Glaze and glaze slurry for ceramic elbow water channel without pinhole air bubbles

A technology without pinholes and bubbles, applied in the field of ceramic glaze, can solve the problems of dense pinhole bubbles in curved water channels, reducing the speed of decomposed gas removal, etc., and achieves the improvement of gloss, gloss and smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

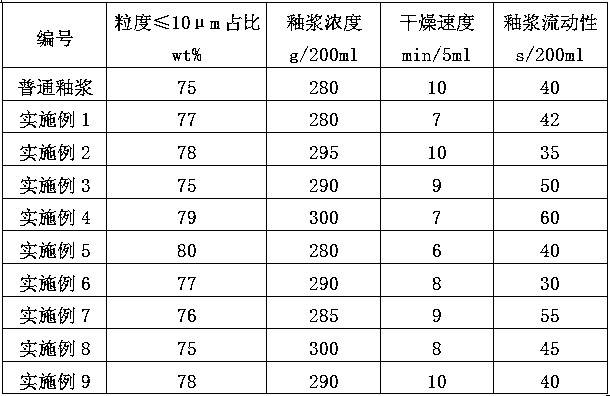

[0013] Embodiments 1-9: The glaze and glaze slurry for the ceramic elbow water channel without pinhole bubbles are as follows.

[0014] The raw material ratio of the glaze in each embodiment, and the ratio of the glaze used for the conventional toilet elbow water channel are shown in Table 1.

[0015] Table 1: Raw material ratio (wt%) of glaze in each embodiment

[0016] Numbering common glaze Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 Example 8 Example 9 albite 22.7 20.0 20.0 19.0 18.0 17.0 18.0 15.0 15.0 15.0 quartz 41.0 20.0 23.0 24.0 20.0 21.0 26.0 20.0 23.0 26.0 Kaolin 8.0 1.5 1.5 1.0 1.5 3.0 1.5 2.5 1.5 2.0 Alumina 2.4 1.0 3.0 4.0 2.0 3.0 4.0 1.0 3.0 3.5 Calcite 16.9 14.0 11.0 9.0 10.0 10.0 9.0 13.0 9.0 9.0 dolomite 6.2 4.0 2.5 1.5 3.0 3.0 1.5 4.0 2.0 1.5 wollastonite 0 7.0 2.0 3.5 4.0 5.0 3.0 7.0 3.5 3.0 Zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com