A method for treating fish egg hatching water with ultrasonic and electrocatalytic equipment

An ultrasonic and electrocatalytic technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of water treatment and killing of fish eggs that cannot be hatched, and achieve the effect of improving the hatching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for treating fish egg hatching water with ultrasonic waves in cooperation with electrocatalytic equipment, comprising the following method steps:

[0050] A. Collect fertilized eggs, place them in the water body of a plastic container, add chlorine dioxide to make the available chlorine concentration in the water body reach 4ppm, soak and disinfect for 8 minutes;

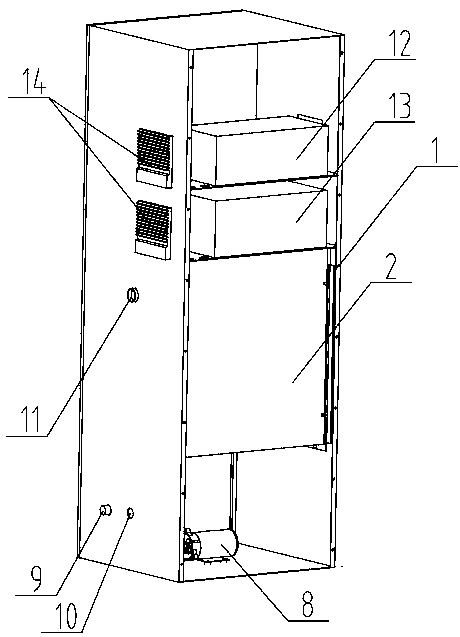

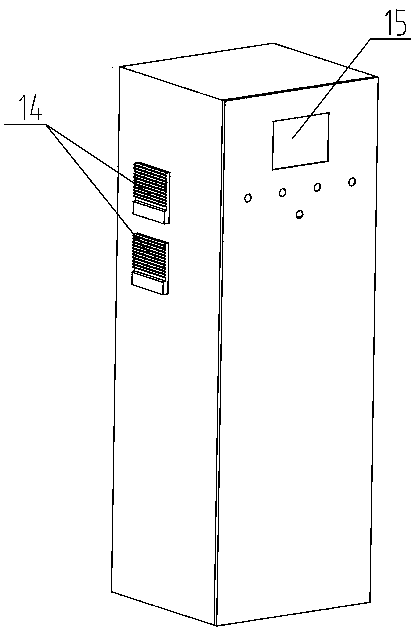

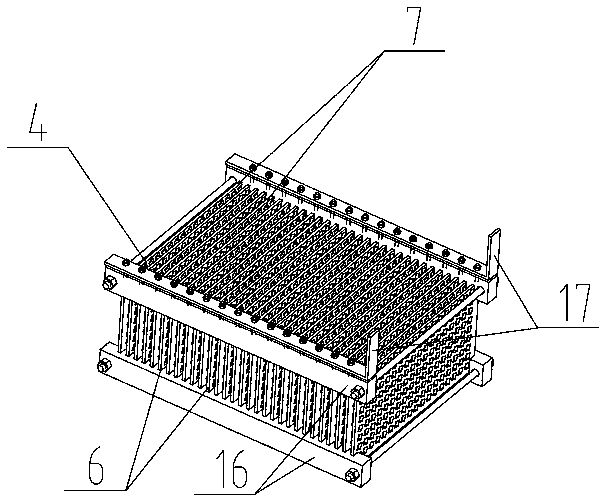

[0051] B. Place an ultrasonic synergistic electrocatalysis device between the hatching water pipeline and the hatching bucket. The device is equipped with a sealed box integrating the ultrasonic generator (3) and the electrolytic generator (4). The ultrasonic generator (3) and the electrolytic generator The device (4) treats the hatching water at the same time, controls the ultrasonic frequency to 28kHz, the ultrasonic power to 100W, controls the power input voltage of the electrolytic generator to 20V, and the current to 30A; the hatching water enters the hatching bucket after being treated;

[0052...

Embodiment 2

[0054] A method for treating fish egg hatching water with ultrasonic waves in cooperation with electrocatalytic equipment, comprising the following method steps:

[0055] A. Collect fertilized eggs, place them in the water body of a plastic container, add chlorine dioxide to make the available chlorine concentration in the water body reach 4ppm, soak and disinfect for 10 minutes;

[0056] B. Place an ultrasonic synergistic electrocatalysis device between the hatching water pipeline and the hatching bucket. The device is equipped with a sealed box integrating the ultrasonic generator (3) and the electrolytic generator (4). The ultrasonic generator (3) and the electrolytic generator The device (4) treats the hatching water at the same time, controls the ultrasonic frequency to 40kHz, the ultrasonic power to 100W, controls the power supply input voltage of the electrolytic generator to be 30V, and the current to be 100A; the hatching water enters the hatching bucket after being tr...

Embodiment 3

[0059] A method for treating fish egg hatching water with ultrasonic waves in cooperation with electrocatalytic equipment, comprising the following method steps:

[0060] A. Collect fertilized eggs, place them in the water body of a plastic container, add chlorine dioxide to make the available chlorine concentration in the water body reach 4ppm, soak and disinfect for 9 minutes;

[0061] B. Place ultrasonic synergistic electrocatalysis equipment between the hatching water pipeline and the hatching barrel. The equipment is equipped with a sealed box integrating the ultrasonic generator (3) and the electrolytic generator (4). The ultrasonic generator (3) and the electrolytic generator At the same time, the device (4) treats the hatching water, controls the ultrasonic frequency to 34kHz, the ultrasonic power to 100W, controls the power input voltage of the electrolytic generator to 25V, and the current to 65A; the hatching water enters the hatching bucket after treatment;

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com