A biostable metalworking fluid without bactericide and its preparation method

A metalworking fluid and bio-stabilization technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of operators and environmental impacts, and achieve the effect of not being easy to be corrupted, not easy to delaminate and demulsify, and the working environment is safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

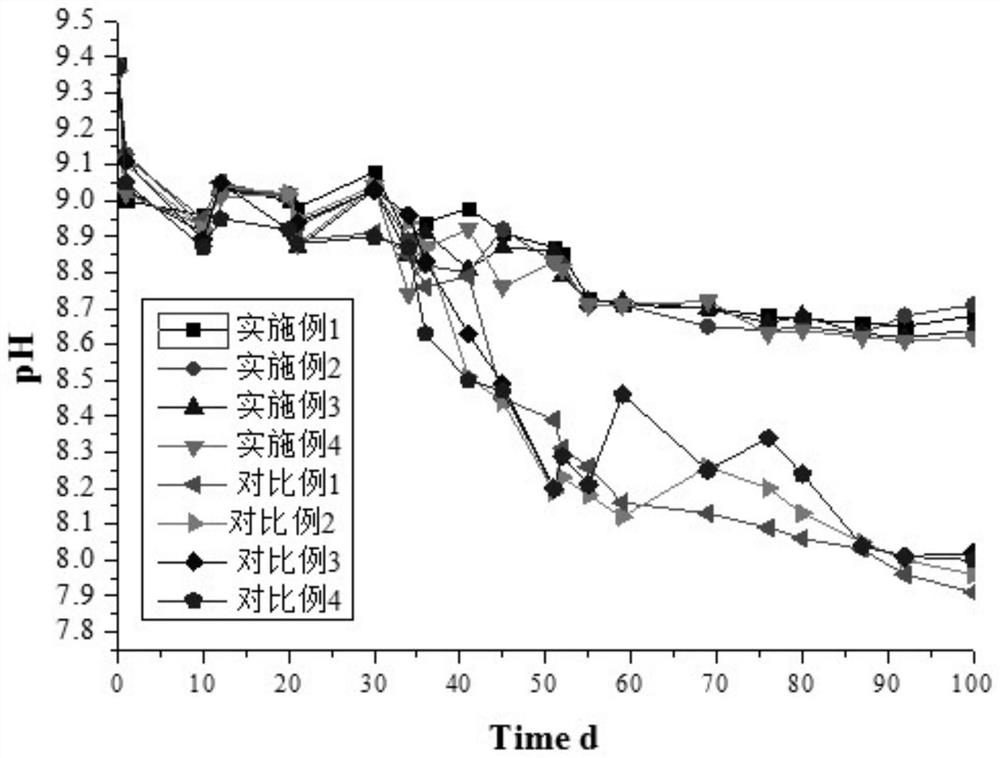

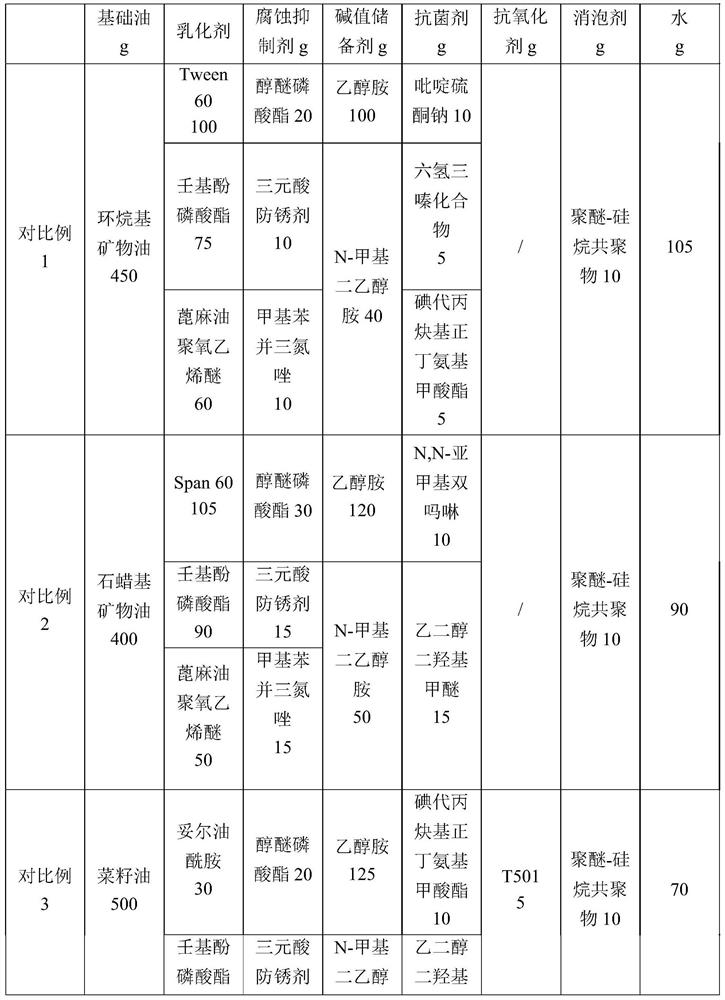

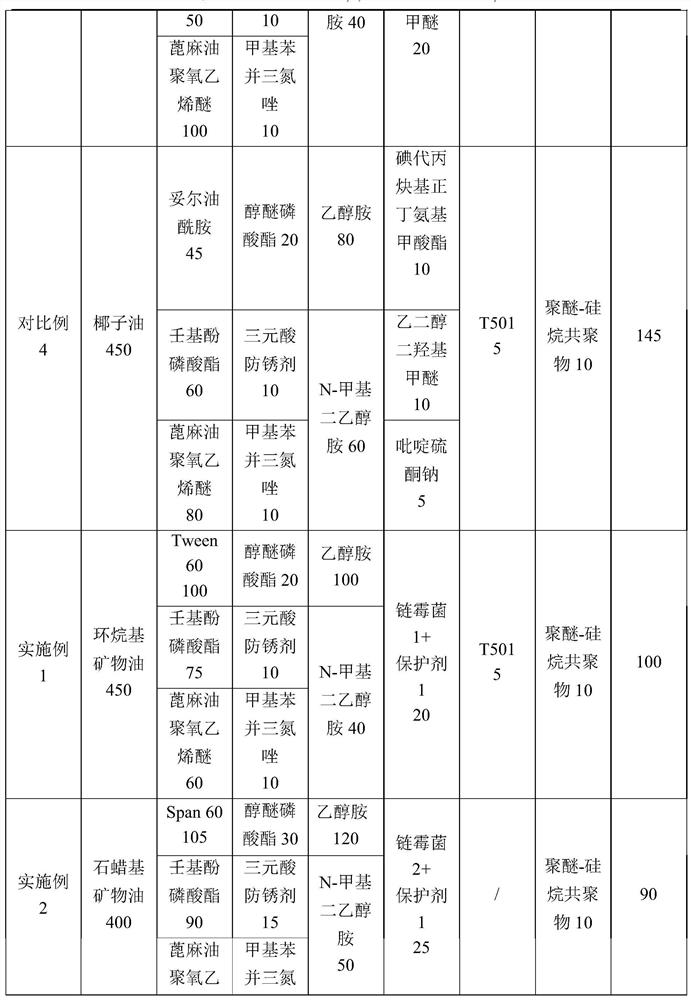

[0066] Using the above-mentioned preparation method of the processing fluid, the processing fluids of Comparative Example 1, Comparative Example 2, Comparative Example 3, Comparative Example 4 and Example 1, Example 2, Example 3, and Example 4 were respectively prepared according to Table 1.

[0067] Table 1 Example 1-4 and comparative example 1-4 processing fluid composition list

[0068]

[0069]

[0070]

Embodiment 1

[0073] Embodiment 1: first get the activated Streptomyces 1 and inoculate it into an appropriate amount of Streptomyces 1 liquid medium, expand and cultivate it for 1 day at 30°C, and obtain the seed culture solution through two times of expansion cultivation; the seed culture solution is inoculated with an appropriate amount of Inoculate a large amount of bacteria into the enrichment medium, shake and culture at 30°C for 1 day to obtain the bacterial liquid; then centrifuge the collected bacterial liquid, discard the supernatant, wash the