Method for treating drinking water of replacing disinfecting action of medicament

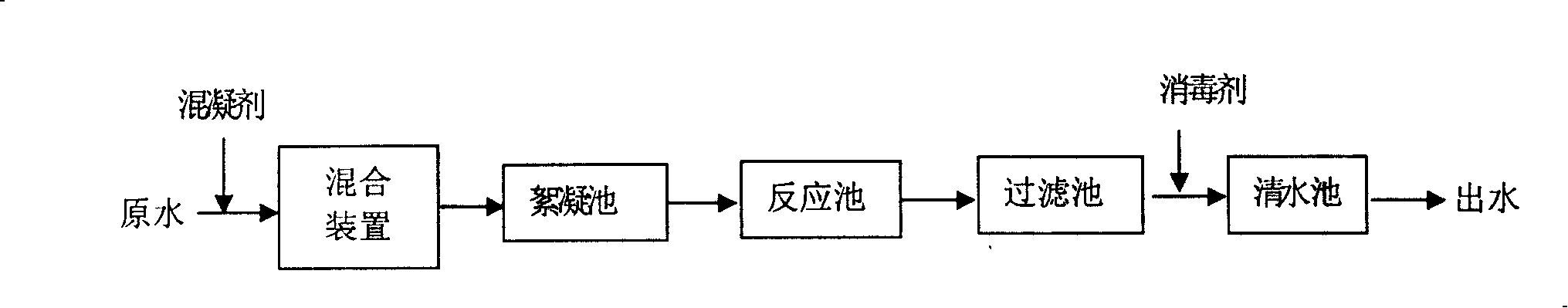

A technology for drinking water treatment and chemical disinfection, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmotic/dialysis water/sewage treatment, etc. Oxygen bacteria re-growth, costing money and other problems, to achieve the effect of eliminating the disinfection link, reducing the amount of production, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

