Calcium phosphate bone cement degraded by temperature regulation and its preparation method

A calcium phosphate bone cement and bone cement technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of slow degradation rate, hinder the regeneration and reconstruction of human bone tissue, change the degradation rate of calcium phosphate bone cement, etc., and achieve Easy production, suitable for mass production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

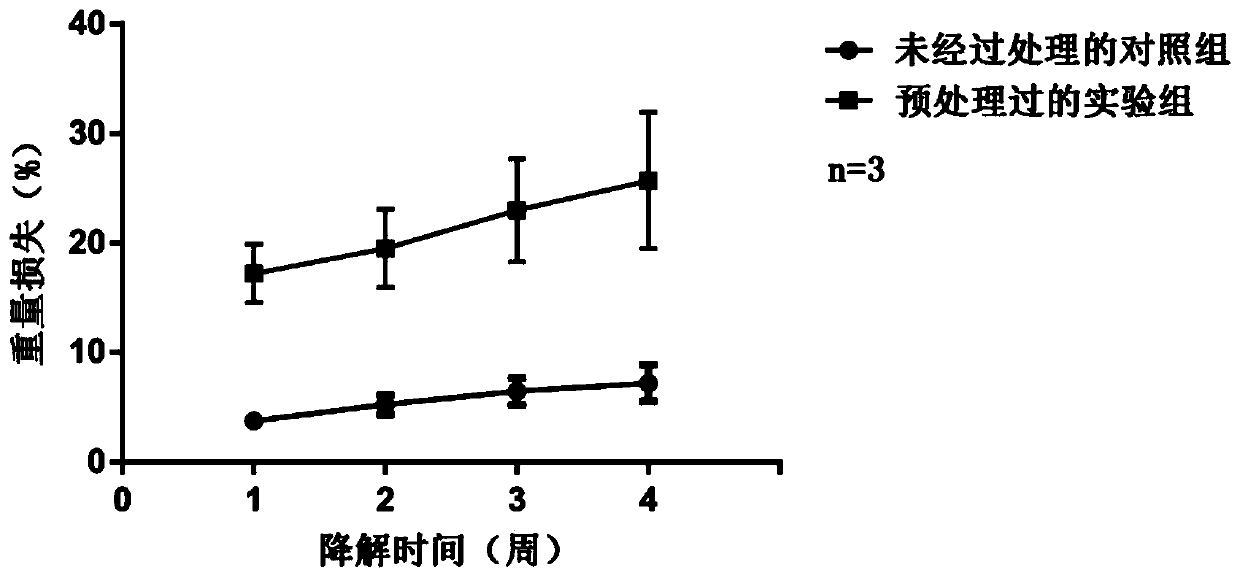

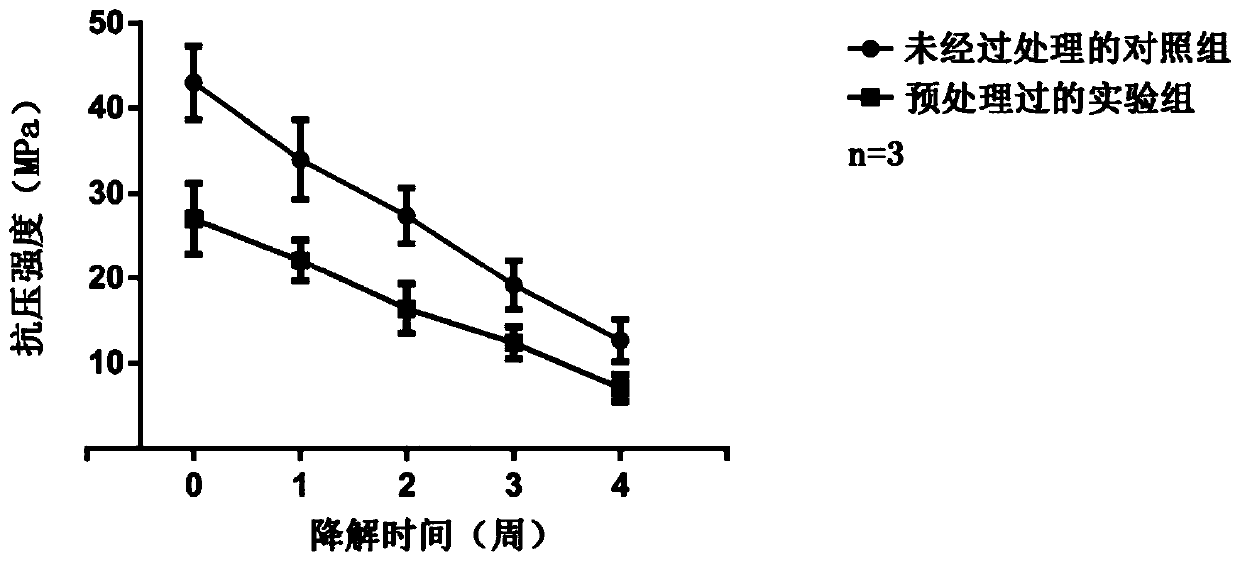

[0029] A calcium phosphate bone cement that is degraded by temperature control, its preparation raw materials include a liquid phase agent and a solid phase powder used in conjunction; the liquid phase agent is a common calcium phosphate bone cement liquid phase agent; the liquid phase agent is common phosphoric acid Calcium bone cement liquid phase agent; the solid phase powder is a mixture of a temperature-sensitive oxygen generating compound and an ordinary calcium phosphate bone cement solid phase powder, wherein the mass fraction of the temperature-sensitive oxygen generating compound in the solid phase powder is 5 %; the ordinary calcium phosphate bone cement is calcium hydrogen phosphate-α-tricalcium phosphate-calcium carbonate system bone cement; the temperature-sensitive oxygen generation compound is a sodium percarbonate-wax microsphere composite with a gelatin layer on the surface wherein, the mass fraction of gelatin in the temperature-sensitive oxygen generation co...

Embodiment 2

