Water treatment method for catalyzing persulfate with tube wall corrosive to intensify sterilization of liquid chlorine/chloramines

A persulfate and chloramine disinfection technology, applied in the field of water treatment, can solve the problems of secondary reproduction of microorganisms and incomplete inactivation of microorganisms, and achieve the effects of ensuring biological stability, preventing secondary reproduction, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment 1: This embodiment is a water treatment method that utilizes persulfate to catalyze persulfate-enhanced disinfection of liquid chlorine / chloramine by pipe wall corrosives, which is realized by the following steps: adding liquid chlorine or When the chloramine is disinfected, the persulfate solution is added at the same time, and the stirring state is maintained to complete the water treatment method that uses the corrosive substance on the pipe wall to catalyze the persulfate to enhance the disinfection of liquid chlorine / chloramine. The concentration is 1-100mg / L.

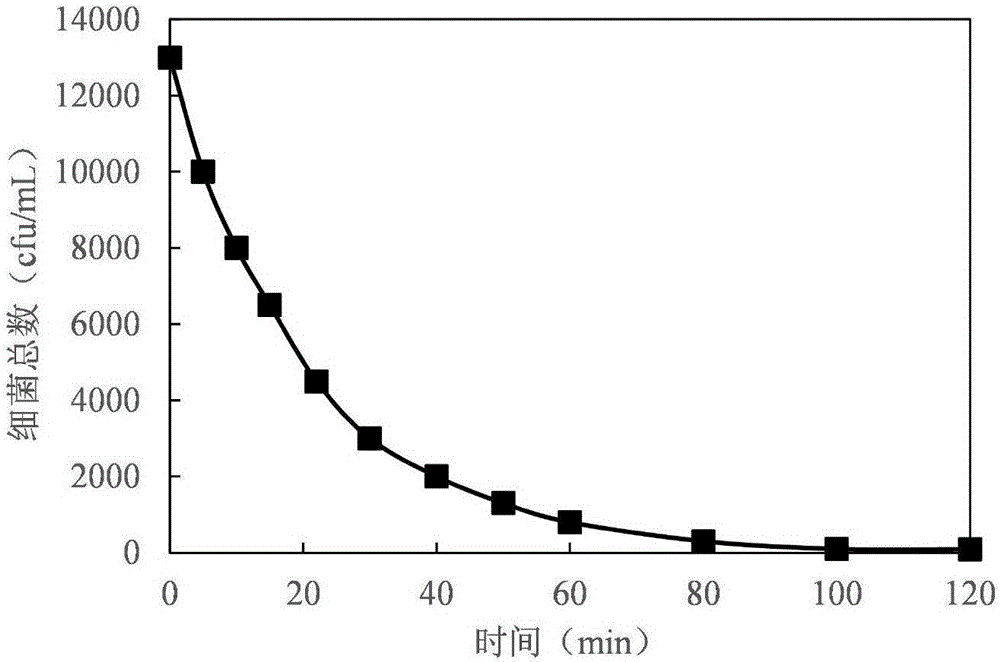

[0014] The principle of this embodiment is a water treatment method that uses pipe wall corrosives to catalyze persulfate to enhance liquid chlorine / chloramine disinfection: the persulfate on the pipe wall corrodes (iron, copper, manganese, zinc and other metal oxides) Sulfate free radicals are produced under catalysis. Sulfate free radicals use their strong oxidizing properties to inactiva...

specific Embodiment approach 2

[0016] Specific embodiment two: This embodiment is different from the specific embodiment one in that the concentration of persulfate in the water to be treated is 1.5-90 mg / L. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the concentration of persulfate in the water to be treated is 2 to 80 mg / L. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com