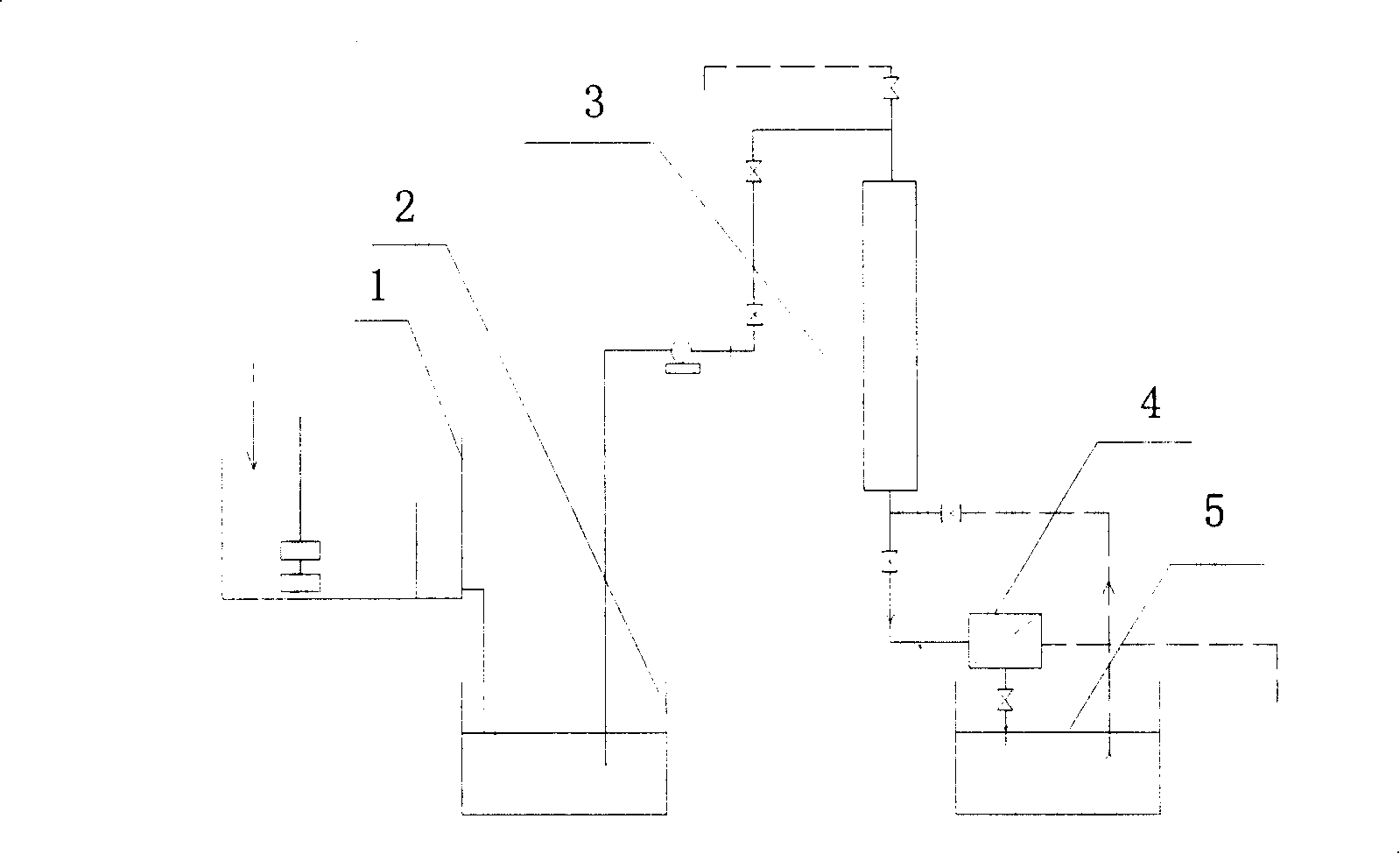

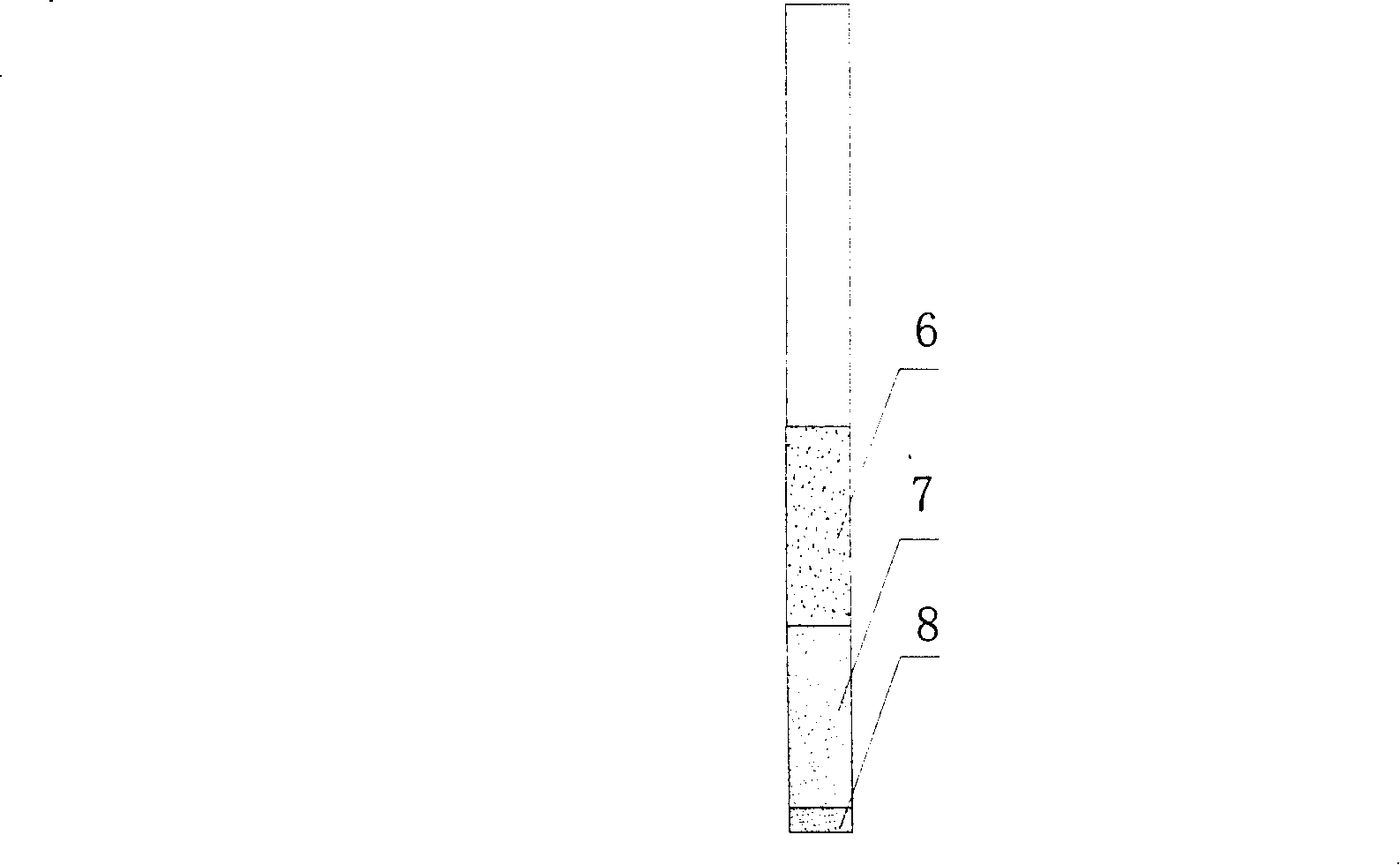

Embodiment 1

[0028] In this example, the total phosphorus in the raw water is 64ug / L, the bioavailable phosphorus (MAP) is 3.8ug / L, and the total number of bacteria is 2.3×10 5 individual / mL, total coliform bacteria 1.8×10 7 A / L, turbidity 12.5NTU. Under the condition of sufficient stirring, pump 7 mg / L of composite high-efficiency flocculant (see attached table 1) to fully mix with the raw water, and the residence time is 30 seconds; complete the physical and chemical processes such as flocculation, adsorption, and co-sedimentation in the flocculation reactor 2, The stay time is 20 minutes. Afterwards, the upper layer is activated alumina filter layer 6 with a thickness of 500mm, the middle layer is a quartz sand filter layer 7 with a thickness of 1000mm, and the lower layer is a composite filter column 3 with a support layer 8 with a thickness of 400mm for filtration. The filtration speed is 6m / h. The filtered water is filtered by the ultrafiltration membrane filter 5, and the membra...

Embodiment 2

[0030] In this example, the total phosphorus in the raw water is 96ug / L, the bioavailable phosphorus (MAP) is 5.3ug / L, and the total number of bacteria is 7.8×10 4 individual / mL, total coliform bacteria 2.6×10 6 A / L, turbidity 10NTU. Under full stirring, pump 8 mg / L of composite high-efficiency flocculant (see attached table 1) to fully mix with raw water, and the residence time is 40 seconds; the physical and chemical processes such as flocculation, adsorption, co-sedimentation, etc. 