precipitated bacterial cells with 0.9% sterile normal saline, and then Centrifuge, discard the supernatant, and the obtained precipitate is the Streptomyces 1 cell; then fully dry the Streptomyces 1 cell at about 30°C to obtain the powder Streptomyces 1 cell; After the protective agent 1 is fully mixed, it is filtered to obtain a spore suspension, which is a biologically stable preparation. Wherein, the pH of Streptomyces 1 liquid culture me...

Embodiment 2

[0074] Embodiment 2: first get the activated Streptomyces 2 and inoculate it into an appropriate amount of Streptomyces 2 liquid culture medium, expand and cultivate it at 30°C for 2 days, and obtain the seed culture solution through two expansion cultures; the seed culture solution is inoculated with an appropriate amount of Inoculate a large amount of bacteria in the enrichment medium, shake and culture at 30°C for 2 days to obtain the bacterial liquid; then centrifuge the collected bacterial liquid, discard the supernatant, wash the precipitated bacterial cells with 0.9% sterile normal saline, and then Centrifuge, discard the supernatant, and the obtained precipitate is the Streptomyces 2 cells; then fully dry the Streptomyces 2 cells at about 30°C to obtain the powder Streptomyces 2 cells; finally mix the powder and the cells After the protective agent 1 is fully mixed, it is filtered to obtain a spore suspension, which is a biologically stable preparation. Wherein, the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com