[0031] A calcium phosphate bone cement that is degraded by temperature control, its preparation raw materials include a liquid phase agent and a solid phase powder used in conjunction; the liquid phase agent is a common calcium phosphate bone cement liquid phase agent; the liquid phase agent is common phosphoric acid Calcium bone cement liquid phase agent; the solid phase powder is a mixture of a temperature-sensitive oxygen generating compound and an ordinary calcium phosphate bone cement solid phase powder, wherein the mass fraction of the temperature-sensitive oxygen generating compound in the solid phase powder is 1 %; the common calcium phosphate bone cement is a tetracalcium phosphate-α-tricalcium phosphate system bone cement; the temperature-sensitive oxygen generating compound is a sodium percarbonate-wax microsphere compound with a gelatin layer on the surface, wherein , the mass fraction of gelatin in the temperature-sensitive oxygen generation complex is 15%, the sod...

Embodiment 3

[0033] A calcium phosphate bone cement that is degraded by temperature control, its preparation raw materials include a liquid phase agent and a solid phase powder used in conjunction; the liquid phase agent is a common calcium phosphate bone cement liquid phase agent; the liquid phase agent is common phosphoric acid Calcium bone cement liquid phase agent; the solid phase powder is a mixture of a temperature-sensitive oxygen generating compound and an ordinary calcium phosphate bone cement solid phase powder, wherein the mass fraction of the temperature-sensitive oxygen generating compound in the solid phase powder is 20 %; the common calcium phosphate bone cement is tetracalcium phosphate-β-tricalcium phosphate-calcium dihydrogen phosphate system bone cement; The spherical composite, wherein the mass fraction of gelatin in the temperature-sensitive oxygen generating composite is 75%, the sodium percarbonate-wax microsphere composite is a sodium percarbonate microsphere composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com