15 marks. Afterwards, the upper layer is activated alumina filter layer 6 with a thickness of 800mm, the middle layer is a quartz sand filter layer 7 with a thickness of 1000mm, and the lower layer is a composite filter column 3 with a supporting layer 8 with a thickness of 400mm for filtration, and the filtration speed is 6m / h. The filtered water is filtered by the ultrafiltration membrane filter 5, and the membrane filtered water is tested, the total phosphorus is 0.8ug / L, the bioavailable ...

Embodiment 3

[0032] In this example, the total phosphorus in the raw water is 112ug / L, the bioavailable phosphorus (MAP) is 4.3ug / L, and the total number of bacteria is 4.5×10 5 individual / mL, total coliform bacteria 6.8×10 6 A / L, turbidity 12NTU. Under full stirring, pump 10 mg / L of composite high-efficiency flocculant (see attached table 1 for composition) and fully mix with raw water, and the residence time is 35 seconds; the physical and chemical processes such as flocculation, adsorption, and co-sedimentation are completed in the flocculation reactor 2, and the residence time 25 points. Afterwards, the upper layer is an activated alumina filter layer 6 with a thickness of 1000mm, the middle layer is a quartz sand filter layer 7 with a thickness of 800mm, and the lower layer is a composite filter column 3 with a support layer 8 with a thickness of 100mm for filtration. The filtration speed is 8m / h. The filtered water is filtered by the ultrafiltration membrane filter 5, and the mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com