A kind of cell-like multiphase emulsion photoenzyme system catalyzes the method of oil hydrolysis and decarboxylation

A technology of multiphase emulsion and enzyme system, applied in the direction of fermentation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

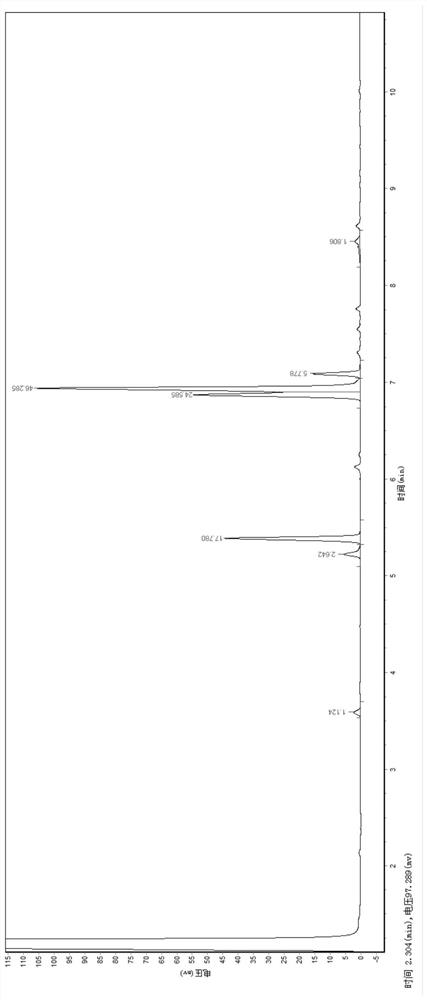

[0050] Take 0.05g lipase AYS and place in a transparent glass bottle, 0.24g dipotassium hydrogen phosphate, 1mL (0.975g) Tris-HCl (100mM, pH=8.5) solution, mix well, add 1.5mL (about 0.6g) large intestine Bacteria whole cells (containing CvFAP) were mixed evenly, and 0.233g of polyethylene glycol 400 and 0.05g of waste cooking oil were added, put into a interlayer beaker wrapped with an LED light device capable of producing blue light, and placed at a constant temperature of 1000rpm On the stirrer, the reaction was controlled at 30°C for 12h. After the reaction, add ethyl acetate twice the volume of the system for extraction, set 12000rpm to centrifuge for 3 minutes, and divide into three layers, which are the upper liquid layer, middle liquid layer and lower liquid layer in turn. After hydrolysis, free fatty acids and long Paraffins and unreacted esters are mainly enriched in the upper liquid layer, and the upper liquid layer product is collected as the product, and the resul...

Embodiment 2

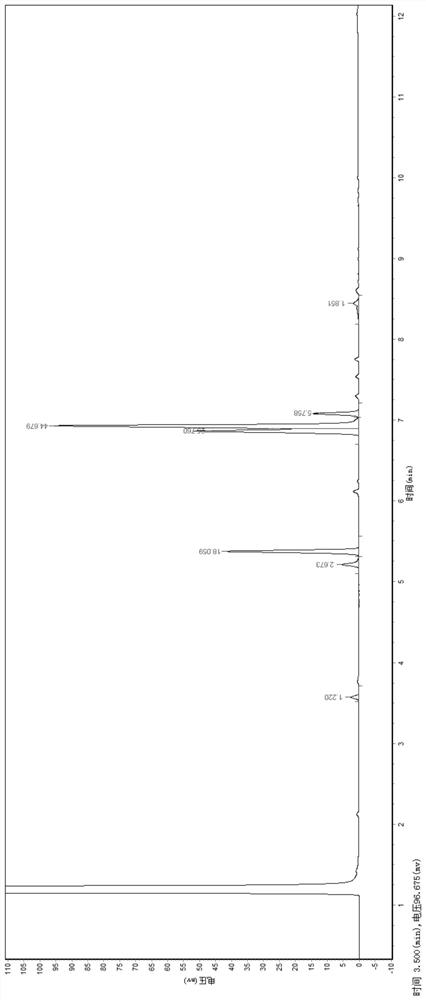

[0053] Take 0.05g lipase AYS and place in a transparent glass bottle, 0.30g sodium sulfate, 1mL (0.975g) Tris-HCl (100mM, pH=8.5) solution, mix well, add 1.5mL (about 0.6g) whole Escherichia coli Cells (containing CvFAP) were mixed evenly, added 0.279g polyethylene glycol 600 and 0.05g camellia oil, put into a sandwich beaker wrapped with an LED light device capable of producing blue light, and placed on a constant temperature stirrer with a rotation speed of 1000rpm , Control the reaction at 30°C for 12h. After the reaction, add ethyl acetate twice the volume of the system for extraction, set 12000rpm to centrifuge for 3 minutes, and divide into three layers, which are the upper liquid layer, middle liquid layer and lower liquid layer in turn. After hydrolysis, free fatty acids and long Paraffins and unreacted esters are mainly enriched in the upper liquid layer, and the upper liquid layer product is collected as the product, and the resulting product is determined by GC ( ...

Embodiment 3

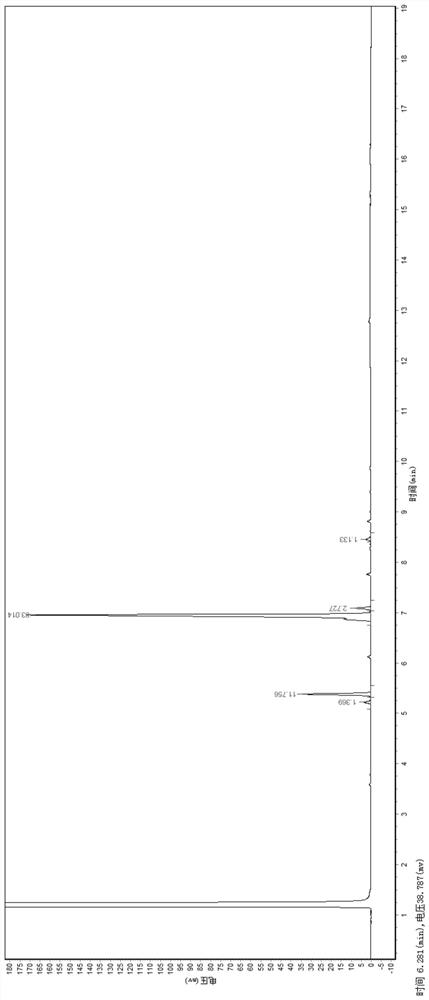

[0056] Take 0.05g lipase AYS and place in a transparent glass bottle, 0.24g dipotassium hydrogen phosphate, 1mL (0.975g) Tris-HCl (100mM, pH=8.5) solution, mix well, add 1.5mL (about 0.6g) large intestine Bacillus whole cells (containing CvFAP) were mixed evenly, added 0.285g polyethylene glycol 400, 0.05g soybean oil, put into a sandwich beaker wrapped with an LED light device capable of producing blue light, and placed in a constant temperature stirring at a speed of 1000rpm On the device, the reaction was controlled at 30°C for 12h. After the reaction, add ethyl acetate twice the volume of the system for extraction, set 12000rpm to centrifuge for 3 minutes, and divide into three layers, which are the upper liquid layer, the middle liquid layer and the lower liquid layer in turn. After hydrolysis, free fatty acids and long Paraffins and esters that have not participated in the reaction are mainly enriched in the upper liquid layer, and the product of the upper liquid layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com