C20-grade steel-slag-doped recycled aggregate self compact concrete and preparation method thereof

A technology of self-compacting concrete and recycled aggregate, which is applied in the field of building materials, can solve the problems of labor shortage, reduce the production cost of self-compacting concrete, and high cost of construction, and achieve environmental protection, reduce cement production, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

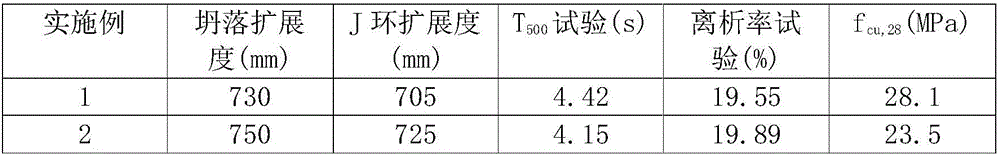

Examples

Embodiment 1

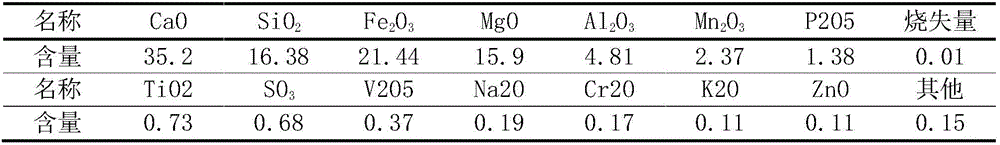

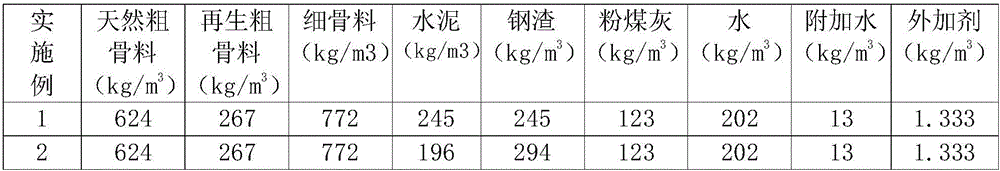

[0029] A kind of C20 grade steel slag mixed with recycled aggregate self-compacting concrete, raw materials in parts by mass: water is 1 part, natural coarse aggregate is 3.089 parts, recycled coarse aggregate is 1.322 parts, fine aggregate is 3.822 parts, cement is 0.970-0.1.213 parts, 1.213-1.455 parts of steel slag, 0.609 parts of fly ash, 0.064 parts of additional water, and 0.00495-0.0124 parts of admixture.

[0030] As a further preference of this solution, the aforementioned steel slag contains 15.9% MgO by mass percentage.

[0031] As a further preference of this solution, the regenerated coarse aggregate is waste concrete containing broken bricks and mortar blocks, which are sorted, crushed and screened to obtain continuously graded regenerated coarse aggregate with a particle size of 5-20 mm.

[0032] As a further preference of this solution, the natural coarse aggregate is continuously graded crushed stone with a particle size of 5-20 mm.

[0033] As a further pref...

Embodiment 2

[0038] The preparation method of C20 grade steel slag mixed recycled aggregate self-compacting concrete is characterized in that it comprises the following steps

[0039] (1) Prepare raw materials

[0040] Cement: P O42.5 ordinary portland cement, apparent density is 3.20g / cm 3 .

[0041] Fly ash: Class I fly ash, the apparent density is 2.42g / cm 3 .

[0042] Fine aggregate: medium-sized river sand with a fineness modulus of 2.4 and a bulk density of 1.54g / cm 3 , the apparent density is 2.64g / cm 3 , the moisture content is 0.35%.

[0043] Steel slag: the steelmaking waste slag that has been placed in the steel mill for more than 6 months has been iron-removed, ball milled and screened, and the steel slag powder with a particle size of less than 0.08mm is selected, and the apparent density is 2.36g / cm 3, the basicity coefficient of steel slag is 1.99, the mass percentage of MgO is 15.9%, and other detection indicators of steel slag are in line with the GB / T 20491-2006 sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com