should be understood by those skilled in the art that these descriptions only illustrate exemplary embodiments of the present invention, and are not intended to limit the protection scope of the present invention. For example, elements or features described in one figure or embodiment of the invention may be combined with other elements or features shown in one or more other figures or embodiments.

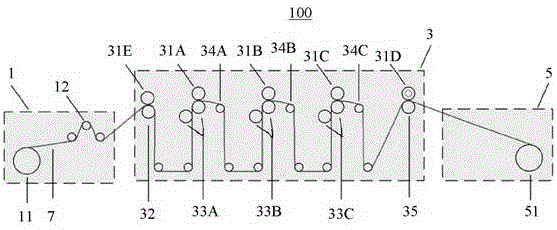

[0038] Please refer to figure 2 , which shows a schematic diagram of an electroplating apparatus 100 according to an embodiment of the present invention. The electroplating device 100 mainly includes an unwinding section 1 , an electroplating section 3 and a winding section 5 . The unwinding section 1 includes an unwinding shaft 11 and an unwinding tension sensor 12, and the unwinding shaft 11 can be connected with an unwinding servo motor. The electroplating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com